Preparation method of a large-area superhydrophobic coating with adjustable liquid adhesion

A technology of super-hydrophobic coating and adhesion, which is applied in coatings, epoxy resin coatings, etc., and can solve the problems of high cost, cumbersome process, and inapplicability of large-area super-hydrophobic coatings with adjustable liquid adhesion. , to achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

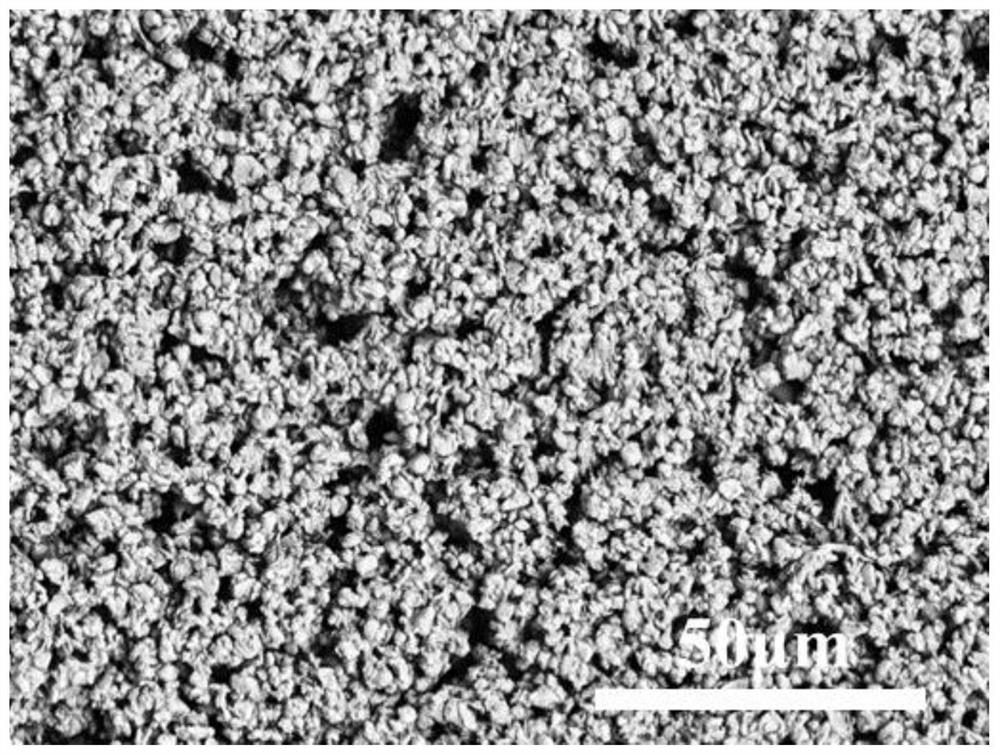

[0031] Specific embodiment one: a kind of preparation method of the large-area superhydrophobic coating that can control the liquid adhesion of this embodiment is carried out according to the following steps:

[0032] 1. Dissolve 10g of polytetrafluoroethylene particles in 40mL of acetone, and magnetically stir for 20 minutes until the mixture is uniform to obtain a polytetrafluoroethylene solution;

[0033] 2. Dissolve 4g of epoxy resin in 8mL of acetone and stir until the epoxy resin is completely dissolved to obtain an epoxy resin solution;

[0034] 3. Mix the polytetrafluoroethylene solution and the epoxy resin solution to obtain a PTFE / epoxy resin mixture, and then add 1H, 1H, 2H, 2H-perfluorodecyltrimethoxy to the PTFE / epoxy resin mixture dropwise base silane, then added triethylenetetramine, first magnetically stirred for 20min, then ultrasonically treated for 20min, and then magnetically stirred for 20min to obtain a superhydrophobic coating solution; in the PTFE / epoxy...

