Anti-blocking controllable multi-channel chip removal device for multi-station numerical control machine tool

A technology for CNC machine tools and chip removal devices, which is applied to metal processing mechanical parts, manufacturing tools, metal processing equipment, etc., can solve the problems of reducing the chip removal efficiency of the chip removal structure and reducing the use time of the chip removal device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

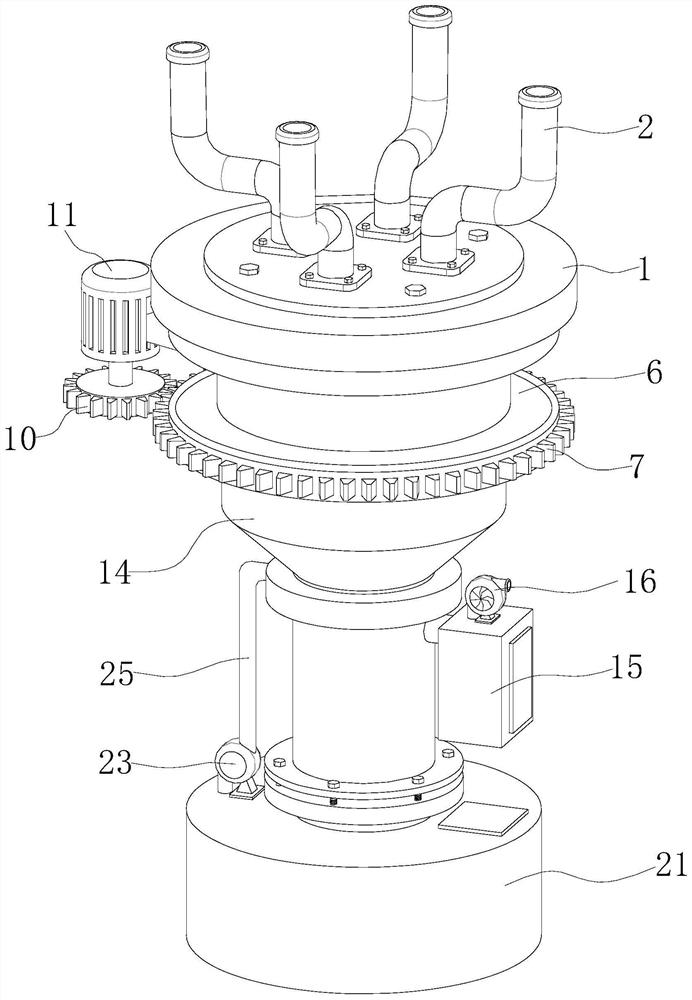

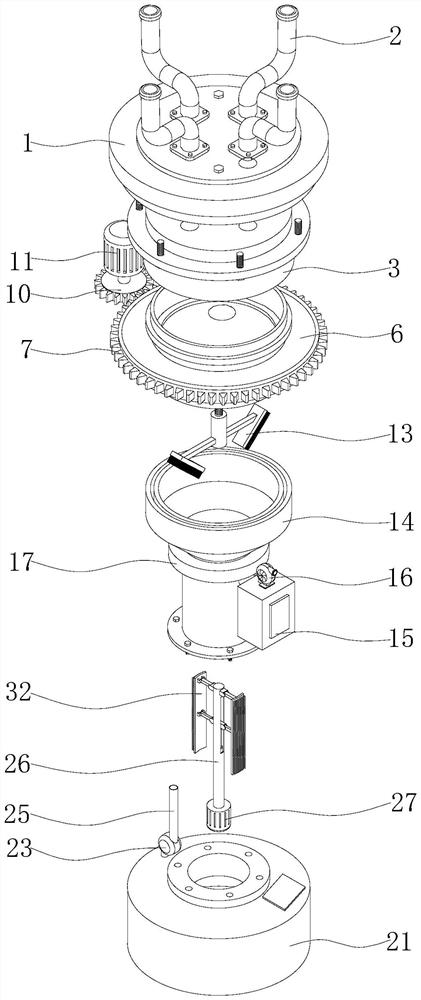

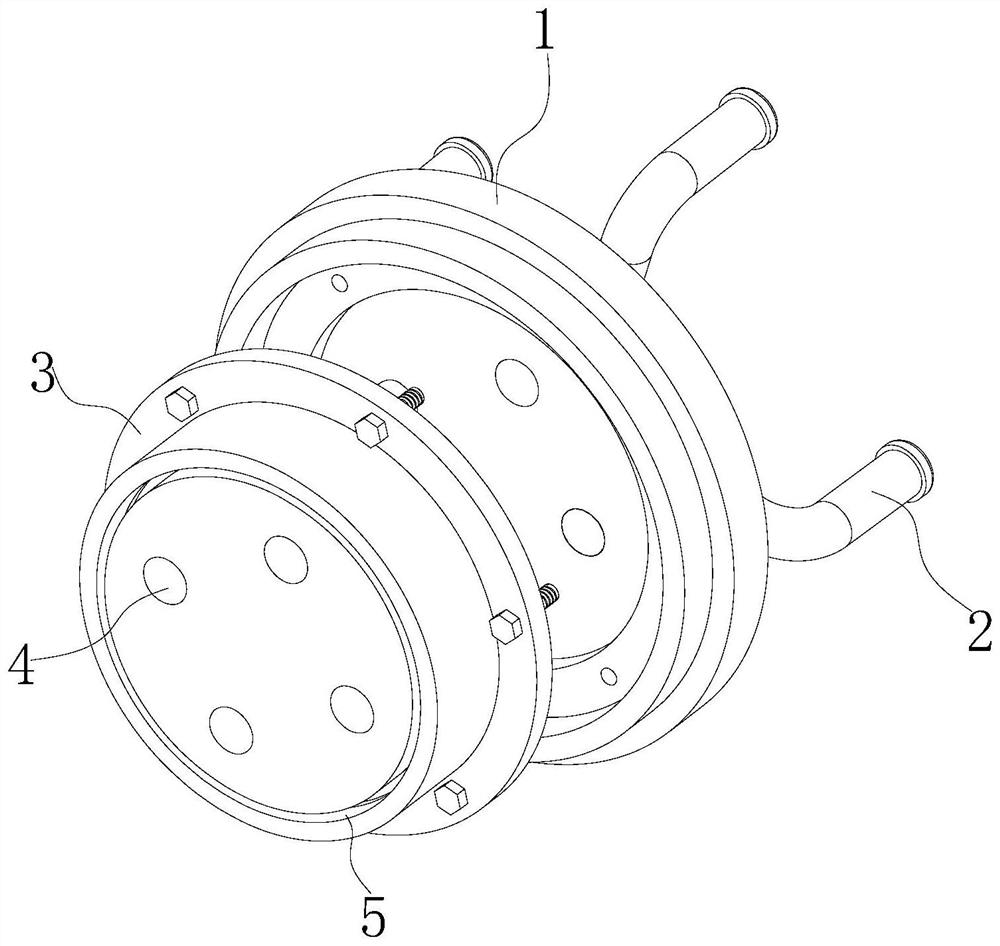

[0032] Such as Figure 1-9As shown, the present invention provides a technical solution: an anti-clogging controllable multi-channel chip removal device for multi-station CNC machine tools, including a connection plate 1, a chip removal pipe 2 connected to the top of the connection plate 1, and a connection plate 1 The bottom of the inner sleeve 3 is fixedly installed, the inside of the inner sleeve 3 is provided with a through hole 4, the bottom of the inner sleeve 3 is provided with a mounting groove 5, and the inside of the mounting groove 5 is sleeved with a drum 6, and the drum 6 A ring gear 7 is fixedly installed on the outside, a partition 8 is fixedly installed inside the drum 6, and a chip discharge hole 9 is opened inside the partition 8, and a driving gear 10 is meshed on one side of the ring gear 7, and the bottom of the drum 6 is covered with Connected with a cleaning tube 14, one side of the cleaning tube 14 is connected with a storage box 15, and the top of the ...

Embodiment 2

[0035] Such as Figure 1-9 As shown, on the basis of the first embodiment, the present invention provides a technical solution: the number of the through holes 4 and the chip discharge pipe 2 are the same, and the positions are corresponding, and the diameter of the chip discharge hole 9 is larger than the diameter of the through hole 4 .

[0036] In this embodiment, the chip discharge pipes 2 are evenly and symmetrically distributed on the top of the connection plate 1, the number of chip discharge pipes 2 can be set according to the specific number of workpiece processing devices, and the number of through holes 4 and chip discharge pipes 2 is always maintained Equal and corresponding in position, such setting can improve the range of use of the device, and can perform chip removal on multiple workpiece processing devices to achieve the effect of multi-channel chip removal. , it can ensure that the dust passing through the dust pipe 2 can completely enter the inside of the c...

Embodiment 3

[0038] Such as Figure 1-9 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the top of the cleaning cylinder 14 is provided with an installation groove 5, the installation groove 5 includes an annular connection groove 501, and one side of the annular connection groove 501 Connected with an annular slot 502, the drum 6 includes a fixed plate 601, the top and bottom of the fixed plate 601 are fixedly installed with an annular connecting plate 602, one side of the annular connecting plate 602 is fixedly installed with an annular protrusion 603, and the annular connecting plate 602 Socketed inside the annular connecting groove 501, and the annular connecting plate 602 is compatible with the specification and size of the annular connecting groove 501, the annular protrusion 603 is sleeved inside the annular locking groove 502, and the annular protrusion 603 and the annular locking groove 502 size fits.

[0039] In this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com