One-driving-two water ring granulation and dehydration system for plastic production

A water ring granulation and plastic technology, applied in the field of plastic production, can solve the problems of uncontrollable plastic release, reduced practicality, and reduced dehydration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

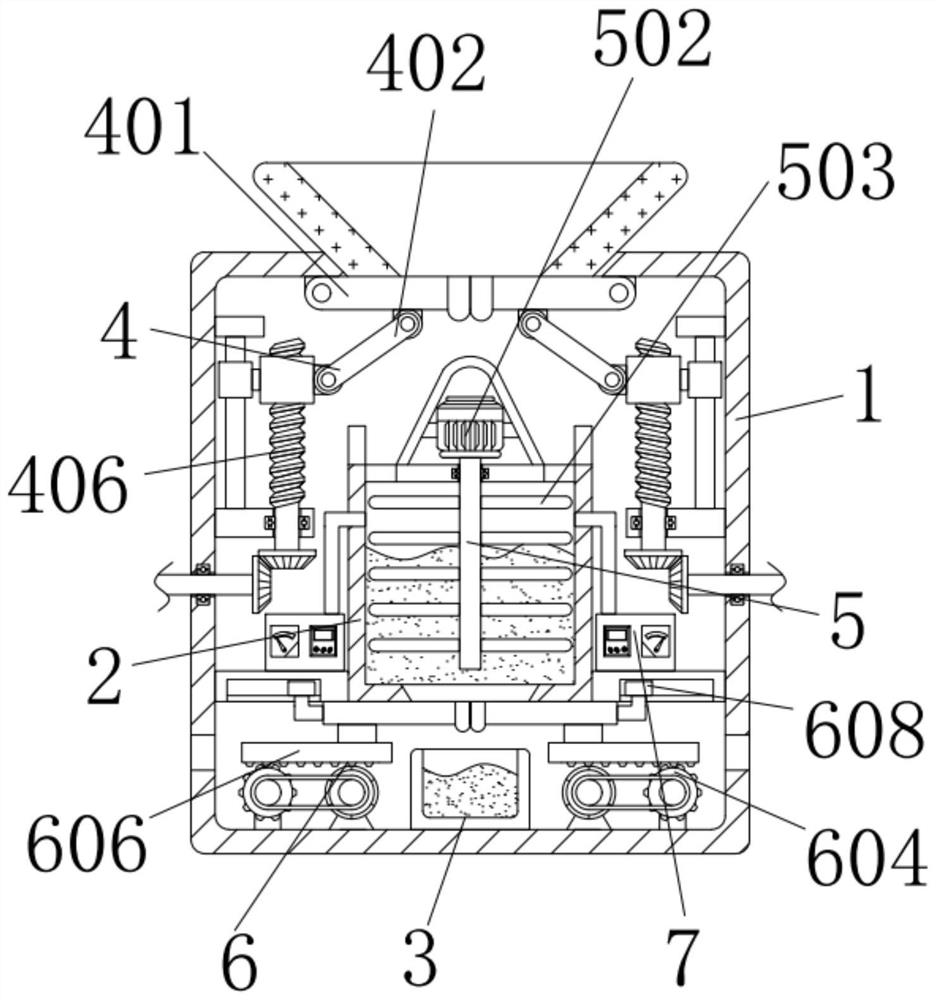

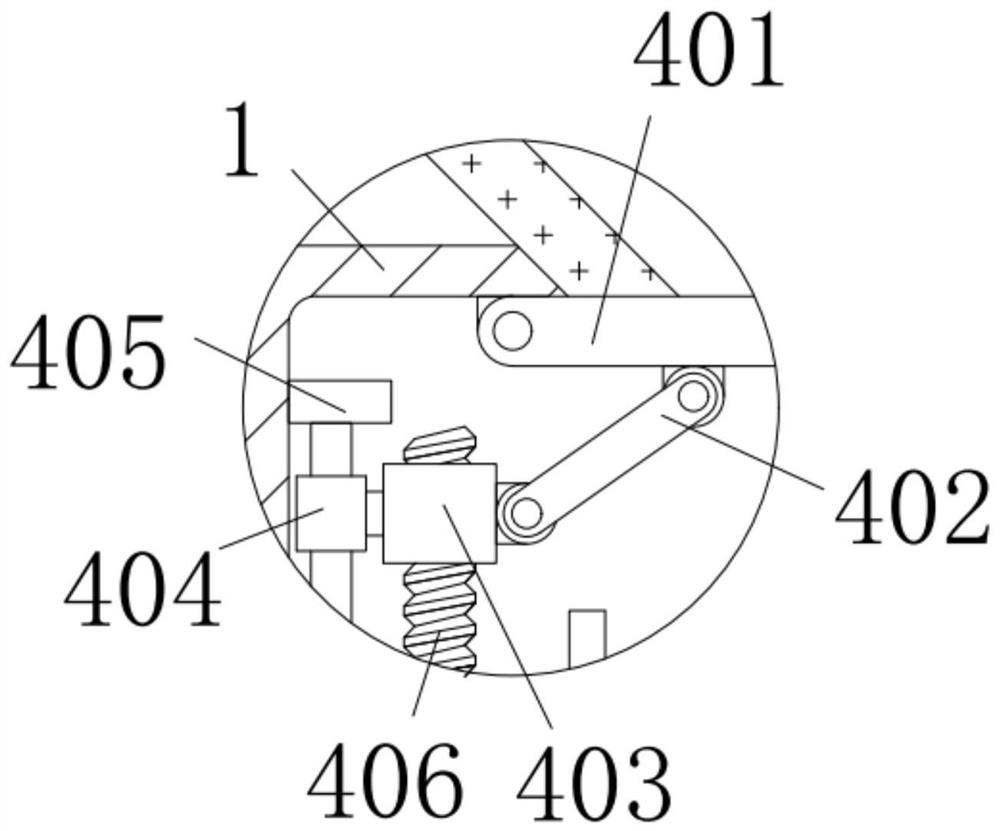

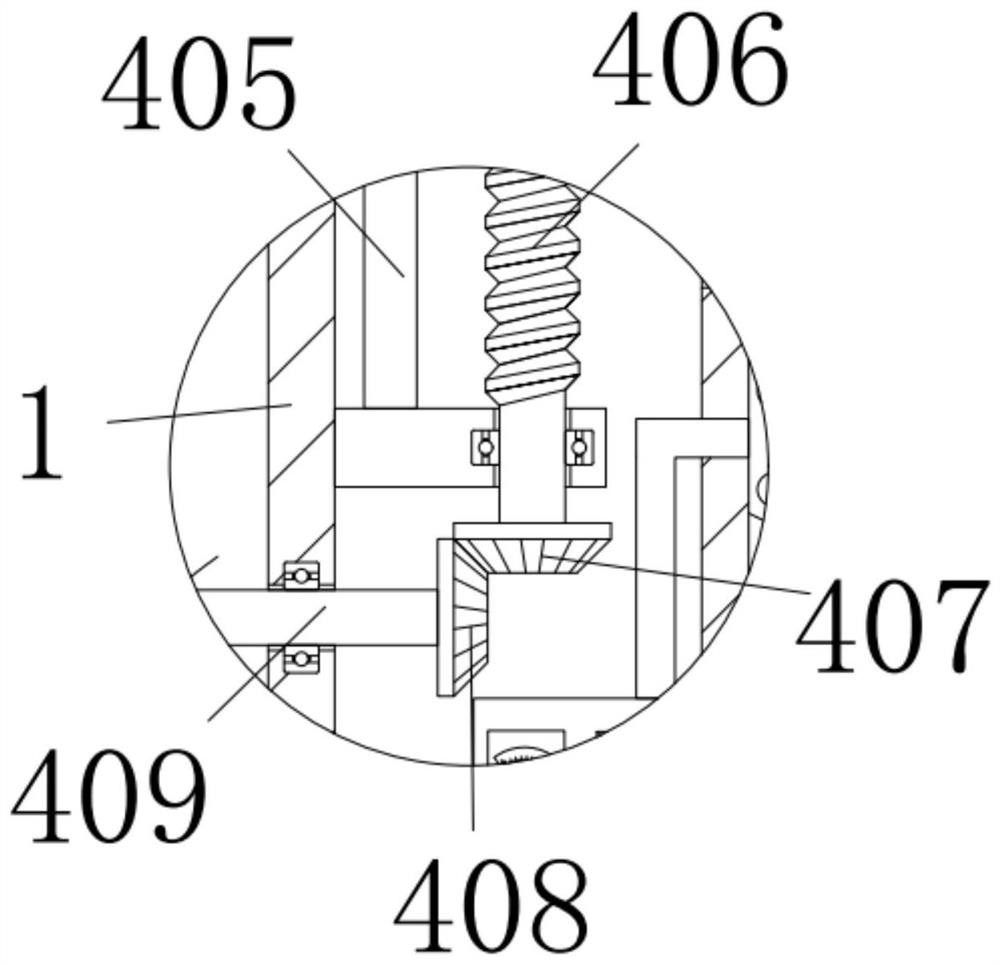

[0032] A one-to-two water ring granulation and dehydration system for plastic production, including a casing 1, a casing 2, a material box 3 and a hot air blower 7, the casing 1 is provided with a casing 2, and the top of the casing 2 is processed with a through hole, and the raw material Through here, the left and right sides of the inner wall of the housing 2 are fixedly connected with the lower left and right sides of the inner wall of the housing 1, and a material box 3 is arranged below the inner wall of the housing 1, and the bottom of the material box 3 is attached to the bottom of the inner wall of the housing 1 Together, two hot air blowers 7 are arranged on the left and right sides of the