Automatic washing method and system for SLA three-dimensional printing workpiece

A technology of three-dimensional printing and cleaning system, which is applied in the direction of manufacturing tools, additive processing, metal processing equipment, etc., can solve problems such as no solution, low degree of automation, and high pressure on environmental protection, and achieve broad industry application prospects and automation high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

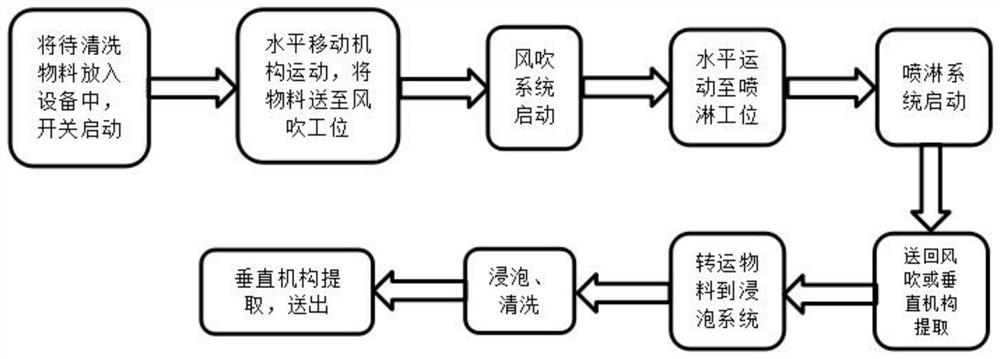

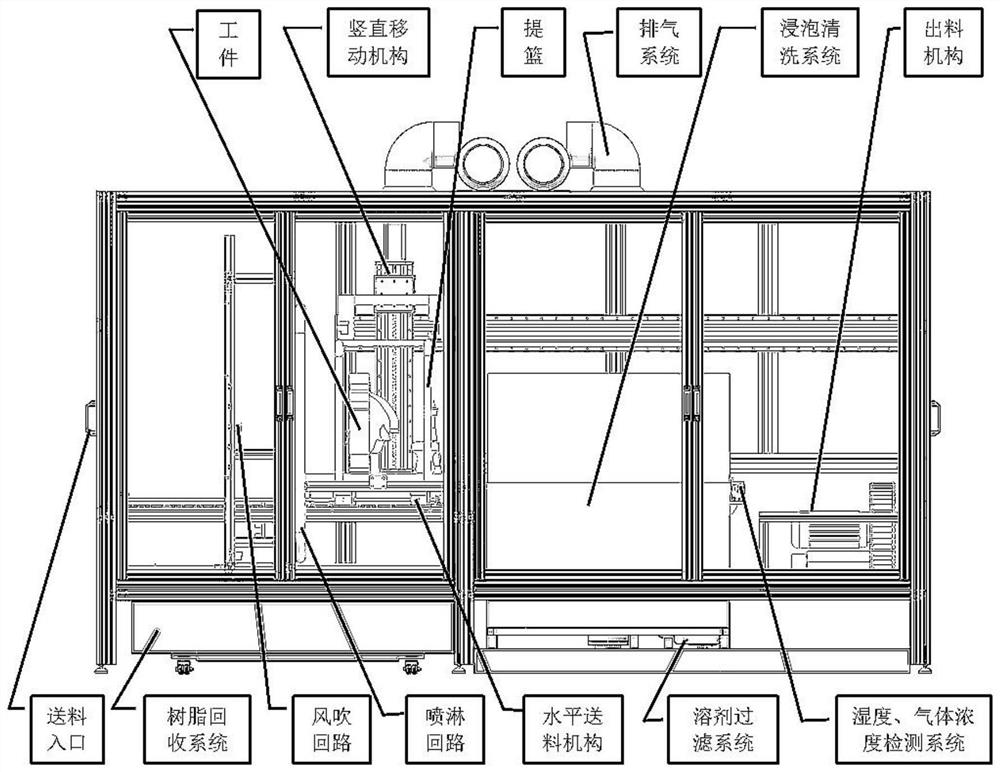

[0037] According to the preparation method of an automatic cleaning equipment for SLA three-dimensional printing provided by the present invention, the preparation process is as follows: figure 1 shown, including the following steps:

[0038] Step 1: Put the workpiece printed by the SLA equipment into the cleaning equipment as a whole or dispersedly;

[0039] Step 2: Select a plan with a workpiece height of 200 or more. After starting the equipment, the horizontal feeding mechanism will automatically send the workpiece to the blowing station;

[0040] Step 3: Wind blowing strategy According to the characteristics of the workpiece, adopt the large air volume mode and repeat the wind blowing for 8 cycles, which can clean 70% of the residual resin;

[0041] Step 4: Send it to the spray station, adopt the intermittent spray mode, spray for 10 seconds, and at the same time, the workpiece moves repeatedly;

[0042] Step 5: Liquid attachment and scouring can further clean the surfa...

