Three-dimensional measurement method of weld seam surface after welding based on laser grating projection

A technology of three-dimensional measurement and weld surface, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of large inspection workload, the influence of contact wear of inspection results, and only qualitative analysis, and achieve three-dimensional precision measurement. , The system is simple and compact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below through specific examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

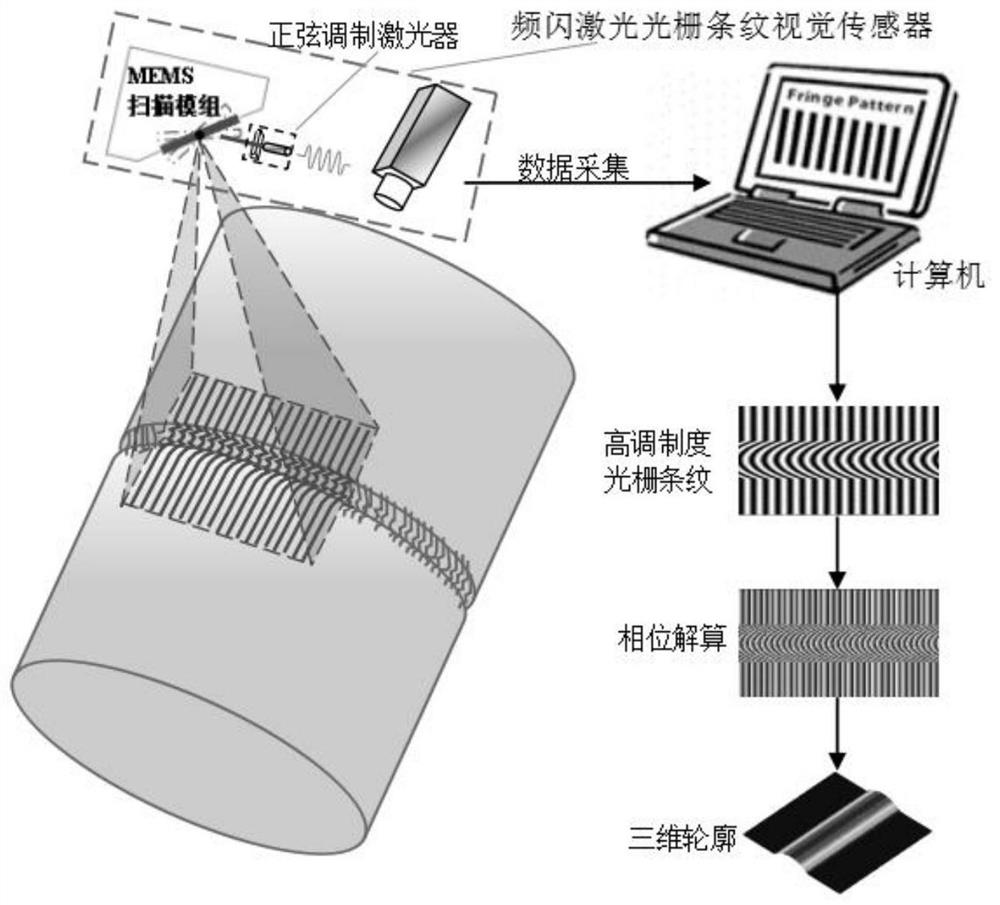

[0040] according to figure 1 A 3D welding seam measurement system based on stroboscopic laser grating stripes is built. build as image 3 The shown space maps the 3D measurement model and realizes the system calibration. Through the established model and calibration results, the phase information of the fringe image is accurately converted into the real 3D data of the weld, and the 3D measurement of the weld after welding is realized. write figure 2 The system software shown is used to collect and display weld images and weld image processing results. The design is completed and a deep fringe enhanced convolutional neural network for filtering the background light intensity of grating fringes and generating high-modulation grating fringes is complete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com