top of the shell 2. The model of the hot air blowers 7 is HAG-HP3A-21. The bottoms of the two hot air blowers 7 are fixedly connected with the left and right sides of the top of the shell 2. The output end of the fan 7 runs through the top left and right sides of the housing 2, and t...

Embodiment 2

[0034] As an option, see figure 1 , 4And 5, a one-to-two water ring granulation and dehydration system for plastic production, the inside of the housing 1 is provided with a stirring device 5, the stirring device 5 includes a curved plate 501, a first motor 502, a stirring rod 503, the bottom of the curved plate 501 and The top of the shell 2 is fixedly connected, the inside of the curved plate 501 is provided with a first motor 502, the model of the first motor 502 is ECMA-E11320RS, the outer wall of the first motor 502 is fixedly connected with the left and right sides of the inner wall of the curved plate 501 through brackets, The bottom of the first motor 502 is provided with a stirring rod 503, the top of the stirring rod 503 is fixedly connected to the output end of the first motor 502, and the top of the outer wall of the stirring rod 503 is connected to the top of the housing 2 through bearings for rotation;

[0035] The solution in this embodiment can be selectively ...

Embodiment 3

[0037] As an option, see figure 1 and 6 , plastic production with one drag two water ring granulation dehydration system, the lower part of the shell 1 is provided with a feeding device 6, the feeding device 6 includes a second motor 601, a first sheave 602, a second sheave 603, a second sheave 603, Three gears 604, vertical plates 605, racks 606, straight plates 607 and sliders 608, the bottom of the second motor 601 is fixedly connected to the bottom of the inner wall of the housing 1 through a bracket, and the output end of the second motor 601 is fixedly connected with the first groove Wheel 602, the model of the second motor 601 is ECMA-E11320RS, the outer wall of the first sheave 602 is connected with the second sheave 603 through belt rotation, the back pin shaft of the second sheave 603 is fixed with the third 604, the third The back side of the gear 604 is connected with a riser 605 through the rotation of the pin shaft. The bottom of the riser 605 is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com