VOC waste gas treatment device for environmental protection equipment

A technology of waste gas treatment device and environmental protection equipment, applied in gas treatment, transportation and packaging, cleaning methods and utensils, etc., can solve the problems of no impurity filtration and removal, and the waste gas treatment effect is not good enough, and achieve the effect of easy replacement and efficient treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

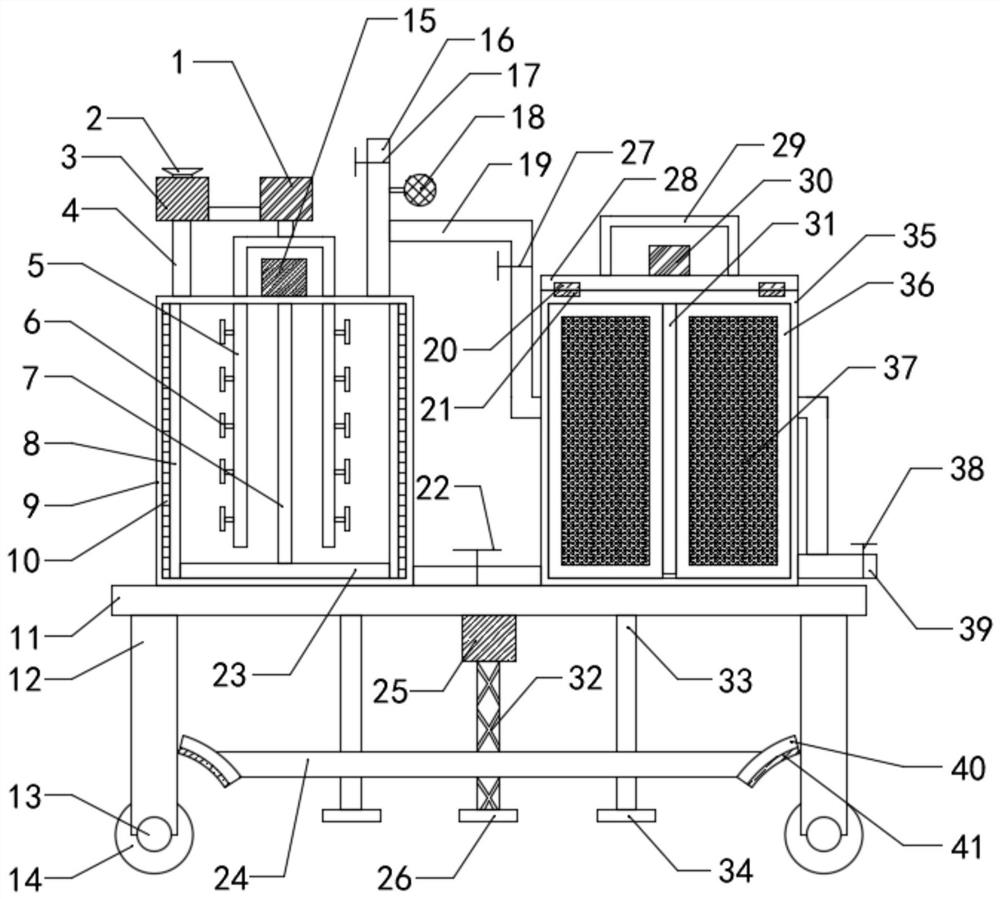

[0019]SeeFigure 1~2In an embodiment of the present invention, a VOC exhaust gas treatment device for environmental protection equipment includes a support base 11, the lower end of the support base 11 is connected to four support legs 12, and the lower end of the support leg 12 passes through a shaft 13 Connected to the moving wheel 14, the VOC exhaust gas treatment device for environmental protection equipment is moved through the moving wheel 14. The upper end of the supporting base plate 11 is provided with a purification mechanism one, and the supporting base plate 11 is also provided with a purification mechanism two. The cooperation of the first mechanism and the second purification mechanism purifies the exhaust gas.

