Method for rapidly detecting oxidative rancidity expiration date of grease-containing products

A technology of shelf life and oil, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of long strengthening cycle and low accuracy, and achieve the effect of quantitative detection of shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

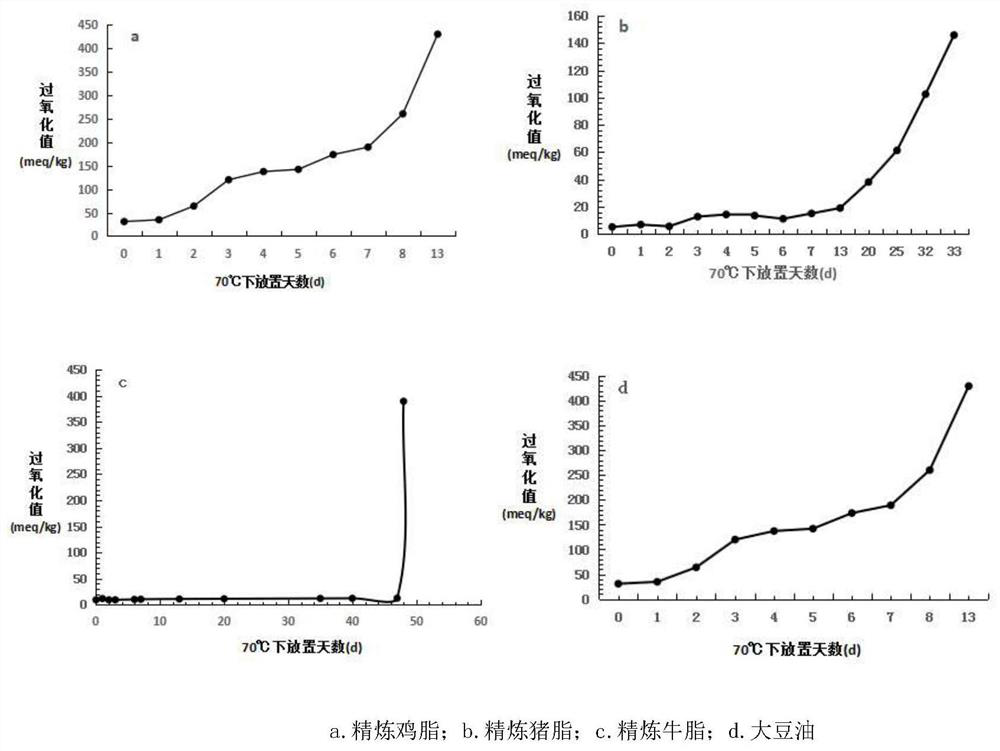

[0030] (1) Accurately weigh 200g of the oil sample, put the refined chicken fat into a 500mL triangular flask, cover the bottle mouth with 6 layers of white cloth and 1 layer of kraft paper, tie the mouth with cotton rope, place it in a constant temperature oven, and set the temperature The temperature range is 70°C, and samples are taken every day until the sensory evaluation fails, and the samples obtained every day are stored in a -4°C refrigerator, and the peroxide value is measured uniformly after the intensive test is completed

