Stator core, stator assembly, motor, food processor and air supply device

A stator core and stator assembly technology, applied in electromechanical devices, pump devices, machines/engines, etc., can solve the problems of large magnetic flux leakage and loss, and achieve reduced magnetic loss, reduced magnetic resistance, and short magnetic circuits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

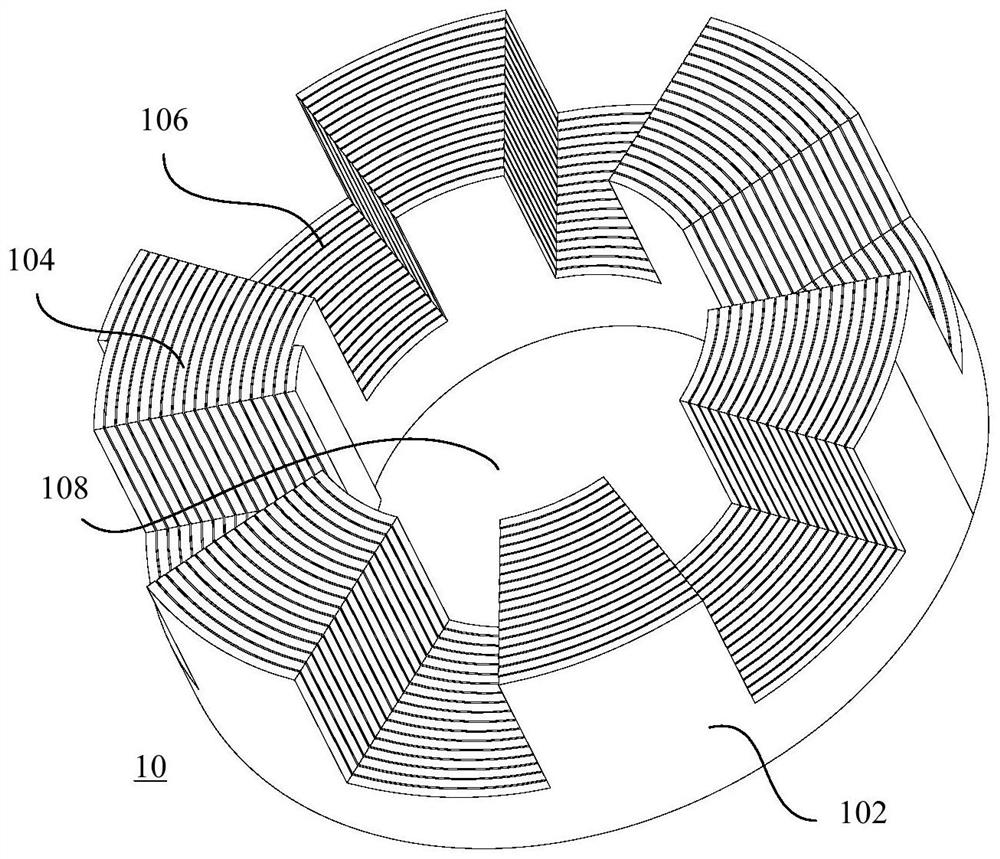

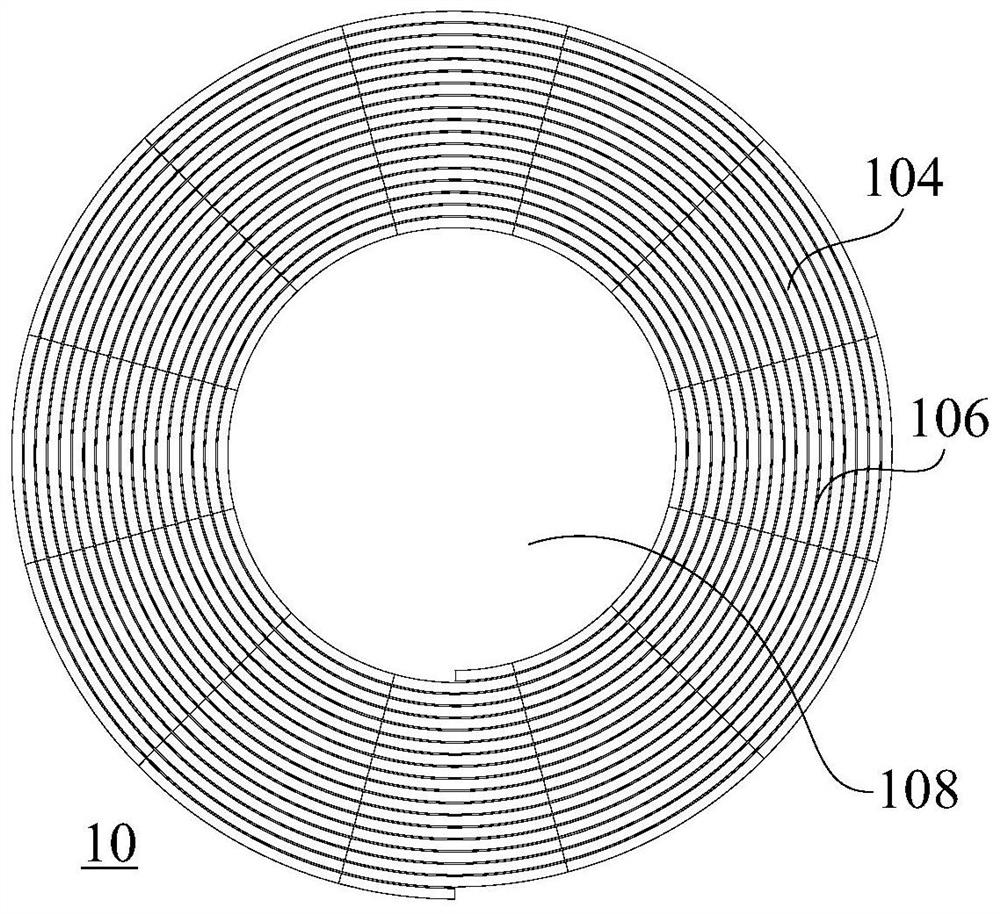

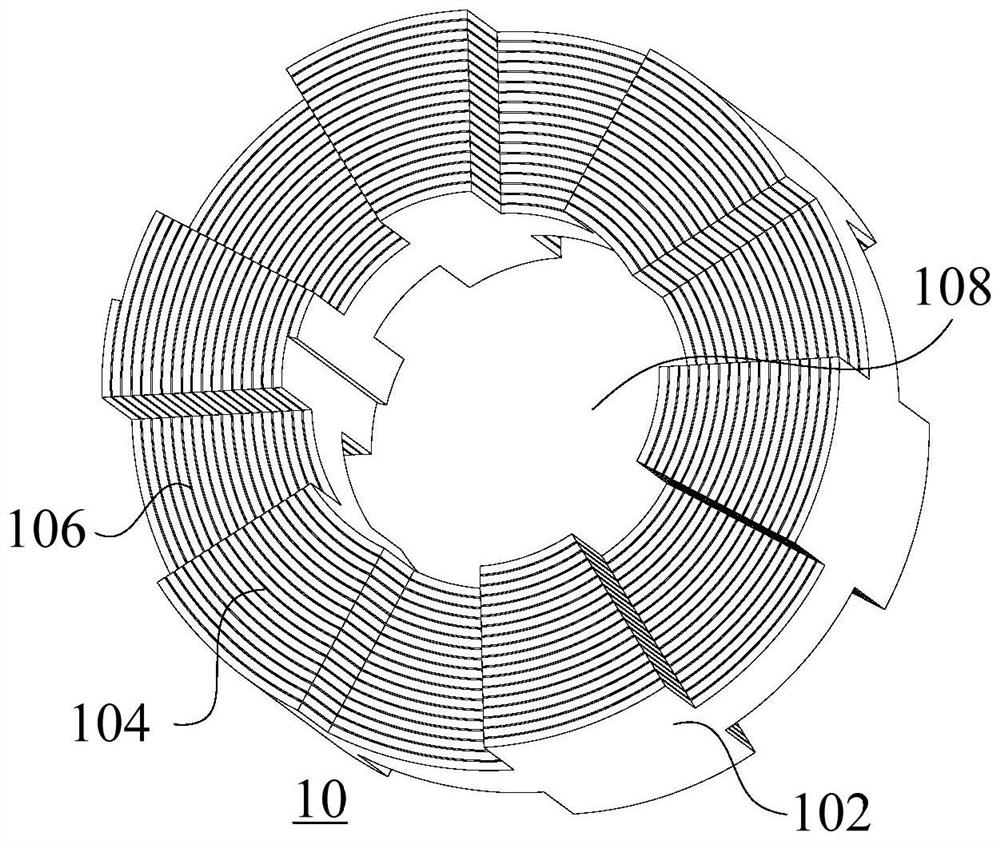

[0074] Such as figure 1 with figure 2 As shown, the first embodiment of the present invention proposes a stator core 10, the stator core 10 includes a multi-layer punching sheet 102, the multi-layer punching sheet 102 surrounds a central through hole 108, and the multi-layer punching sheet 102 The radial direction of the central through hole 108 is distributed in layers.

[0075] Specifically, during the use of the stator core 10, the magnetic field lines pass through the stator core 10 from the radial direction of the stator core 10, and the stator core 10 proposed by the present invention has the same extension direction as the multi-layer punching piece 102 The passing directions of the magnetic flux lines are the same, which can effectively reduce the reluctance of the stator core 10 , reduce the magnetic loss, and further improve the efficiency of the motor 100 . Specifically, the stator core 10 has a hollow cylindrical structure as a whole, and a central through hole ...

Embodiment 2

[0078] Such as figure 1 with figure 2 As shown, the first embodiment of the present invention proposes a stator core 10, the stator core 10 is composed of a punching piece 102 rolled from inside to outside along a helical line.