specific Embodiment approach 2

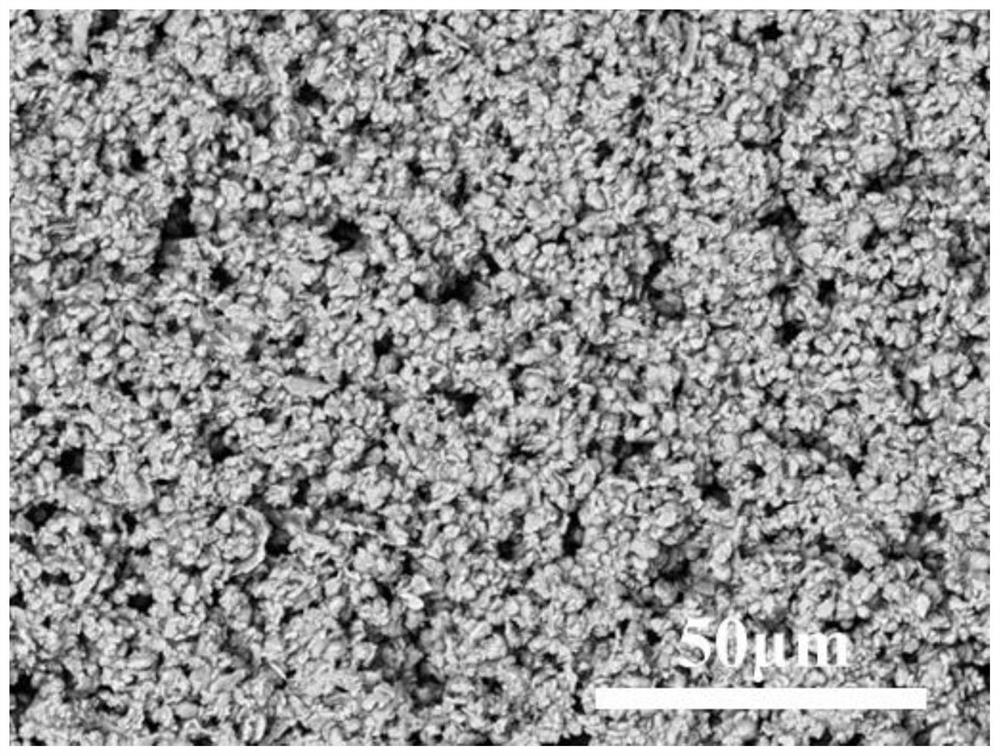

[0036] Embodiment 2: This embodiment differs from Embodiment 1 in that the spraying pressure in step 4 is 0.25 bar. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

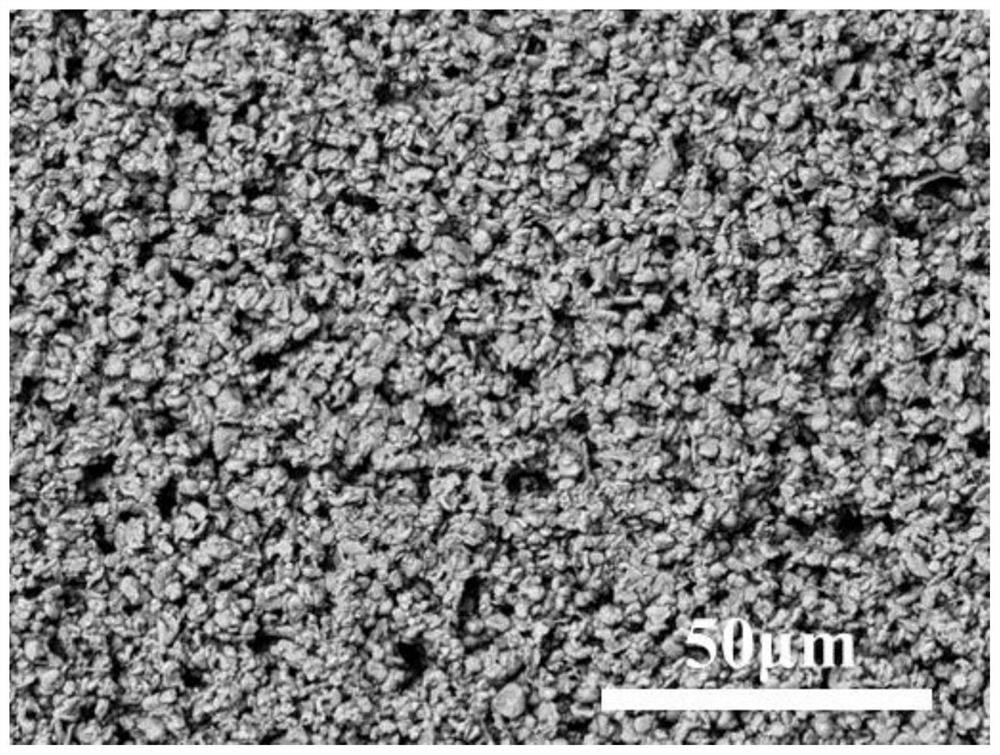

[0037] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the spraying pressure in step 4 is 0.5 bar. Other steps and parameters are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com