Controllable perfuming self-adhesive microcapsule for textiles as well as preparation and application of controllable perfuming self-adhesive microcapsule

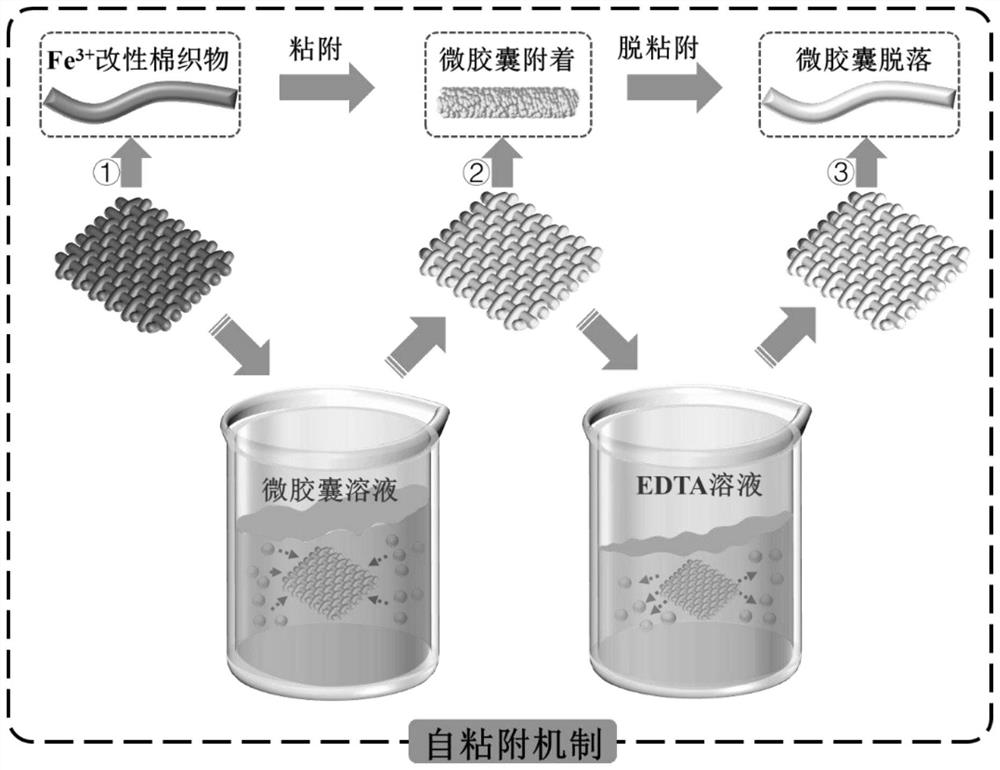

A technology of microcapsules and textiles, applied in the field of aromatic textile materials, can solve the problems of short fragrance retention time, weak binding ability between microcapsules and textiles, irreversible one-way between microcapsules and textiles, etc., and achieves the effect of strong bonding and firmness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] A method of preparing controllable adhesion microcapsules for textiles, comprising the steps of:

