Torreya grandis production drying device for food processing

A food processing and drying device technology, applied in food processing, application, food science, etc., can solve the problem of high drying cost, achieve the effects of reducing cost, improving practicability, and preventing excessive temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

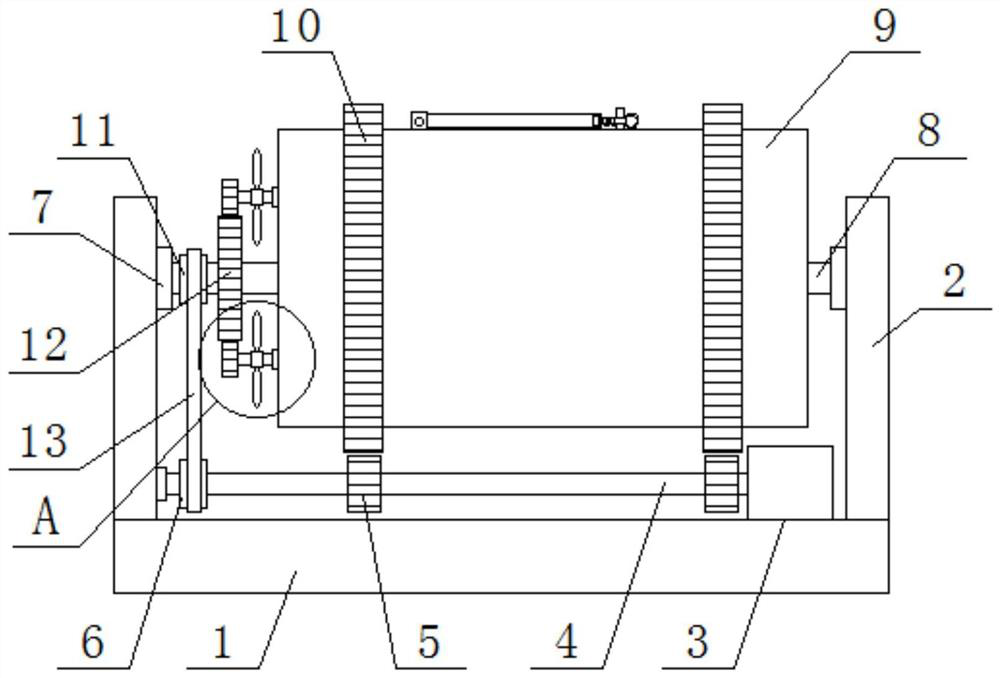

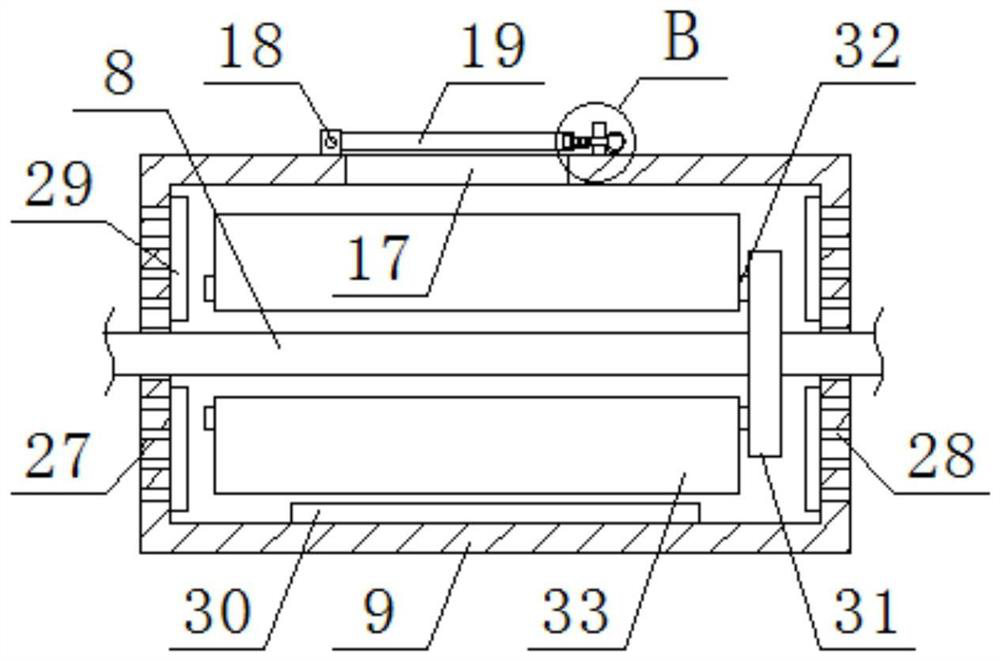

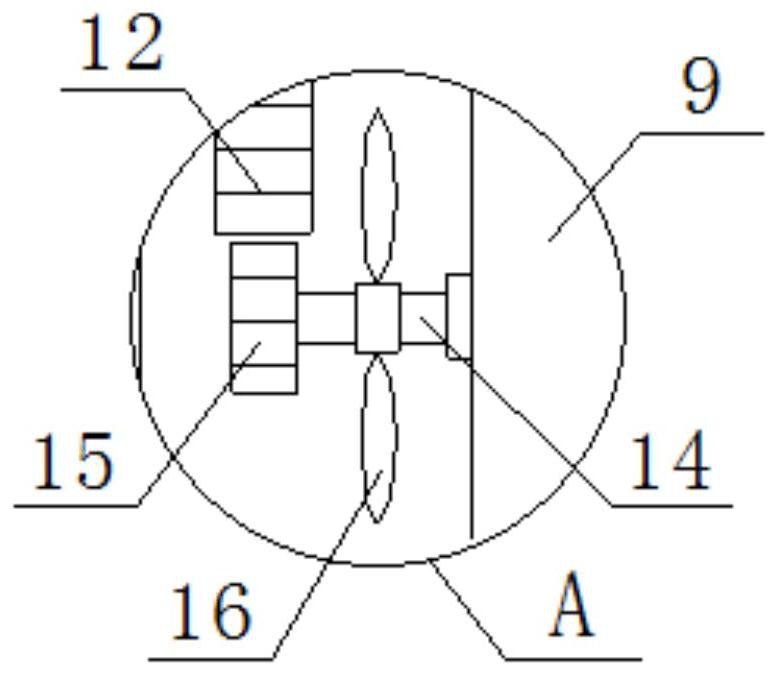

[0024] refer to Figure 1-5 , a production and drying device for Chinese torreya for food processing, comprising a base 1, side plates 2 are fixedly installed on both sides of the top of the base 1, and a side plate between the two side plates 2 is fixedly installed on one side of the top of the base 1 The motor 3, the output shaft of the motor 3 is fixedly equipped with a rotating rod 4, and the end of the rotating rod 4 away from the motor 3 is rotated and installed on the side plate 2, and the rotating rod 4 is fixedly sleeved with two first gears 5 and a first chain Wheel 6, bearings 7 are fixedly installed on the side where the two side plates 2 are close to each other, and the bearings 7 are located above the motor 3, and the same first rotating shaft 8 is fixedly installed in the two bearings 7, and the first rotating shaft 8 is close to the motor One end of 3 is rotatably sleeved with a drum 9 , and the end of the first rotating shaft 8 away from the motor 3 is fixedly...

Embodiment 2

[0026] In the present invention, two gear rings 10 are fixedly sleeved on the drum 9, and the two gear rings 10 are respectively meshed with two first gears 5, and the rotation of the first gear 5 can drive the gear rings 10 to rotate, thereby driving the drum 9 turn.

