A method for arranging temperature measuring tubes and temperature control method for producing isostatic graphite in Acheson furnace

An Acheson furnace and isostatic pressing technology, applied in furnace control devices, chemical instruments and methods, furnaces, etc., can solve the problem that there is no introduction of related parties in the temperature measuring tube and temperature measuring method, and the furnace head and furnace tail are not equipped with measuring instruments. Temperature tube, which is not conducive to temperature monitoring and measurement, etc., to achieve the effect of strong uniformity in the furnace, effective temperature control, and stable power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

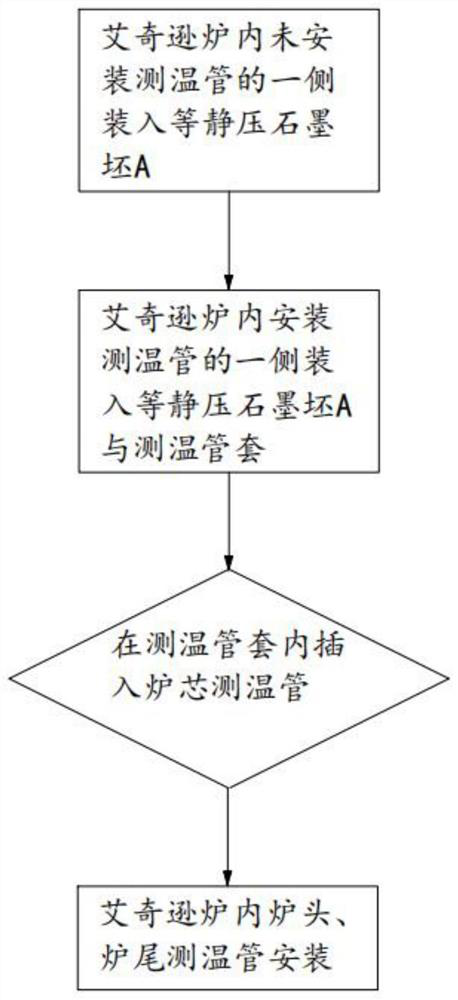

[0046] Such as Figure 1 to Figure 4 As shown, a method for arranging the temperature measuring tubes of an Acheson furnace to produce isostatic graphite comprises the following steps:

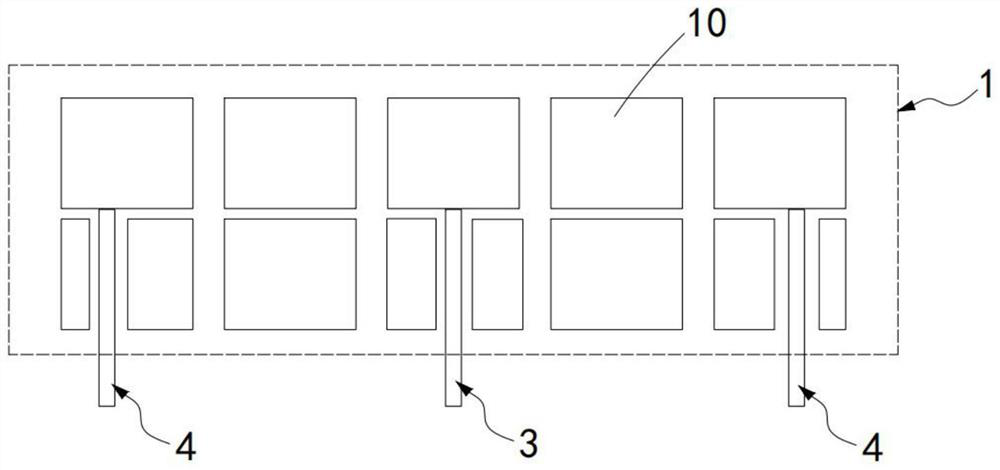

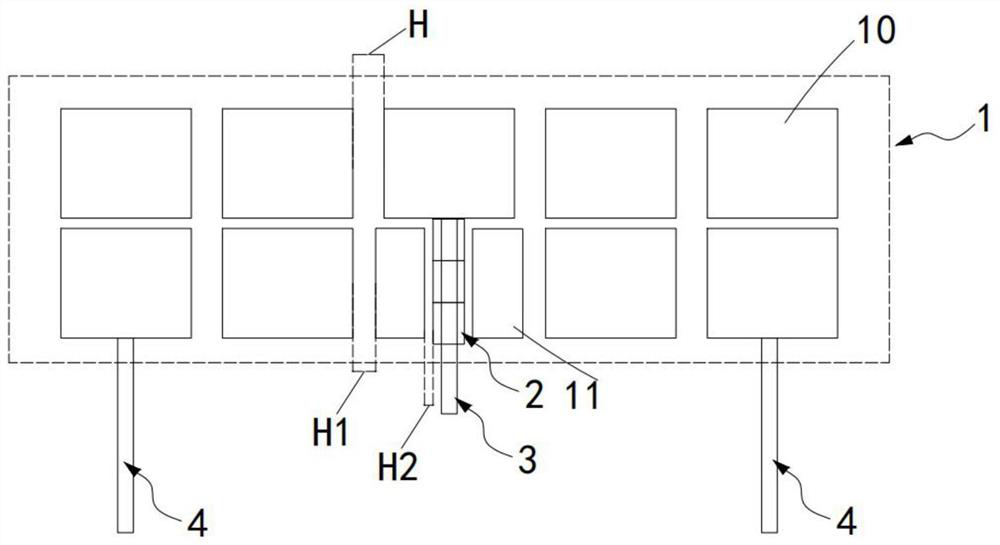

[0047] Step 1, one-time furnace loading, the isostatic graphite billet A10 to be processed is loaded into the Acheson furnace 1, and the isostatic graphite billet A10 is not installed on the side of the Acheson furnace 1 where the temperature measuring tube is installed. A10 is equidistantly arranged along the length direction of the Acheson furnace 1, and the spacing between adjacent isostatic graphite billets A10 is H;

[0048] Step 2, secondary furnace loading, install the side of the temperature measuring tube in the Acheson furnace 1, and load the equidistant arrangement of the distance H along the length direction of the Acheson furnace 1. The isostatic graphite blank A10, the spacing between the adjacent isostatic graphite blanks A10 is H, and the temperature measuring tube sleeve 2 is...

Embodiment 2

[0059] Figure 5 It is the schematic flow sheet of embodiment two of the temperature measuring tube arrangement method of producing isostatic graphite in a kind of Acheson furnace of the present invention; Figure 5 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. This embodiment two and figure 1 The difference of the shown embodiment one is:

[0060] Such as Figure 5 As shown, a method for arranging the temperature measuring tubes of an Acheson furnace to produce isostatic graphite, in the first step, the middle part of the length direction of the side of the Acheson furnace 1 that is not equipped with a temperature measuring tube is facing the When the position of the temperature measuring tube cover 2 is the isostatic graphite blank C12, the width o...

Embodiment 3

[0065] Figure 6 It is the schematic flow sheet of embodiment three of the temperature measuring tube arrangement method of producing isostatic graphite in a kind of Acheson furnace of the present invention; Figure 6 As shown, the parts that are the same as or corresponding to those in the third embodiment are marked with the corresponding reference numerals in the second embodiment. For the sake of simplicity, only the differences from the second embodiment are described below. This embodiment three and Figure 5 The differences of the shown embodiment two are:

[0066] Such as Figure 6 As shown, a method for arranging the temperature measuring tubes of an Acheson furnace to produce isostatic graphite, in the second step, the distance between the temperature measuring tube sleeve 2 and the adjacent isostatic graphite blank A10 is respectively On the side of H3, the distance between the isostatic graphite blank C12 and the adjacent isostatic graphite blank A10 on this sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com