A method for active suppression of vibration and noise of permanent magnet synchronous motor

A permanent magnet synchronous motor, vibration and noise technology, applied in the direction of motor control, motor generator control, AC motor control, etc., can solve the problems of cycle-by-cycle adjustment, complex curve fitting function, loss of high-frequency information, etc., to achieve Improve the effect of torque ripple and electromagnetic vibration noise, improve the quality of PWM modulation wave, and increase the frequency of data update

Active Publication Date: 2022-05-31

CSSC SYST ENG RES INST

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] Patent Document 3 (CN105577059B) discloses a noise suppression method for a marine asynchronous motor system, which calculates the electromagnetic torque ripple of a three-phase motor under different loads and different speeds offline, draws q curves, and performs online closed-loop control of the motor At this time, the theoretical value of electromagnetic torque ripple under the current speed and load is calculated, and compared with the actual value of electromagnetic torque ripple of the current motor, and the output voltage compensation value is compared through the PI regulator, but this method has a curve fitting function Complex so that digital implementation is difficult and low-pass filtering leads to loss of high-frequency information and other issues

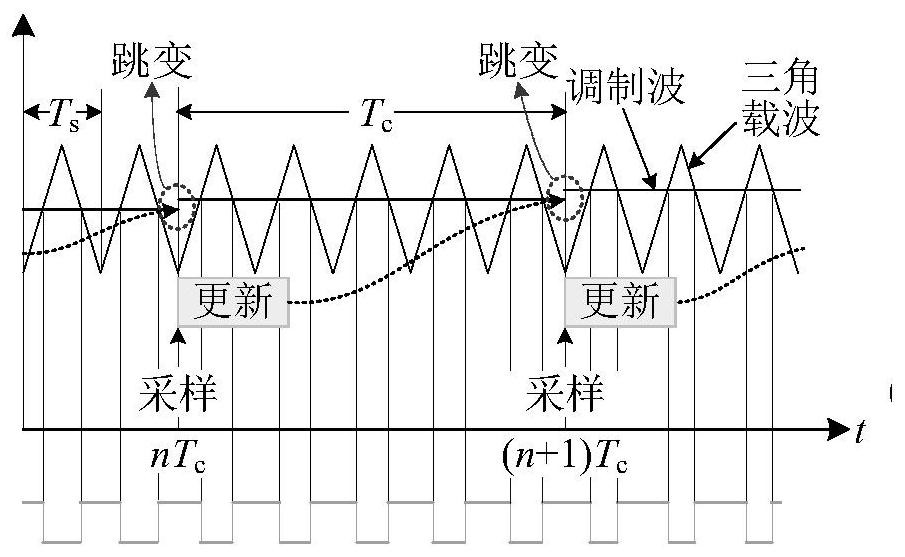

[0007] From the perspective of discrete control of embedded digital controllers, DSP, MCU or FPGA are commonly used in the field of variable frequency motor drive. Taking TIC2000 series DSP as an example, due to the need to deal with sampling, PID control, protection and other links, the main frequency and switching frequency of the controller must be Satisfy a certain ratio, and the timer interrupt requires a certain execution time. With the increase of the switching frequency, it is basically impossible to use cycle-by-cycle adjustment when the switching frequency is above tens of kHz. Therefore, it takes several switching cycles to complete a control cycle at high frequencies. , digital delay caused by multi-cycle adjustment makes it difficult to design a high-bandwidth controller. Although the switching frequency has been increased, the dynamic performance has not reached the same level, and at the same time it has brought problems such as zero-crossing distortion and variable jumps. The controller does not take care of the processing or compensation, resulting in torque ripple at the control frequency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0066] ω

[0076]

