Full-automatic sugarcane peeling, cleaning and sectioning equipment

A fully automatic, cutting technology, applied in the peeling of vegetables or fruits, metal processing, food processing, etc., can solve the problems of cumbersome inconvenience, easy to be cut by hands and other problems, and achieve the effect of reducing the difficulty of operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

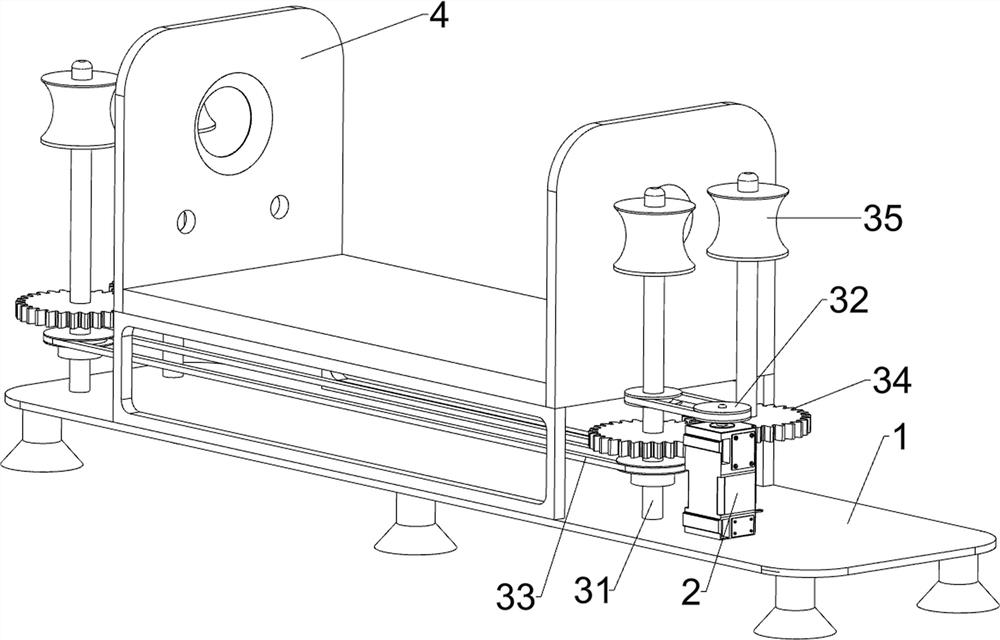

[0060] A fully automatic sugarcane peeling, cleaning and sectioning equipment, such as figure 1 As shown, it includes a bottom plate 1, a gear motor 2, a feeding assembly 3, a support frame 4 and a peeling assembly 5. A gear motor 2 is installed on the right front side of the bottom plate 1, and a feeding assembly is arranged between the left and right sides of the bottom plate 1. 3. The feeding assembly 3 is connected to the output shaft of the reduction motor 2, the bottom plate 1 is provided with a support frame 4 in the middle, and the upper left side of the support frame 4 is provided with a peeling assembly 5.

[0061] When people want to peel sugarcane automatically, they can use this fully automatic sugarcane peeling, cleaning and cutting equipment. First, people put a piece of sugarcane from the left side of the feeding assembly 3, start the deceleration motor 2, and the deceleration motor 2 outputs The shaft rotation drives the feeding assembly 3 to operate, thereby ...

Embodiment 2

[0063] On the basis of Example 1, such as figure 2 and image 3 As shown, the feeding assembly 3 includes a first rotating shaft 31, a first transmission device 32, a second transmission device 33, a first spur gear 34 and a roller 35, and the bottom plate 1 is provided with a first rotating shaft 31 in a rotating manner on the front, rear, left, and right sides. A first transmission device 32 is connected between the first rotating shaft 31 on the right front side of the bottom plate 1 and the output shaft of the geared motor 2, and a second transmission device 33 is connected between the two first rotating shafts 31 on the front side. The bottom of the rotating shaft 31 is provided with a first spur gear 34 , the two first spur gears 34 on the left side mesh with the two first spur gears 34 on the right side, and the top of the first rotating shaft 31 is provided with a roller 35 .

[0064] People put the sugarcane between the two rollers 35 on the left side. After startin...