[0079] In this embodiment, considering the difficulty of manufacturing the stator core 10 , the multi-layer punching sheet 102 is formed by stacking one punching sheet 102 from inside to outside along a helical line. That is to say, in the process of manufacturing the stator core 10 , the final stator core 10 can be obtained by convolving a punching sheet 102 , and the manufacturing process is simple to reduce the cost of the stator core 10 . Specifically, the stator core 10 has a radial rolling structure, and the stator core 10 is formed by spirally rolling a strip-shaped punching sheet, and the punching sheet 102 can be a strip-shaped iron sheet.

Embodiment 3

[0081] Such as Figure 4 to Figure 8 As shown, the third embodiment of the present invention proposes a stator assembly 20, including: an insulating part, a plurality of stator windings 212, and the stator core 10 according to any one of the first aspect of the present invention, wherein the insulating part The stator core 10 is set on the insulating support 202 , and the support base 204 of the insulating support 202 is provided with an opening 206 , an escape notch 208 and a winding support 210 .

[0082] Specifically, such as Figure 6 to Figure 8 As shown, the opening 206 ensures that the rotating shaft 406 can smoothly pass through the support base 204; the stator core 10 extends into the support base 204 from the avoidance gap 208, so that the stator teeth 104 of the stator core 10 extend into the inside of the winding support 210, and the stator iron core The chassis of the core 10 is arranged corresponding to the support base 204 . By optimizing the structure of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com