Large-scale grain depot grain volume weight automatic measuring system and measuring method

An automatic measurement and bulk density technology, which is applied in the field of grain depot inspection, can solve the problems of long-term measurement and low labor efficiency, and achieve the effects of labor saving, convenient centralized processing, and convenient and convenient measurement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

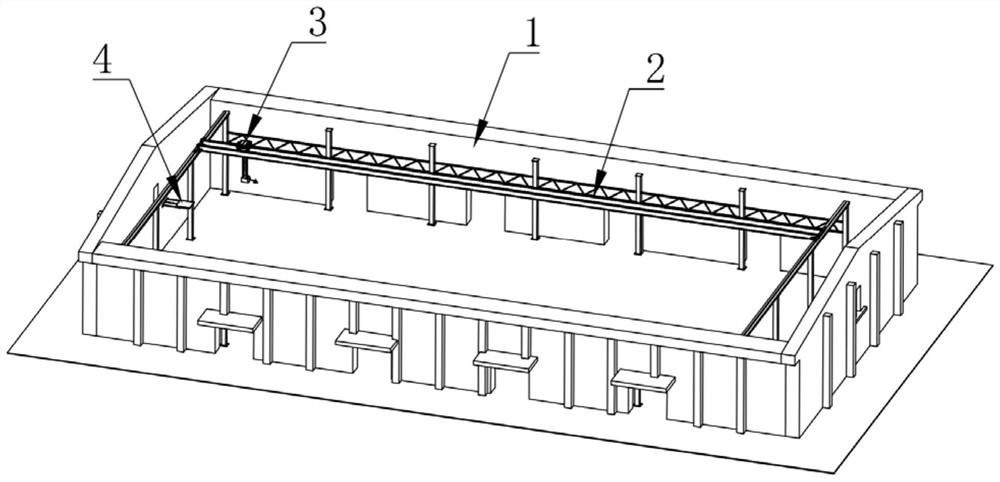

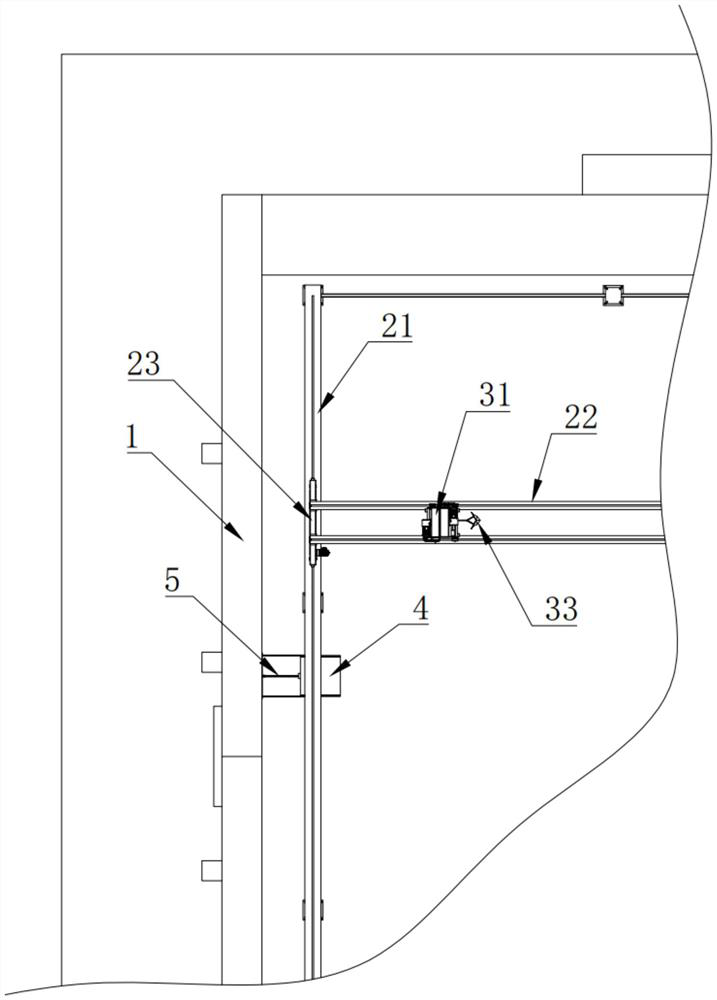

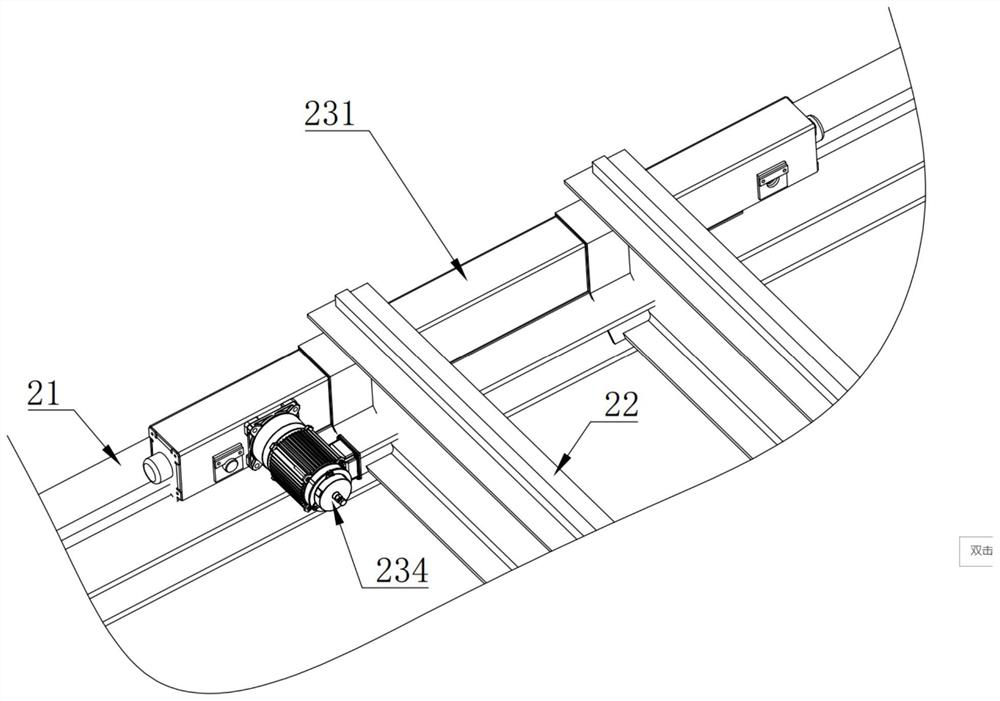

[0036] Such as figure 1 and figure 2 As shown, the embodiment of the present invention provides an automatic measurement system for grain bulk density of a large-scale grain depot, including a grain bin 1, a walking frame 2, a grain fetching device 3 and a weighing device 4, and the specific settings are as follows:

[0037] The granary 1 is mainly used for arranging grain. The walking frame 2 is arranged in the granary 1 to form vertical and horizontal walking tracks on the top of the granary 1. Specifically, the walking frame 2 includes two longitudinal rowing frames 21 and two horizontal rowing frames 22. The two longitudinal rowing frames 21 It is oppositely arranged on both sides of the granary 1, and forms a longitudinal walking track on the top of the granary 1. Two horizontal racks 22 are arranged in parallel, and are erected between the two longitudinal racks 21, and are placed on the top of the granary 1. A horizontal running track is formed, wherein the two ends ...

Embodiment 2

[0046] The embodiment of the present invention provides a kind of automatic measurement method of bulk density, adopts the automatic measurement system of a kind of large-scale grain depot grain bulk density of embodiment 1, comprises the following steps:

[0047] S1. The main control terminal controls the walking component 312 to drive the container 32 to move to the measuring point according to the preset procedure, and controls the lifting component 313 to drive the container 32 to sample the grain at the measuring point;

[0048] S2. Step S1 is repeated at least five times to control the container 32 to sequentially sample at least five different measuring points;

[0049] S3. After the sampling is completed, control the container 32 to move to the top of the grain tank 41, and control the lifting assembly 313 to drive the container 32 to stake out the grain tank 41;

[0050] S4. After the container 32 is set out, the weight sensor 42 weighs the grain in the grain tank 41 ...

Embodiment 3

[0053] The difference from Embodiment 2 is that a method for automatic measurement of bulk density also includes: arranging a plurality of grain depots, arranging a set of automatic measurement systems for bulk density in each grain depot, and setting up a total server, and connecting the total server with each set of bulk density The main control terminal of the automatic measurement system is connected by communication to form a local area communication network. The main control terminal in each grain depot uploads the measured weighing value to the general server, and then the general server uploads it according to the information uploaded by each grain depot. The weighing value is used for mean value calculation and data analysis, so as to facilitate centralized monitoring of the weighing conditions of multiple grain depots.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com