Dual-motor torque vectoring system, control method and automobile

A technology of torque vectoring and control methods, applied in control devices, vehicle components, electric power devices, etc., can solve problems such as limited motor power, inability to use two-wheel drive models, and restrictions on two-wheel drive models, so as to achieve low difficulty in system control, The effect of mature technology and process and high degree of generalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

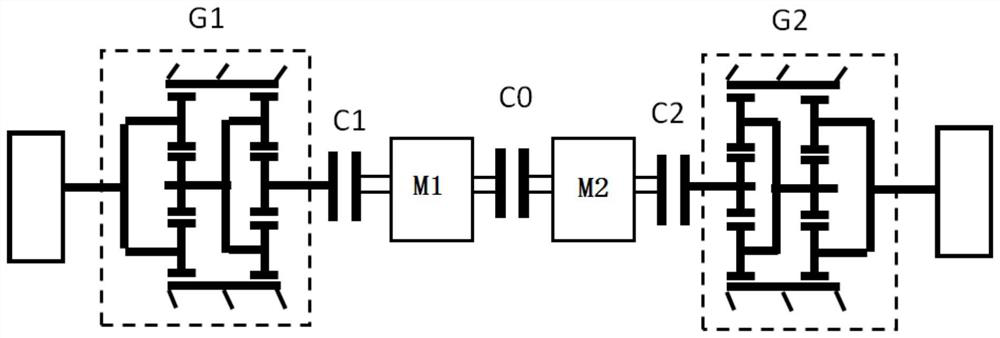

[0067] Such as figure 1 As shown, the high-efficiency coaxial dual-motor torque vectoring system mechanism of this embodiment includes a first motor M1, a second motor M2, a first double-row planetary mechanism G1, a second double-row planetary mechanism G2, a third clutch C0, The first clutch C1 and the second clutch C2.

[0068] Among them, the first motor M1, the second motor M2, the first double-row planetary mechanism G1, the second double-row planetary mechanism G2, the third clutch C0, the first clutch C1, and the second clutch C2 are packaged and arranged inside the bridge (Fig. The remainder of the bridge system is not shown).

[0069] Specifically, the rotor shaft of the first motor M1 is connected to the input end of the first double-row planetary mechanism G1 through the first clutch C1, and the rotor shaft of the second motor M2 is connected to the input end of the second double-row planetary mechanism G2 through the second clutch C2. The rotor shaft of the firs...

Embodiment 2

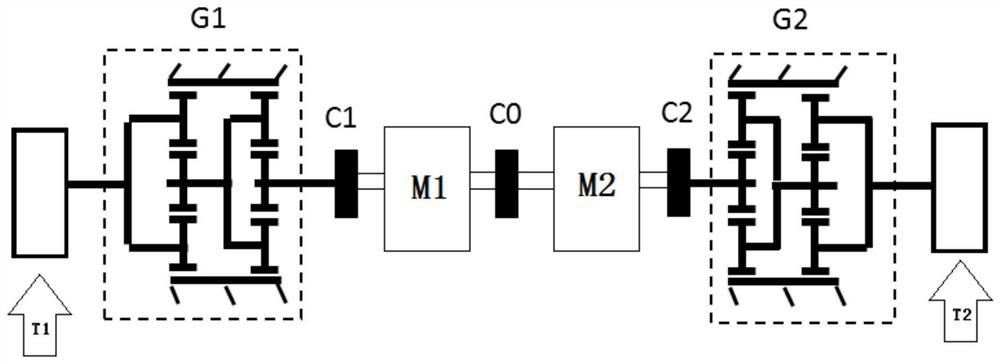

[0071] Refer below figure 2 , describing an embodiment of a control method for a coaxial dual-motor torque vectoring system under different operating conditions.

[0072] Such as figure 2 As shown, a high-efficiency coaxial dual-motor torque vectoring system single-motor drive vehicle driving control method is disclosed, which is suitable for the normal straight-going situation of the vehicle. The third clutch C0 is closed, the first clutch C1 is closed, and the second clutch C2 is closed, the first motor M1 participates in driving and the second motor M2 does not work (or the second motor M2 participates in driving and the first motor M1 does not work), the power is respectively The transmission is transmitted to the left and right wheels through the first double-row planetary mechanism G1 and the second double-row planetary mechanism G2 to drive the vehicle to travel.

[0073] In addition, if figure 2 As shown, it can also be applied to the control method when there is...

Embodiment 3

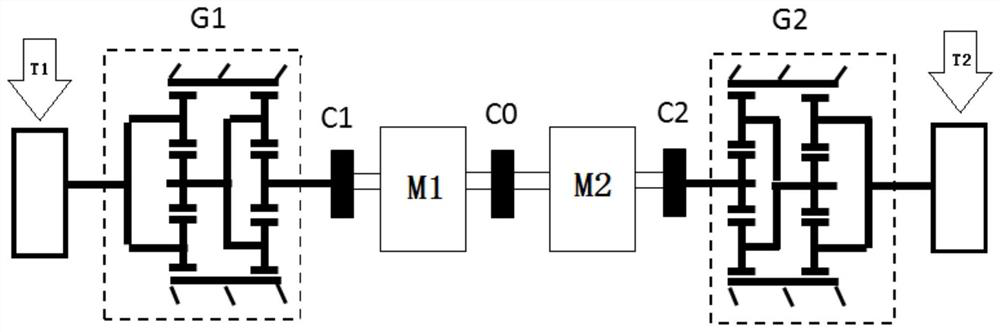

[0077] Such as image 3 As shown, this embodiment is an energy recovery control method for a high-efficiency coaxial dual-motor torque vectoring system, which is applicable to the situations of coasting energy recovery and braking energy recovery.

[0078] 1) Coasting energy recovery: During the coasting process of the vehicle when the driver releases the accelerator, the third clutch C0 is closed, the first clutch C1 is closed, and the second clutch C2 is closed, and the negative torque provided by the first motor M1 (or the second motor M2) is controlled. The transmission is transmitted to the left and right wheels through the first double-row planetary mechanism G1 and the second double-row planetary mechanism G2 respectively, so that the vehicle decelerates and slides, and ensures that the first motor M1 or the second motor M2 works in a high-efficiency area to generate electricity as much as possible, so that Efficient recovery of vehicle sliding energy.

[0079] 2) Brak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com