Manufacturing process of polyamide 6 with high-strength structure

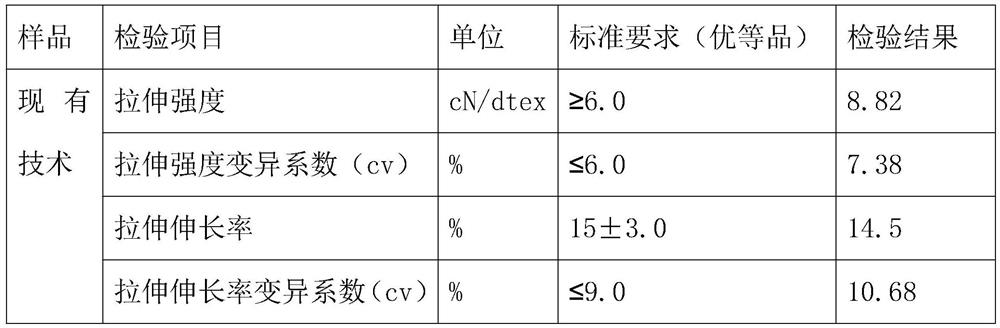

A manufacturing process, polyamide technology, applied in the field of high-strength fibers, can solve the problems of coefficient of variation of strength, coefficient of variation of tensile elongation not meeting the standard requirements, poor quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment one: a kind of manufacturing process of high-strength structural polyamide 6, it comprises the following steps:

[0028] 1. Feeding stage: Add PA6 spinning raw material into the screw extruder, and the relative viscosity of the raw material is 2.65;

[0029] 2. Melting stage: After the PA6 spinning raw material enters the screw extruder, it melts under the high temperature environment of the screw extruder, and is further mixed evenly under the stirring of the screw. The temperature of the screw temperature zone is set to 255 degrees, and the temperature of biphenyl is 270 degrees;