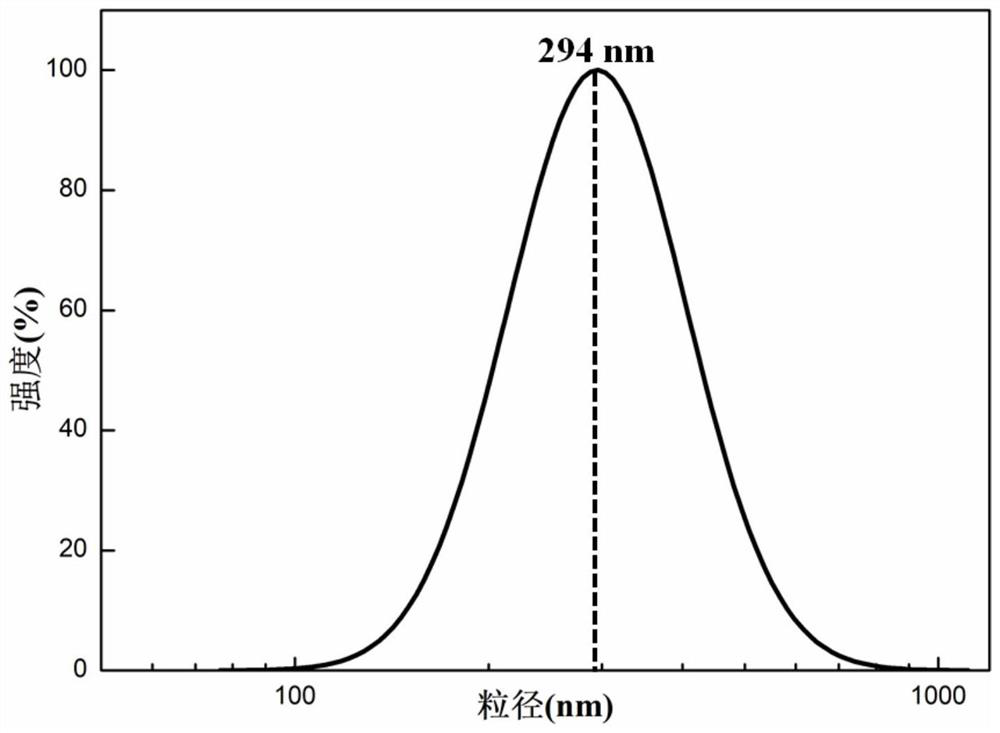

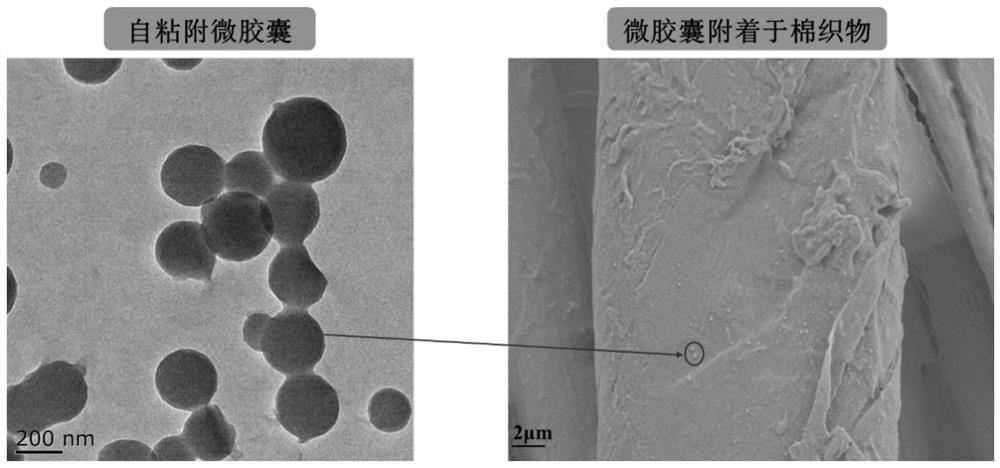

[0064] (1) Weigh 2.0g of water-soluble chitosan, and dissolve it in 100g of deionized water, add 1.0g of Tween 80 and 2.0g of Hemerocallis essence after it is fully dissolved; then ultrasonically disperse at 250W for 20min, to obtain a mixed solution;

[0065] Weigh 0.24g of sodium tripolyphosphate and dissolve it in 10mL of water, then add it dropwise (with a dropping rate of 0.33mL / min) into the mixed solution, and react at 25°C and 1000rpm for 120min to obtain the essence / chitosan microparticles. capsule solution;

[0066] (2) Weigh 2.0g of carboxymethyl β-cyclodextrin and 20g of water, and after dissolving them; and 1.8g of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and 1.1g of N-hydroxysuccinimide was mixed, and reacted at 25°C and 300rpm for 35min to obtain a mixed solution;

[0067] (3) Drop 20 mL of the mixed solution of step (2) into 115 mL of ...

Embodiment 2

[0070] A method of preparing controllable adhesion microcapsules for textiles, comprising the steps of:

[0071] (1) Weigh 2.0g water-soluble chitosan, dissolve it in 100g deionized water, add 1.2g of Tween 80 and 1.8g of jasmine essence after it is fully dissolved; then ultrasonically disperse at 300W for 15min, to obtain a mixed solution;

[0072] Weigh 0.4g of sodium tripolyphosphate and dissolve it in 20mL of water, then add it dropwise (the rate of addition is 0.5mL / min) into the mixed solution, and react for 80min under the condition of 800rpm to obtain the essence / chitosan microcapsule solution;

[0073] (2) Weigh 2.0g of carboxymethyl β-cyclodextrin and 20g of water, and after dissolving them; and 1.8g of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and 1.1g of N-hydroxysuccinimide was mixed, and reacted at 25°C and 300rpm for 50min to obtain a mixed solution;

[0074] (3) Drop 24 mL of the mixed solution of step (2) into 105 mL of the essence / chitosan...

Embodiment 3

[0076] A method of preparing controllable adhesion microcapsules for textiles, comprising the steps of:

[0077] (1) take by weighing 3.0g water-soluble chitosan, and dissolve it in 100g deionized water, after it is fully dissolved, add 1.5g of Tween 80 and 3g jasmine essence respectively; Then in 200W ultrasonic dispersion 20min, obtain mixture;

[0078] Weigh 0.35g of sodium tripolyphosphate and dissolve it in 18mL) water, then add it dropwise (the rate of addition is 0.5mL / min) into the mixed solution, and react for 100min under 700rpm conditions to obtain essence / chitosan microcapsule solution ;

[0079] (2) Weigh 2.0g of carboxymethyl β-cyclodextrin and 20g of water, and after dissolving them; and 1.8g of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride and 1.1g of N-hydroxysuccinimide was mixed, and reacted at 25°C and 400rpm for 45min to obtain a mixed solution;

[0080] (3) Drop 25 mL of the mixed solution of step (2) into 107 mL of the essence / chitosan m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com