[0077]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

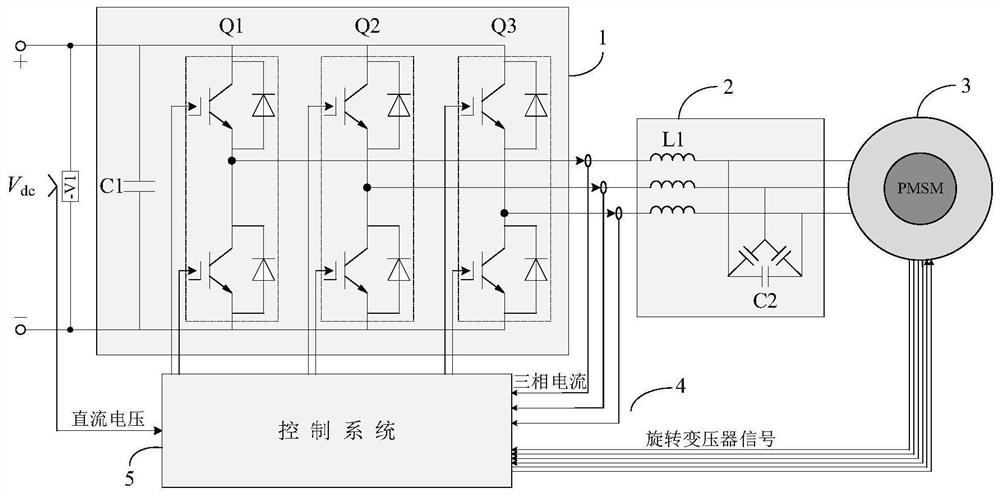

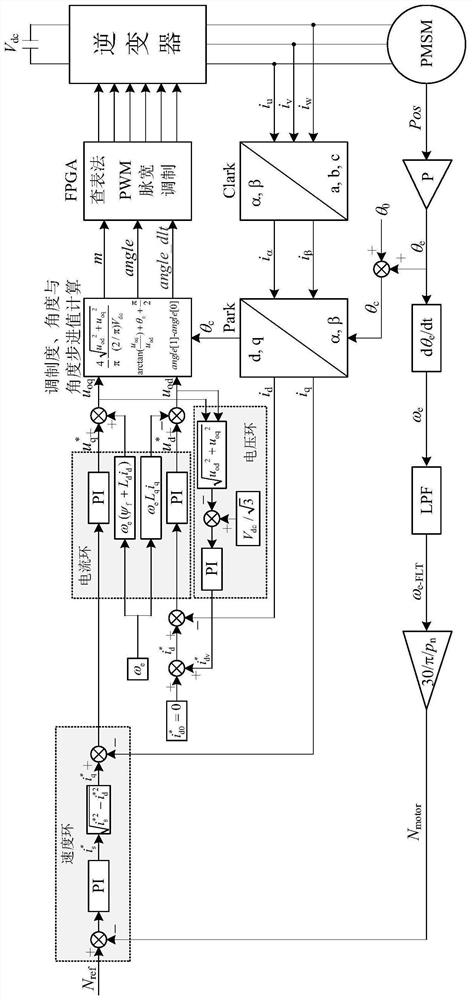

The invention discloses a method for actively suppressing the vibration noise of a permanent magnet synchronous motor. Based on the DSP+FPGA embedded control system architecture, the DSP timer is interrupted to complete the sampling process and closed-loop control and obtain the modulation degree and angle real-time instructions. For the angle jump variable between adjacent sampling points, the virtual high-frequency method is used to calculate the angle step value, and the modulation command is sent to the FPGA through the high-speed data bus. Taking advantage of its fast operation speed, the modulation amplitude value in one control cycle, etc. Efficiently linearize stepping to the command value, and use clock synchronization to ensure the reliable clearing of the counter and stepper buffer, and then generate a smooth modulation wave and compare it with the triangular carrier wave to output PWM pulses to drive the inverter to convert the DC bus voltage into The three-phase AC voltage drives the motor to run, thereby realizing the multi-sampling fine-grained control of key variables, significantly improving the variable update frequency and control accuracy, avoiding variable jumps, and effectively improving the torque ripple and electromagnetic vibration noise of the motor.

Description

A method for active suppression of vibration and noise of permanent magnet synchronous motor technical field The invention belongs to the alternating current motor vibration control technical field, particularly a kind of ship permanent magnet synchronous motor digital control The method of suppressing high frequency vibration noise of the controller. Background technique Permanent magnet synchronous motor has the advantages of high power density, simple mechanical structure, high efficiency in the whole speed regulation range and torque output. It has the advantages of high ratio and has been widely used in major equipment such as energy power, transportation, and high-end manufacturing. With the wide range of permanent magnet motors It is widely used, and its vibration and noise characteristics have attracted more and more attention. Among them, ship propulsion, high-precision servo and electric vehicles, etc. High-end applications have an extremely urgent need f...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H02P21/05H02P21/06H02P21/14H02P21/22H02P6/10H02P25/026H02P27/08

CPCH02P21/05H02P21/06H02P21/14H02P21/22H02P6/10H02P25/026H02P27/085H02P2207/05Y02T10/64

Inventor 杜会卿杨森蔡宗举刘玉明蔡道萌张智杰苗春晖

Owner CSSC SYST ENG RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com