Embodiment 2

[0048] Step 1: Put the workpiece printed by the SLA equipment into the cleaning equipment as a whole or dispersedly;

[0049] Step 2: Select the workpiece plan with a height of less than 200mm. After starting the equipment, the horizontal feeding mechanism will automatically send the workpiece to the blowing station;

[0050] Step 3: The wind blowing strategy adopts the medium air volume mode according to the characteristics of the workpiece, and automatically adjusts the distance between the blowing outlets to a closer position, and repeats the wind blowing for 5 cycles, which can clean 75% of the residual resin;

[0051] Step 4: Send it to the spray station, adopt the continuous spray mode, spray for 5 seconds, and at the same time, the workpiece moves repeatedly;

[0052] Step 5: Liquid attachment and scouring can further clean the surface of the workpiece, and the cleanliness can reach 90% at this time;

[0053] Step 6: Grasp by the vertical mechanism, and then move horiz...

Embodiment 3

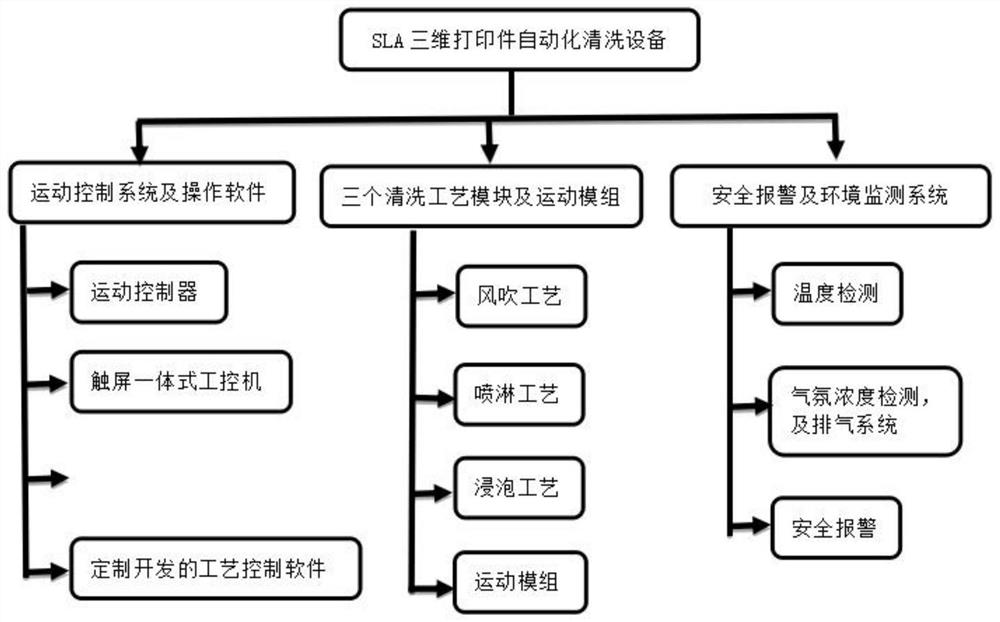

[0058] The automatic cleaning system of the SLA three-dimensional printing workpiece provided according to the present invention includes:

[0059] Module M1: Removal of residual resin on the surface by wind blowing process;

[0060] Module M2: use spraying process to further clean the residual resin on the surface of the workpiece;

[0061] Module M3: Use soaking process to thoroughly clean the workpiece;

[0062] Module M4: Using an automated material delivery platform, the workpiece is automatically transported and cleaned in the whole process from loading to cleaning.

[0063] Preferably, the wind blowing process includes: through four high-pressure air pipes with a diameter of 2mm, blowing the surface of the workpiece with a wind pressure of 0.6MPa, and at the same time reciprocating the material delivery platform, and removing the residual resin on the surface of the workpiece by wind pressure .

[0064] Preferably, the spraying process includes: using a 6L / min, 10bar p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com