Narrow-frame LED panel lamp

A technology of LED panel light and narrow frame, which is applied in the direction of lighting auxiliary devices, lighting and heating equipment, fixed lighting devices, etc. It can solve the problem of poor uniformity of light in the center of the light-emitting panel, increased difficulty in light distribution and splicing, and poor visual effects, etc. problem, to achieve the effect of reducing the width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

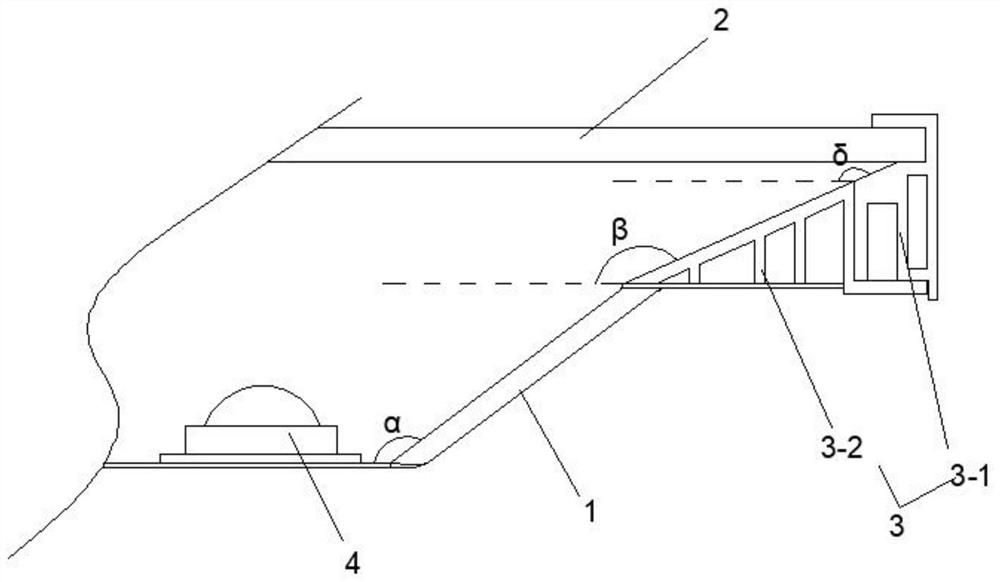

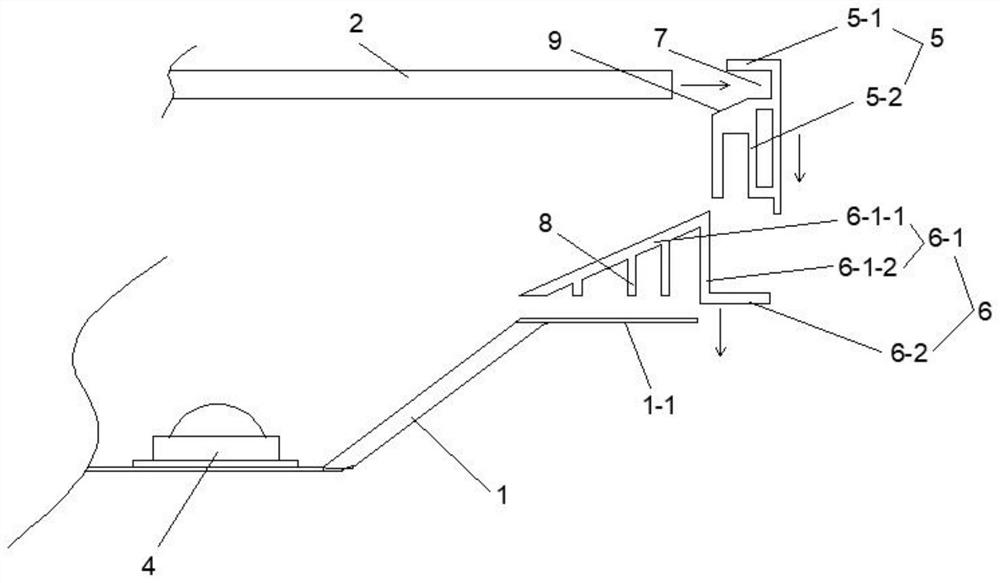

[0020] Such as figure 1 , figure 2 As shown, this embodiment includes a chassis 1, a light-emitting panel 2, and a fixed frame 3, wherein the fixed frame 3 includes a surrounding edge 5-1 arranged outside the light-emitting panel 2, and the width of the surrounding edge 5-1 is less than or equal to 6 mm , this embodiment is preferably implemented with a size less than or equal to 5 mm. In the prior art, the width of the surrounding edge 5-1 is generally set within a size range of 20±1 mm. There are at least two bar-shaped light source groups 4 arranged in parallel on the chassis 1. The number of bar-shaped light source groups 4 is determined according to the specifications of the lamps. The number is at least two, and they are fixedly connected to the chassis 1 through screws. A heat-conducting silicone grease layer is arranged between the plate body and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com