Nested industrial assembly mechanical gripper

A mechanical claw, nested technology, applied in the direction of manipulators, manufacturing tools, chucks, etc., can solve the problems of high energy consumption, large use area, and robots are easy to "fight", and achieve the effect of stable and reliable grasping and reduced damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the examples, but the present invention is not limited to the following examples.

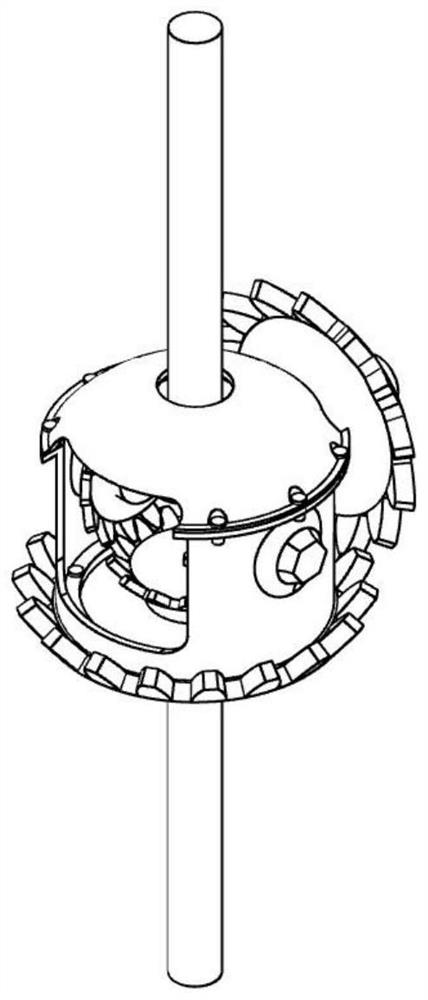

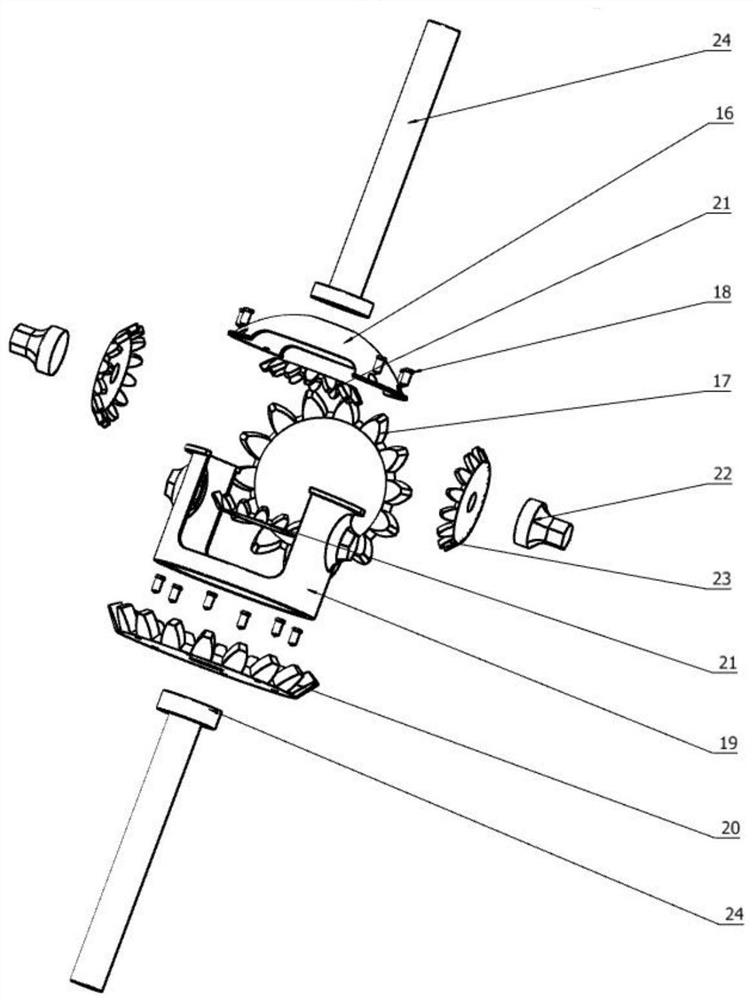

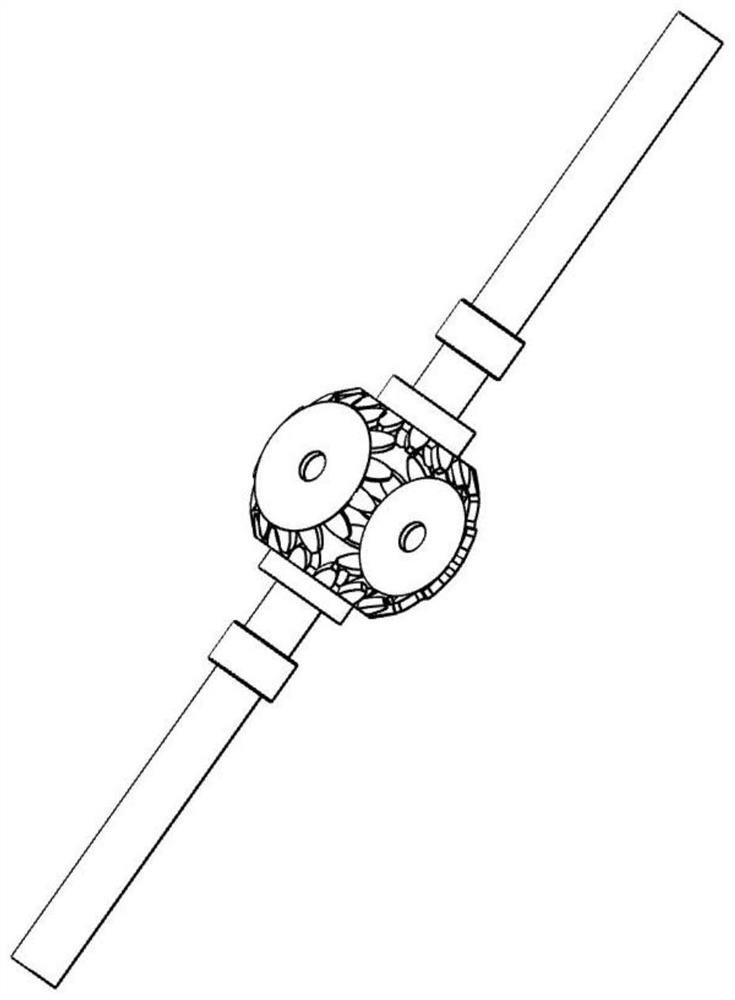

[0041] Nested industrial assembly mechanical claws are a set of assembly mechanical claws that are used in the assembly of industrial parts in factories and integrate transportation parts and fixed parts. Its overall mechanical structure can be divided into two parts: "nested structure mechanical claw" and "gravity adjustment mechanical arm body".

[0042] The nested structure mechanical claw is the main part of the present invention, and the outer layer is a three-claw mechanical claw. The three-claw structure is similar to the shape of a parallel hydraulic linkage rod, and can realize self-adaptive grasping and conversion between two modes of quasi-parallel assembly. , the claw head part is designed with a fine-tuning self-adaptive mechanism, which can realize self-adaptive grasping of the surface of the part, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com