[0027] In the present invention, the same chain 13 is sleeved between the first sprocket 6 and the second sprocket 11 , and the rotation of the first sprocket 6 can drive the second sprocket 11 to rotate through the chain 13 .

[0028] In the present invention, the second gear 12 is located between the two third gears 15 , and the two third gears 15 are both meshed with the second gear 12 , the rotation of the second gear 12 can drive the rotation of the two third gears 15 .

[0029] In the present invention, a moving rod 22 is slidably installed in the through hole 21 , and both ends of the moving rod 22 extend out of the through hole 21 , and the moving rod 22 can slide horizontally along the through hole 21 ...

Embodiment 3

[0034] refer to Figure 1-5 , a production and drying device for Chinese torreya for food processing, comprising a base 1, side plates 2 are fixedly installed on both sides of the top of the base 1, and a side plate between the two side plates 2 is fixedly installed on one side of the top of the base 1 The motor 3, the output shaft of the motor 3 is fixedly equipped with a rotating rod 4, and the end of the rotating rod 4 away from the motor 3 is rotated and installed on the side plate 2, and the rotating rod 4 is fixedly sleeved with two first gears 5 and a first chain Wheel 6, bearings 7 are fixedly installed on the side where the two side plates 2 are close to each other, and the bearings 7 are located above the motor 3, and the same first rotating shaft 8 is fixedly installed in the two bearings 7, and the first rotating shaft 8 is close to the motor One end of 3 is rotatably sleeved with a drum 9 , and the end of the first rotating shaft 8 away from the motor 3 is fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com