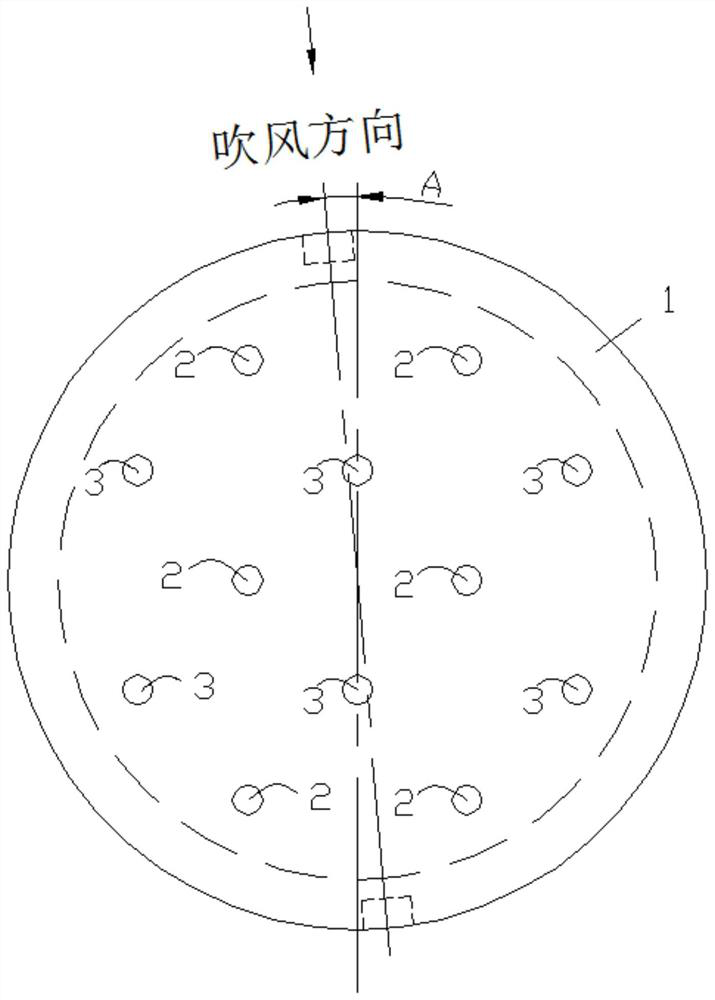

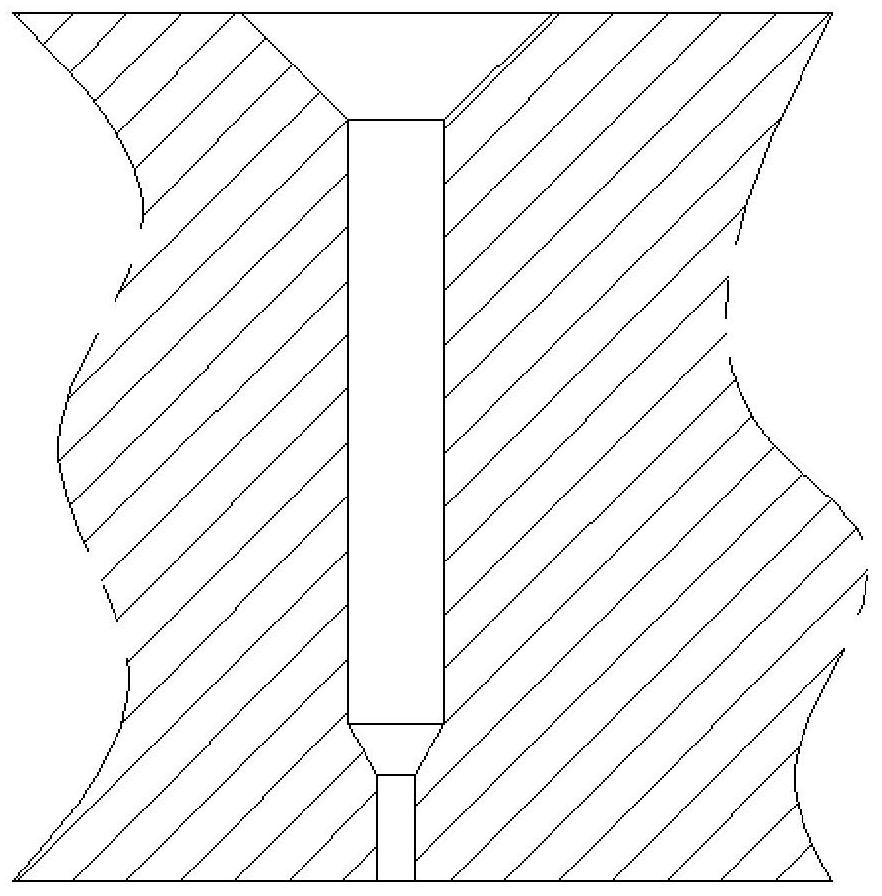

[0030] 3. Spinning stage: After the melt is melted and mixed evenly by the screw, it enters the spinning box, and is sprayed out through the spinning assembly and spinneret 1 to form PA6 primary filament bundles. The spinning assembly uses a newly designed and processed spinneret 1 Assembly, the pressure of the spinning assembly is adjusted to 13.0Mpa, the spinneret is provided ...

Embodiment 2

[0036] Embodiment two: a kind of manufacturing process of high-strength structural polyamide 6, it comprises the following steps:

[0037] 1. Feeding stage: Add PA6 spinning raw material into the screw extruder, and the relative viscosity of the raw material is 3.01;

[0038] 2. Melting stage: After the PA6 spinning raw material enters the screw extruder, it melts in the high temperature environment of the screw extruder, and is further mixed evenly under the agitation of the screw. The temperature of the screw temperature zone is set to 260 degrees, and the biphenyl temperature is 275 degrees;

[0039] 3. Spinning stage: After the melt is melted and mixed evenly by the screw, it enters the spinning box, and is sprayed out through the spinning assembly and spinneret to form PA6 primary filament bundles, and the spinning assembly is assembled with a newly designed and processed spinneret , the spinning assembly pressure is adjusted to 15.0Mpa, the spinneret is provided with mult...

Embodiment 3

[0045] Embodiment three: a kind of manufacturing process of high-strength structural polyamide 6, it comprises the following steps:

[0046] 1. Feeding stage: Add PA6 spinning raw material into the screw extruder, and the relative viscosity of the raw material is 3.15;

[0047] 2. Melting stage: After the PA6 spinning raw material enters the screw extruder, it melts in the high temperature environment of the screw extruder, and is further mixed evenly under the stirring of the screw. The temperature of the screw temperature zone is set to 280 degrees, and the temperature of biphenyl is 280 degrees;

[0048] 3. Spinning stage: After the melt is melted and mixed evenly by the screw, it enters the spinning box, and is sprayed out through the spinning assembly and spinneret to form PA6 primary filament bundles, and the spinning assembly is assembled with a newly designed and processed spinneret , the spinning assembly pressure is adjusted to 18.0Mpa, the spinneret is provided wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com