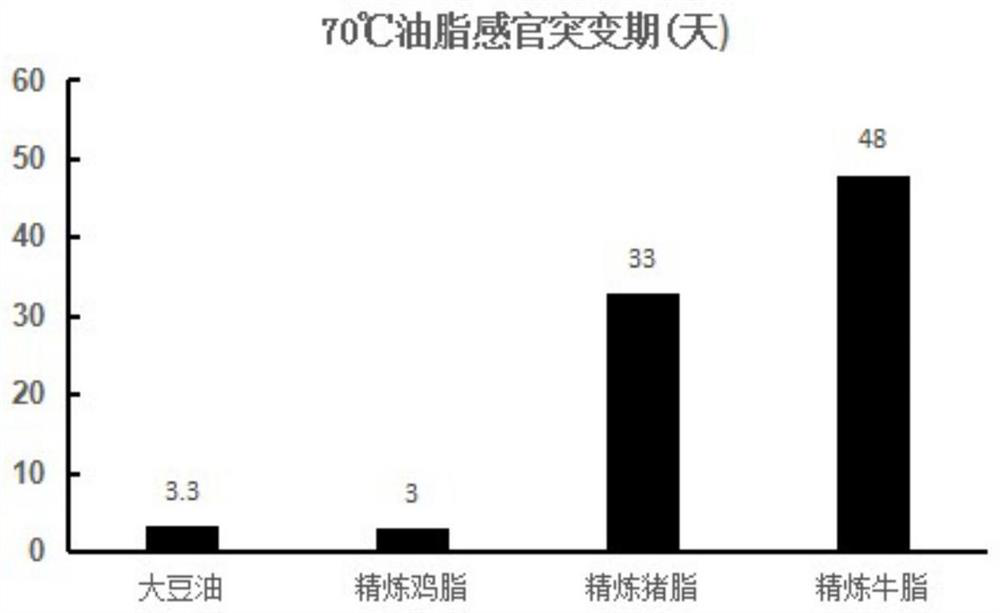

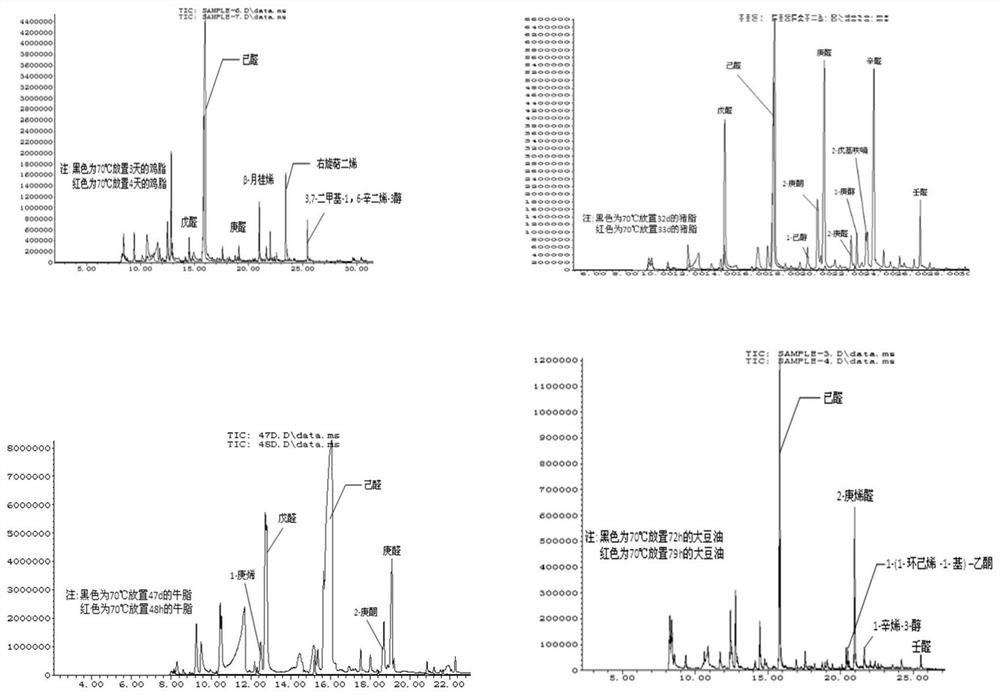

[0031] (2) Perform GC-MS headspace quality analysis on the refined fat sample obtained in (1) and the oil sample from the previous day, and compare and analyze the gas spectrum components of the above two samples, and the sensory evaluation matches the gas quality analysis judgment , determined the sensory mutation of refined chicken fat placed at 70°C for 3 days

[0032] (3) Construction of the Oxidation Habor Model for Products Containing Refi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com