Method for rapidly evaluating performance of weather-resistant steel rust layer for power transmission tower in industrial atmospheric environment

An atmospheric environment, transmission tower technology, applied in weather resistance/light resistance/corrosion resistance, preparation of test samples, measurement devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

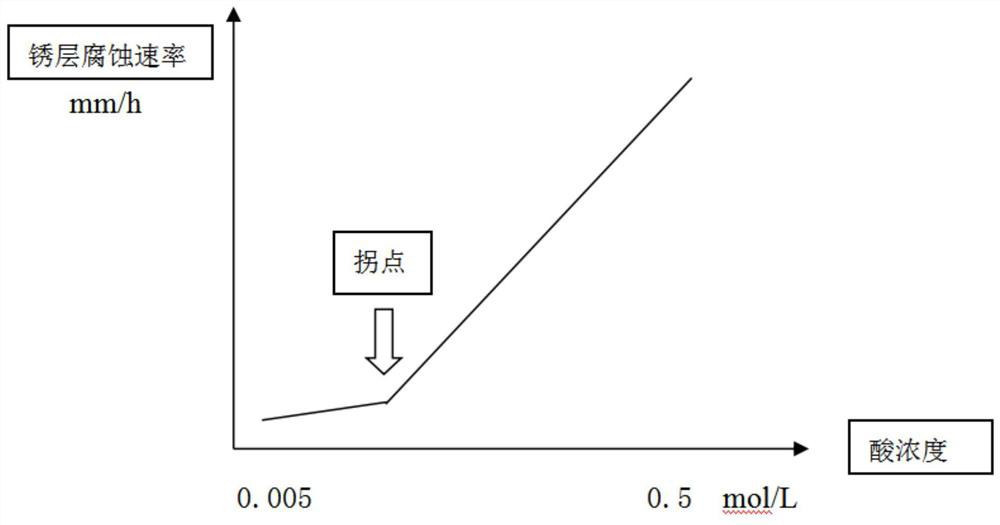

Image

Examples

Embodiment 1

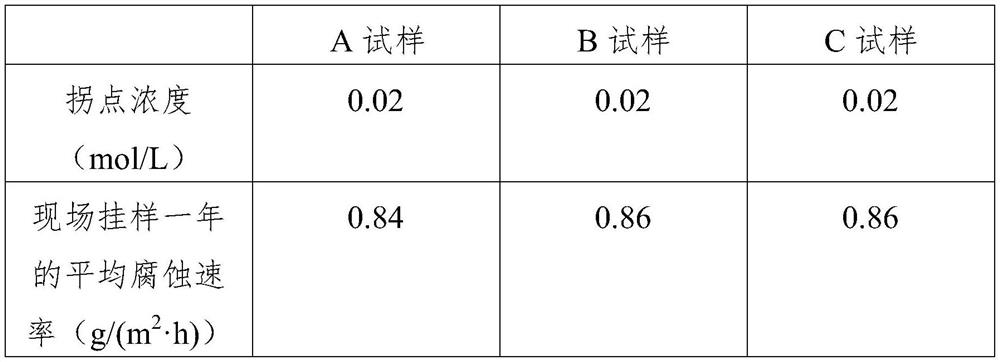

[0032] The weathering steel samples (sample is Q420NTH) with the same chemical composition and three different stabilizing processes, which are respectively A sample, B sample, and C sample, are evaluated by this patent method, and the data are obtained to draw a line graph, and Compared with the test results of the same sample hanging for one year in the industrial atmospheric environment, the comparison results are shown in Table 1 below, where the one-year corrosion rate of the on-site hanging sample in the corrosion rate table is measured by the weight loss method;

[0033] Table 1: Comparison table of test results of three different weathering steel samples with the same chemical composition and different stabilization treatments

[0034]

[0035] Through this method, the corrosion resistance of the three tests is close; thus it can be inferred that the test method and evaluation method of the present invention are consistent with the results of the real corrosion weigh...

Embodiment 2

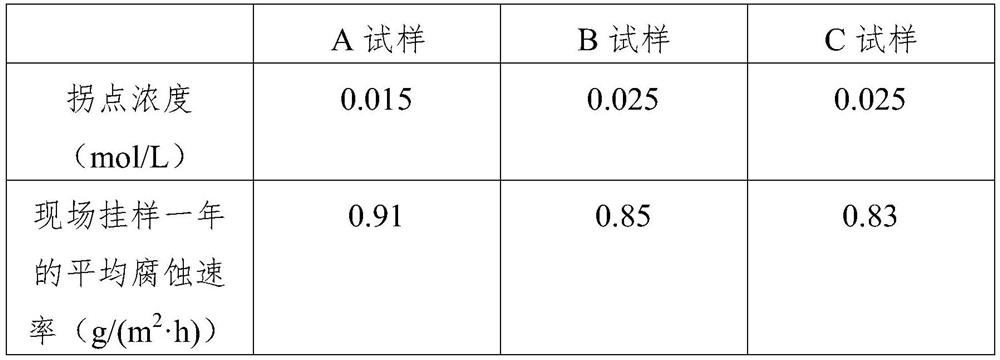

[0037] Three kinds of weathering steel samples (the sample is Q420NTH) with different chemical compositions in the same stabilization treatment process, which are respectively A sample, B sample, and C sample, are evaluated by this patent method, and the data are drawn to draw a line graph, and Compared with the test results of the same sample hanging for one year in the industrial atmospheric environment, the comparison results are shown in Table 2 below, where the corrosion rate of the on-site hanging sample for one year in the corrosion rate table is measured by the weight loss method;

[0038] Table 2: Comparison table of test results of three different weathering steel samples with the same stabilization treatment process and different chemical compositions

[0039]

[0040] By this method, the performance of sample A is the worst; thus it can be inferred that the test method and evaluation method of the present invention are consistent with the real corrosion weight lo...

Embodiment 3

[0042] The weathering steel samples (sample is Q420NTH) of 3 different manufacturers with the same stabilization treatment process, respectively A sample, B sample, and C sample, are evaluated by this patent method, and the data obtained are drawn as line graphs, and compared with The test results of the same sample hanging for one year in the industrial atmospheric environment are compared, and the comparison results are shown in Table 3 below, where the corrosion rate of the one-year hanging sample in the corrosion rate table is measured by the weight loss method;

[0043] Table 3: Comparison table of test results of three different weathering steel samples with the same stabilization treatment process and different chemical compositions

[0044]

[0045]

[0046] By this method, the performance of the sample A sample is better, and the performance of the sample C is relatively poor; thus it can be inferred that the test method and evaluation method of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com