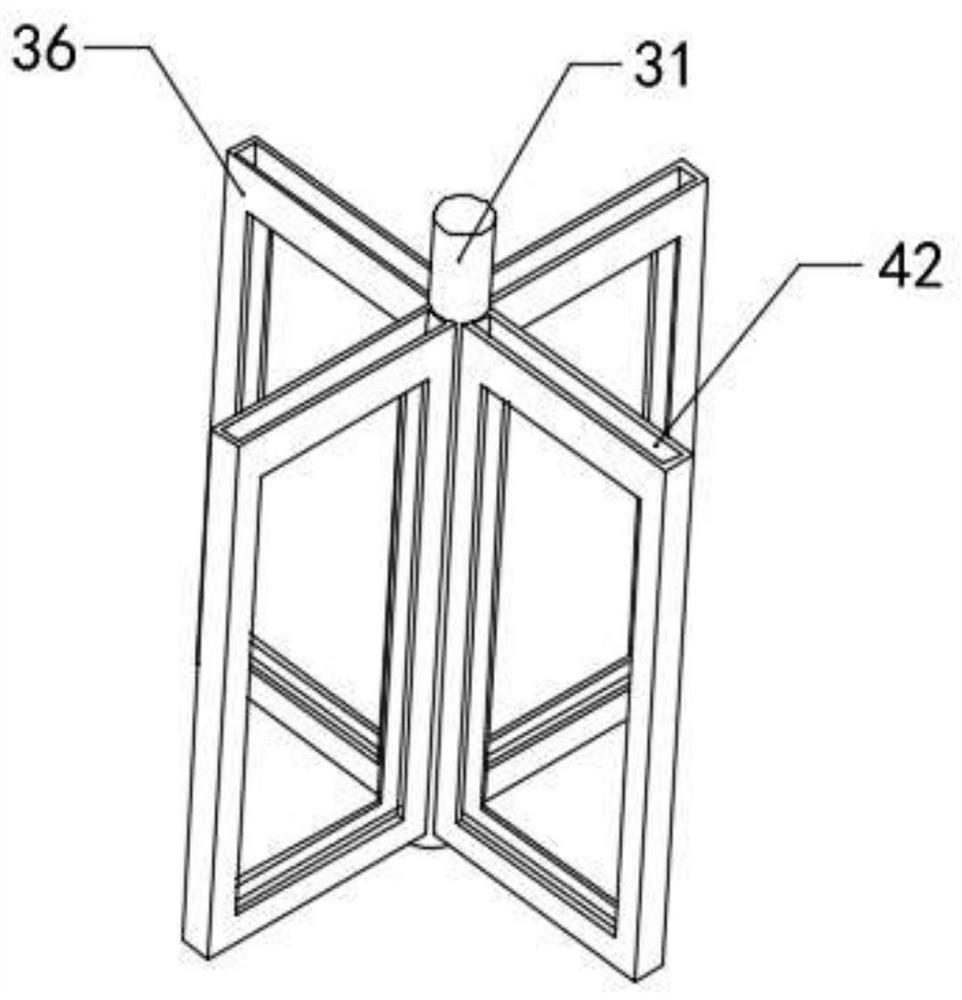

[0020]The specific form of the purification mechanism 1 is not limited. In this embodiment, preferably, the purification mechanism 1 includes a purification main body 35 connected to the supporting bottom plate 11, and the purification main body 35 is provided wit...

Embodiment 2

[0025]This embodiment is improved on the basis of embodiment 1. The lower end of the support base plate 11 is connected with a limit motor 25, and the rotating part of the limit motor 25 is connected with a reciprocating screw 32. The lower end is connected to a limit plate 26, and also includes a limit main plate 24 sleeved on the outside of the reciprocating screw 32, and also includes four limit rods 33 connected to the support base plate 11 symmetrically arranged in pairs. The lower end of the rod 33 is connected with the second limiting plate 34, the limiting rod 33 passes through the limiting main plate 24, and the side of the limiting main plate 24 is provided with four limiting curved plates 40 one-to-one corresponding to the moving wheels 14 , The lower end of the limiting curved plate 40 is provided with a limiting pad 41, the rotation of the limiting motor 25 drives the reciprocating screw 32 to rotate, so that the limiting main plate 24 moves up and down on the reciproca...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap