Novel biological preservative film and preparation method thereof

A new type of biological fresh-keeping technology, applied in the field of new biological fresh-keeping film and its preparation, achieves the effects of convenient use, low comprehensive use cost and less material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

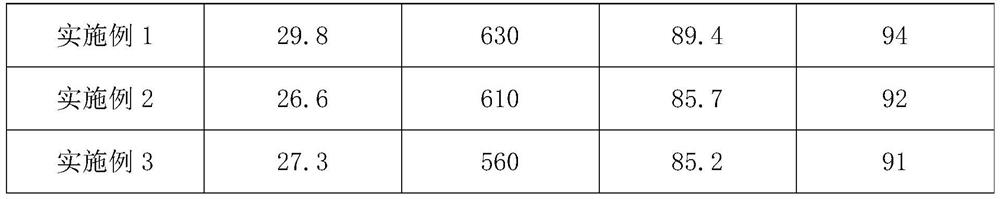

Embodiment 1

[0024] A new type of biological preservative film, made of the following components by weight: 65 parts of polylactic acid, 60 parts of biodegradable aliphatic-aromatic copolyester, 3 parts of toughening agent, 5 parts of chitosan, absorption 1 part of agent, 1 part of antibacterial oil, 0.5 part of antioxidant, 0.5 part of lubricant, dry polylactic acid and biodegradable aliphatic-aromatic copolyester in an oven at 75-80 ° C for 4-5 hours, and make each component Moisture content ≤ 0.08%, and then polylactic acid, biodegradable aliphatic-aromatic copolyester, toughener, chitosan, absorbent, antibacterial oil, antioxidant, lubricant of each component are added to the high-mixing In the machine, mix at a high speed at room temperature for 5-10 minutes; feed the blend in the high-speed mixer into the screw extruder through the feeding port, and then blow it into a film and cool it down to obtain the fresh-keeping film.

Embodiment 2

[0026] A new type of biological preservative film, made of the following components by weight: 80 parts of polylactic acid, 60 parts of biodegradable aliphatic-aromatic copolyester, 4 parts of toughening agent, 2 parts of chitosan, absorption 1 part of agent, 4 parts of antibacterial oil, 0.3 part of antioxidant, 0.4 part of lubricant. Dry the polylactic acid and biodegradable aliphatic-aromatic copolyester in an oven at 75-80°C for 4-5h to make the moisture content of each component ≤0.08%, and then dry the polylactic acid and biodegradable aliphatic copolyester of each component - Aromatic copolyester, toughening agent, chitosan, absorbent, antibacterial oil, antioxidant, and lubricant are added to the high-speed mixer, and mixed at high speed for 5-10 minutes at room temperature; the blend in the high-mixer It is fed into a screw extruder through a feeding port, blown into a film and then cooled to obtain the fresh-keeping film.

Embodiment 3

[0028] A new type of biological preservative film, made of the following components by weight: 50 parts of polylactic acid, 70 parts of biodegradable aliphatic-aromatic copolyester, 3 parts of toughening agent, 3 parts of chitosan, absorption 2 parts of agent, 3 parts of antibacterial oil, 0.4 part of antioxidant, 0.3 part of lubricant. Dry the polylactic acid and biodegradable aliphatic-aromatic copolyester in an oven at 75-80°C for 4-5h to make the moisture content of each component ≤0.08%, and then dry the polylactic acid and biodegradable aliphatic copolyester of each component - Aromatic copolyester, toughening agent, chitosan, absorbent, antibacterial oil, antioxidant, and lubricant are added to the high-speed mixer, and mixed at high speed for 5-10 minutes at room temperature; the blend in the high-mixer It is fed into a screw extruder through a feeding port, blown into a film and then cooled to obtain the fresh-keeping film.

[0029] experiment one:

[0030] The fres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com