3D packaging film winding machine

A technology of packaging film and winding machine, which is applied in the direction of packaging, transportation packaging, transportation and packaging, etc., can solve problems such as complex structure, and achieve the effect of fast coating, compact structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

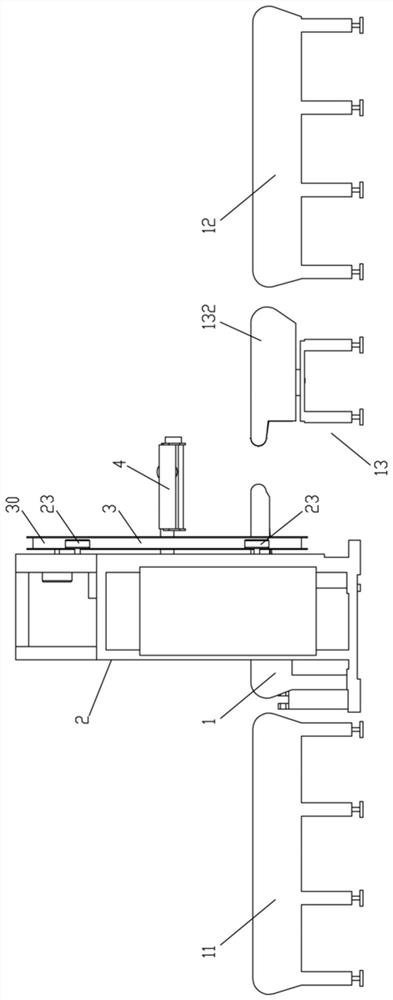

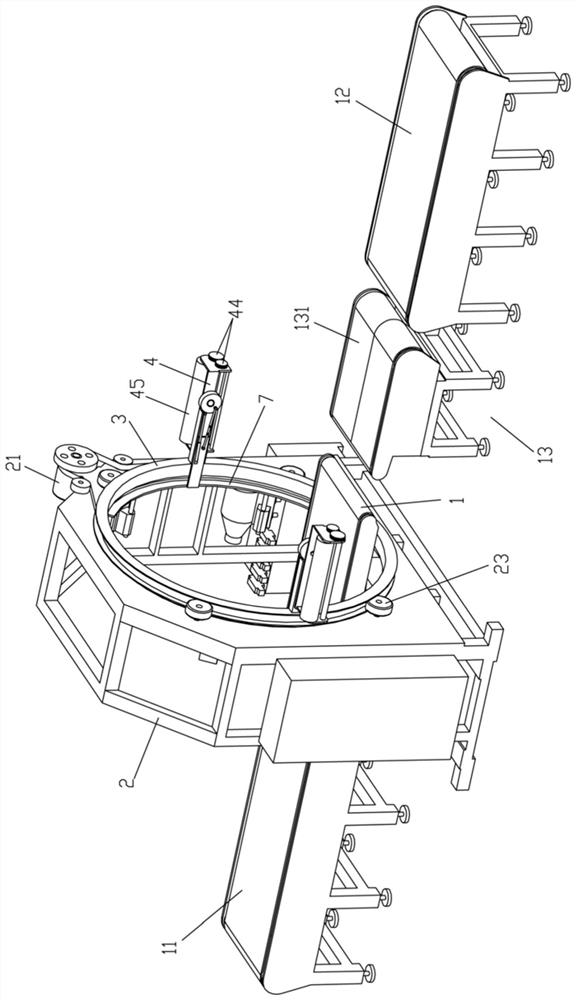

[0037] refer to Figure 1 to Figure 14 , a 3D packaging film winding machine, which includes a feeding device 11, a packaging film winding device, a rotary conveying device 13 and a sending device 12 arranged in sequence.

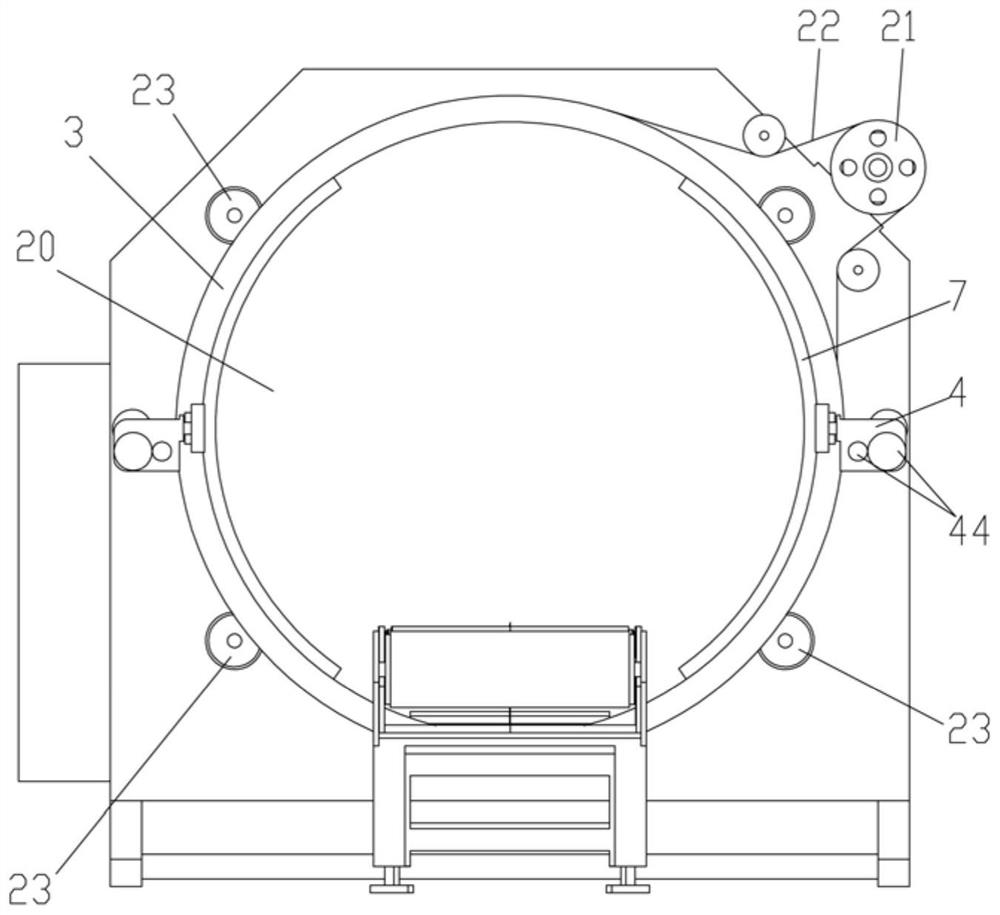

[0038] refer to Figure 2 to Figure 4 , the packaging film winding device includes a main frame 2, a main motor 21, a rotating frame belt 22 and a conveying device 1. The main frame 2 is a frame structure arranged vertically, and the middle part of the main frame 2 has a circular winding station cavity 20 . The rear side of the main frame 2 is provided with an annular rotating frame 3 movably corresponding to the edge of the winding station cavity 20 . The outer wall of the rotating frame 3 has a rotating frame clamping groove 30 coaxially arranged with the rotating frame 3 .

[0039] Four evenly distributed positioning rollers 23 are arranged on the rear side of the main frame 2 corresponding to the surroundings of the rotating frame 3 , and the edges of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com