Longitudinal sealing device of filling system

A sealing device and filling system technology, applied in packaging sealing/fastening, packaging, transport packaging, etc., can solve problems such as poor sealing accuracy, and achieve the effects of reliable sealing, convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

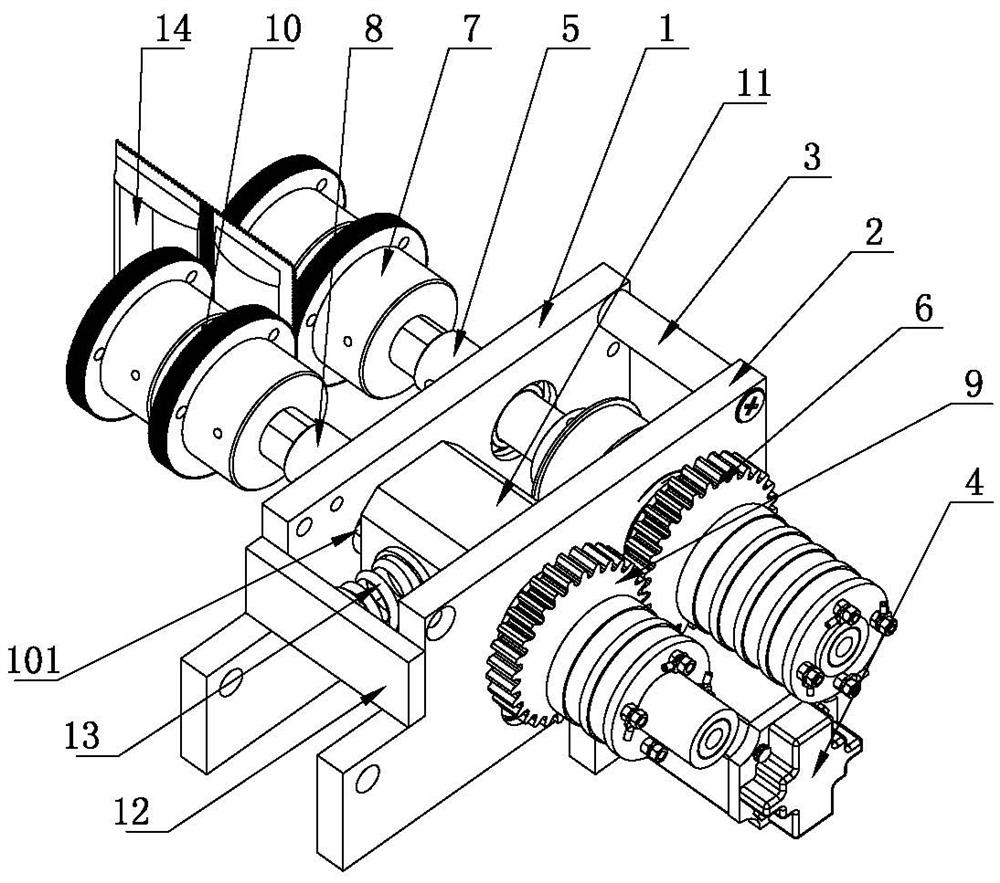

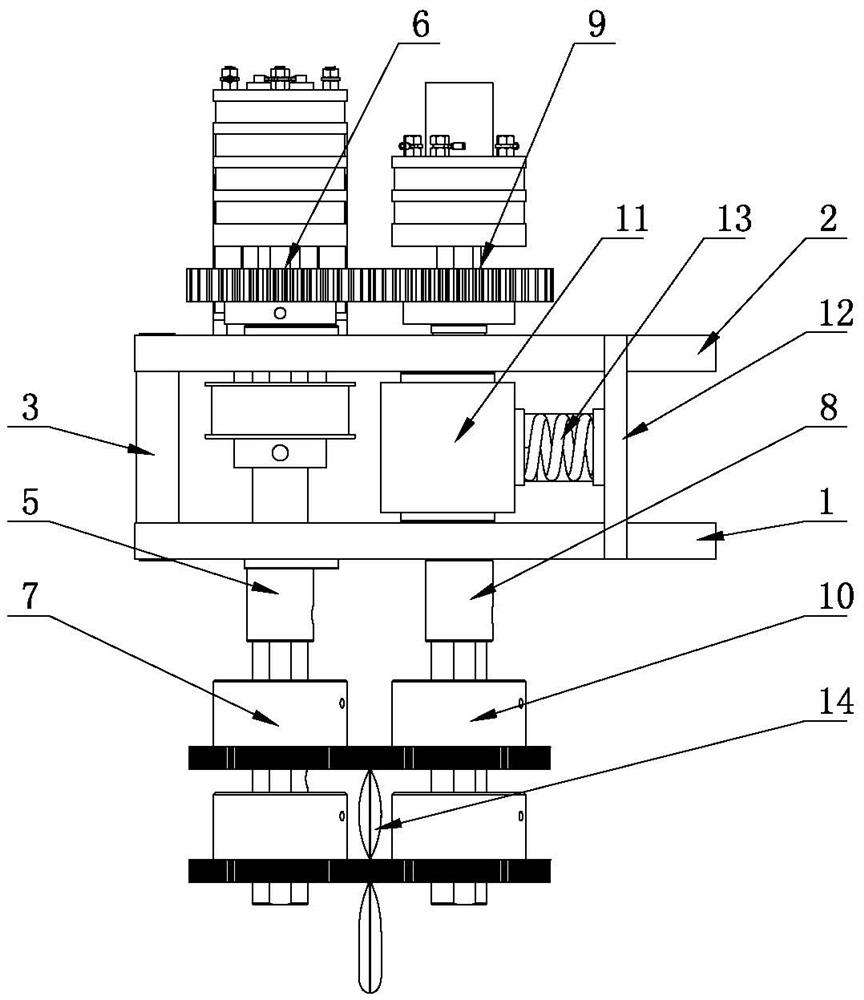

[0011] Such as Figure 1-2 The shown longitudinal sealing device of a filling system includes a pair of first mounting plate 1 and second mounting plate 2 connected together by a plurality of connecting rods 3, the first mounting plate 1 fixes the inner side of the side plate of the chassis 1, and the second The drive motor 4 is fixed on the two mounting plates 2, the output shaft of the drive motor 4 is inserted between the first mounting plate 1 and the second mounting plate 2, and the driving shaft 5 and the driven shaft 8 are arranged on the two mounting plates. The driving motor 4 drives the driving shaft 5 to rotate through the output shaft. The output shaft of the driving motor 4 is connected to the driving shaft 5. One end of a mounting plate 1 is provided with a first sealing pressure roller 7, and one end of the driven shaft 8 protruding from the second mounting plate 2 is provided with a driven gear 9, and the driven shaft 8 protrudes from one end of the first mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com