Embodiment 3

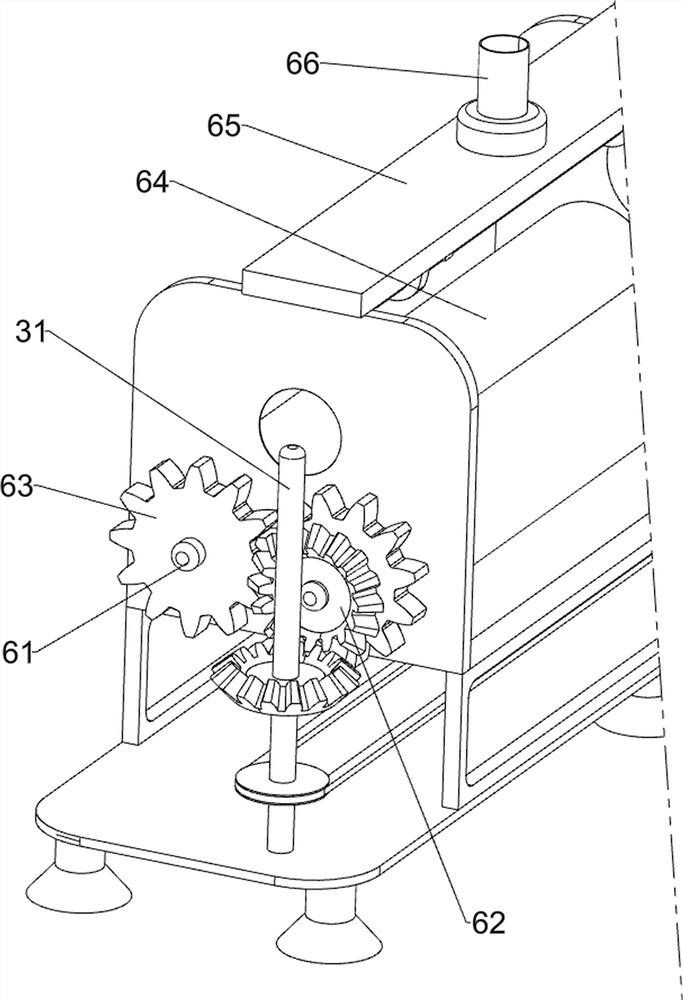

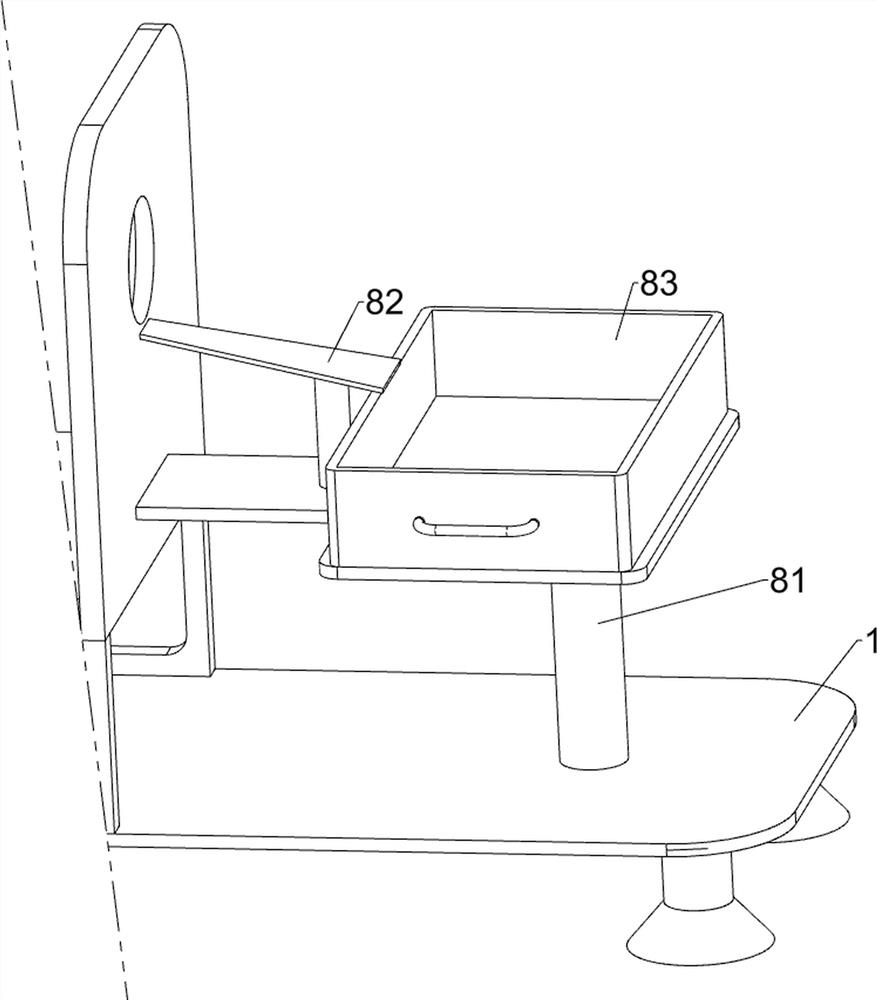

[0068] On the basis of Example 2, such as Figure 4-7 As shown, a cleaning assembly 6 is also included, and the cleaning assembly 6 includes a second rotating shaft 61, a bevel gear set 62, a second spur gear 63, a rolling brush 64, a support plate 65, a water pipe 66 and a U-shaped pipe clamp 67, and a support frame 4. A second shaft 61 is rotatably connected to the front and rear sides of the middle part. A bevel gear set 62 is arranged between the second shaft 61 on the front side and the first shaft 31 on the front side of the left part. The left side of the two second shafts 61 is A second spur gear 63 is provided, and the two second spur gears 63 are meshed. Rolling brushes 64 are set on the two second rotating shafts 61. A support plate 65 is connected between the left and right sides of the top of the support frame 4. The middle part of the support plate 65 is provided with a The water pipe 66 and the left and right sides of the bottom of the support plate 65 are provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com