Railway vehicle and installation method of cab hood thereof

A technology for rail vehicles and driver's cabs, which is applied in the field of installation of rail vehicles and their driver's cab hoods, can solve the problems of inability to adopt such a connection structure, deformation of the driver's cab hood, and the existence of prestress, so as to improve reliability and reliability. The effect of vehicle safety, guaranteed life and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

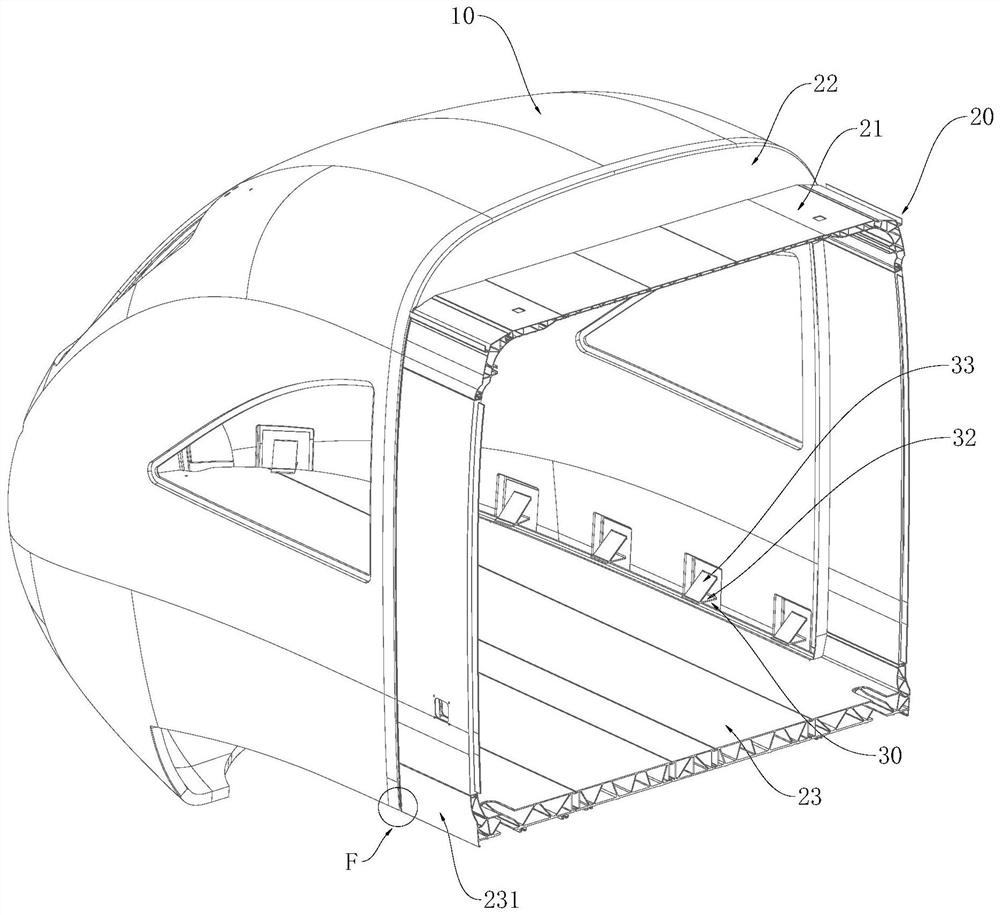

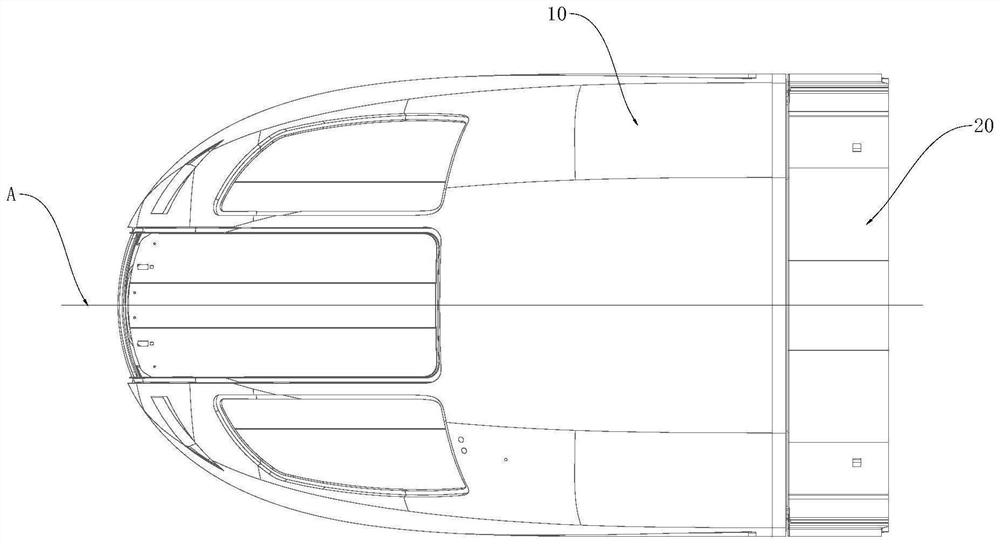

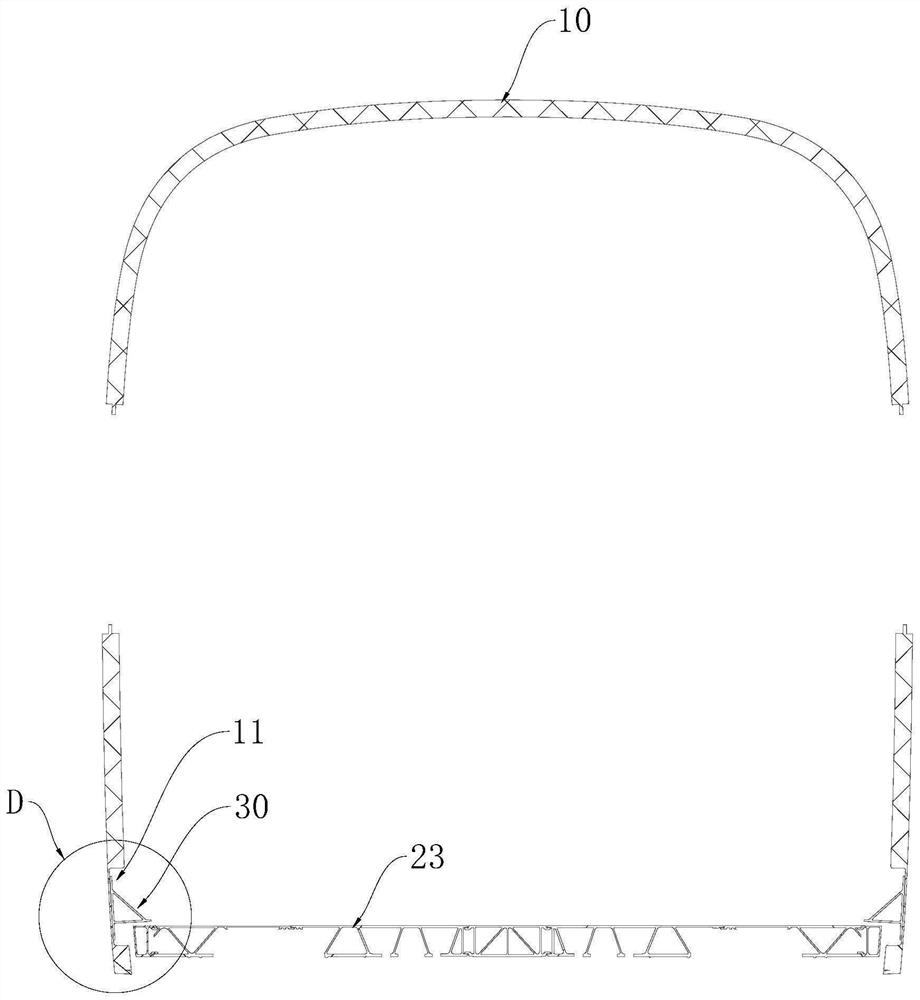

[0036] Specific embodiments of the present disclosure will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present disclosure, and are not intended to limit the present disclosure.

[0037] In this disclosure, unless stated to the contrary, the used orientation words such as "up, down, left, right, front, back" are generally the same as up, down, left, right, front, front, After means the same. Specifically, for a rail vehicle, along the length direction of the rail vehicle, the driver's cab head cover 10 is located at the front, and the vehicle body 20 is located at the rear. In addition, "inside and outside" refer to the inside and outside of the outline of the relevant parts.

[0038] Such as Figure 1 to Figure 8 As shown, the present disclosure provides a rail vehicle, which includes a driver's cab head cover 10 and a car body 20,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com