Multicolor light-resistant composite rock slice, preparation method thereof and flexible coiled material

A composite rock chip and light-resistant technology, applied in the field of building materials, to achieve a high degree of simulation and overcome the effect of single color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

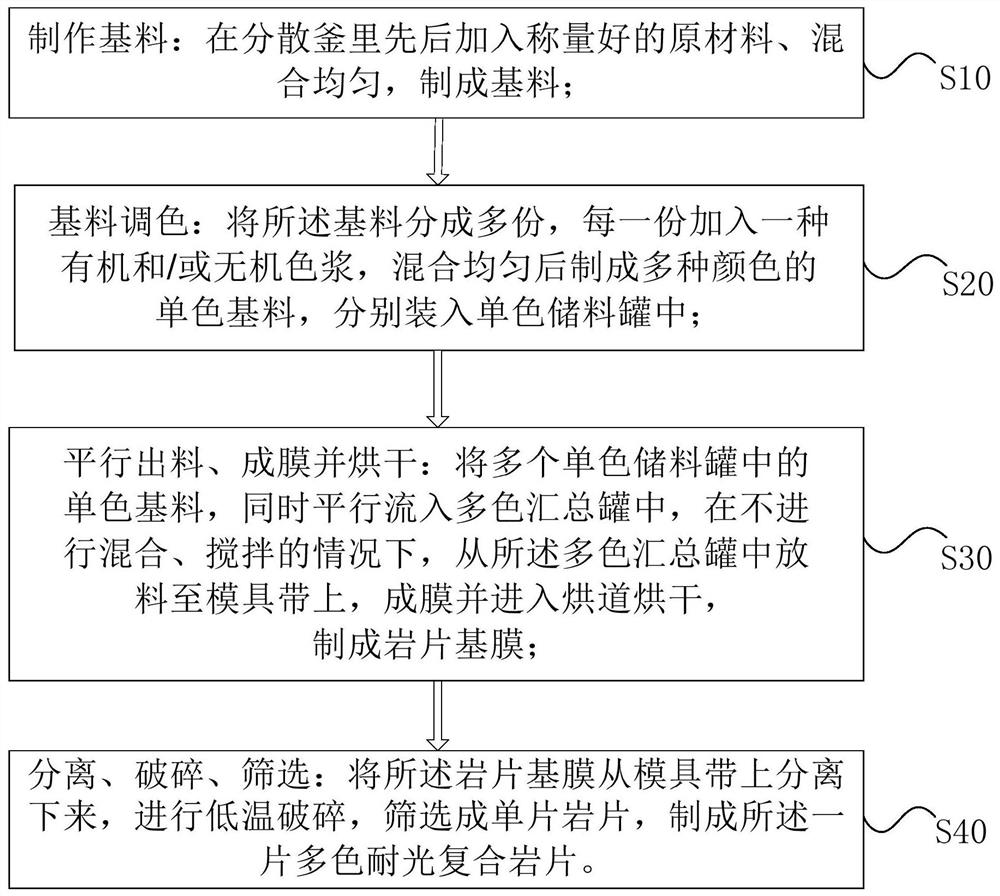

[0024] Some embodiments of the present invention, such asfigure 1 As shown, a kind of preparation method of multi-color light-resistant composite rock slice is provided, comprising the following steps:

[0025] S10, making the base material: add the weighed raw materials into the dispersing kettle successively, mix them evenly, and make the base material;

[0026] S20, base material color matching: according to the set requirements, the base material is divided into multiple parts, each part is added with an organic and / or inorganic color paste, mixed evenly to make a single-color base material of various colors, Put them into the monochrome storage tank respectively;

[0027] S30, discharging in parallel, forming a film and drying: the single-color base material in multiple single-color storage tanks flows into the multi-color collection tank in parallel at the same time, without mixing or stirring, from the multiple The material is discharged from the color collection tank ...

Embodiment 1

[0040] 1. Make the base material:

[0041] A water: 6 parts

[0042] B Blj-838A-2 styrene-acrylic emulsion: 27 parts

[0043] C Coalescing agent Dow Alcohol Ester-12: 1.1 parts

[0044] D plasticizer dimethyl phthalate: 1.2 parts

[0045] E defoamer CF-245: 0.2 parts

[0046] F dispersant 5040: 0.5 parts

[0047] G PH regulator AMP-95: 0.3 parts

[0048] H UV absorber Richter: 0.2 parts

[0049] I light stabilizer Jing Tianwei BT4: 0.2 parts

[0050] J filler 1 kaolin (1250 mesh): 5 parts

[0051] K filler 2 heavy calcium carbonate (325 mesh): 58 parts

[0052] L thickener TT-935: 0.3 parts

[0053] Inject the weighed A and B into the dispersing tank first, start stirring at a speed of 300r / min, then slowly add C, D, E, F, G, H, I and stir for 10 minutes, and then increase the speed to 800r / min Slowly add J and K in turn, disperse for 20 minutes, slowly add L, and stir for 5 minutes to prepare the base material.

[0054] 2. Coloring of the base material:

[0055] D...

Embodiment 2

[0059] The formulation of the base material is:

[0060] Water: 3.9 parts

[0061] Blj-838A-2 styrene-acrylic emulsion: 29 parts

[0062] Coalescing agent Dow Alcohol Ester-12: 1.2 parts

[0063] Plasticizer dimethyl phthalate: 1.2 parts

[0064] Defoamer CF-245: 0.2 parts

[0065]Dispersant 5040: 0.5 parts

[0066] PH regulator AMP-95: 0.3 parts

[0067] Ultraviolet light absorber Richter: 0.2 parts

[0068] Light stabilizer Jingtianwei BT4: 0.2 parts

[0069] Filler 1 kaolin (1250 mesh): 5 parts

[0070] Filler 2 heavy calcium carbonate (325 mesh): 58 parts

[0071] Thickener TT-935: 0.3 parts

[0072] The method steps of this embodiment 2 to prepare a multi-color light-resistant composite rock slice are basically the same as the above-mentioned embodiment 1, the difference is that 6 monochrome storage tanks are used, and the discharge ports of the 6 monochrome storage tanks are arranged in a Two rows, every 3 is a row, and the two rows are close to each other; and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com