Automatic grinding device for cutter edging grinding wheel

A technology for grinding wheels and cutting tools, which is applied in the field of automatic sharpening and grinding devices for cutting tools, can solve the problems of reduced grinding precision and efficiency, potential safety hazards for operators, and excessive grinding, so as to improve grinding precision and efficiency, and improve lateral The effect of moving precision and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

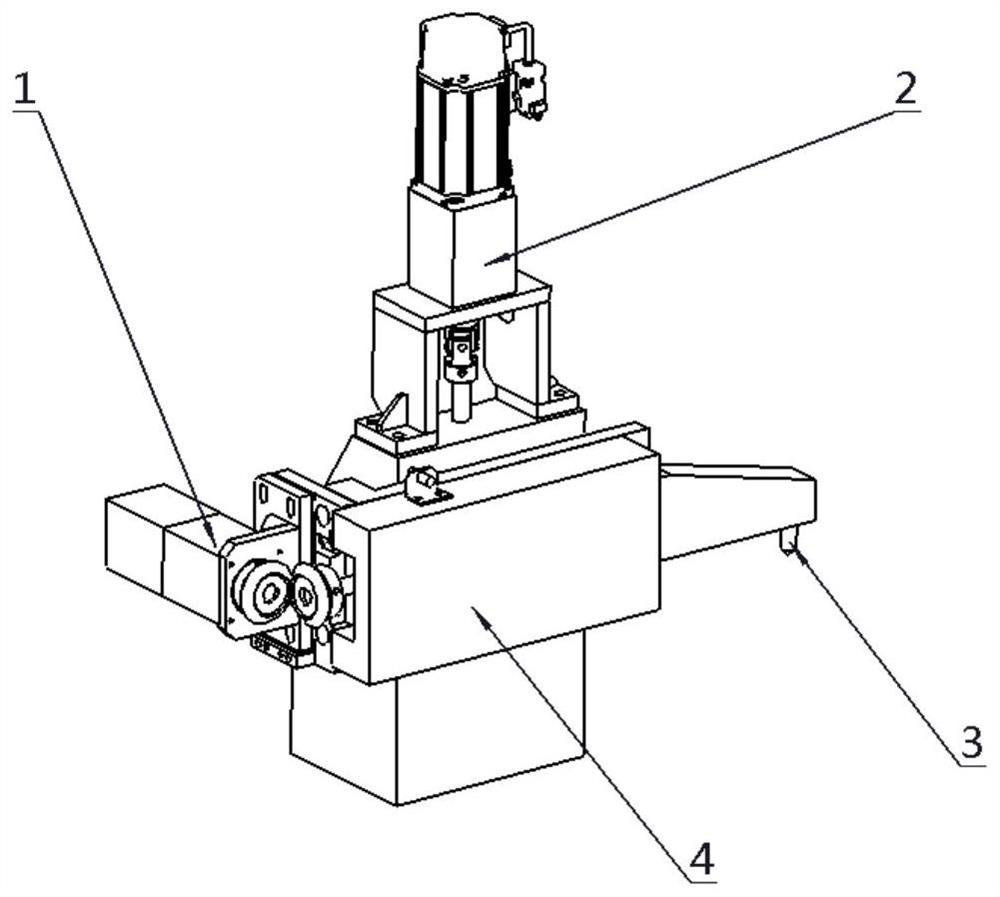

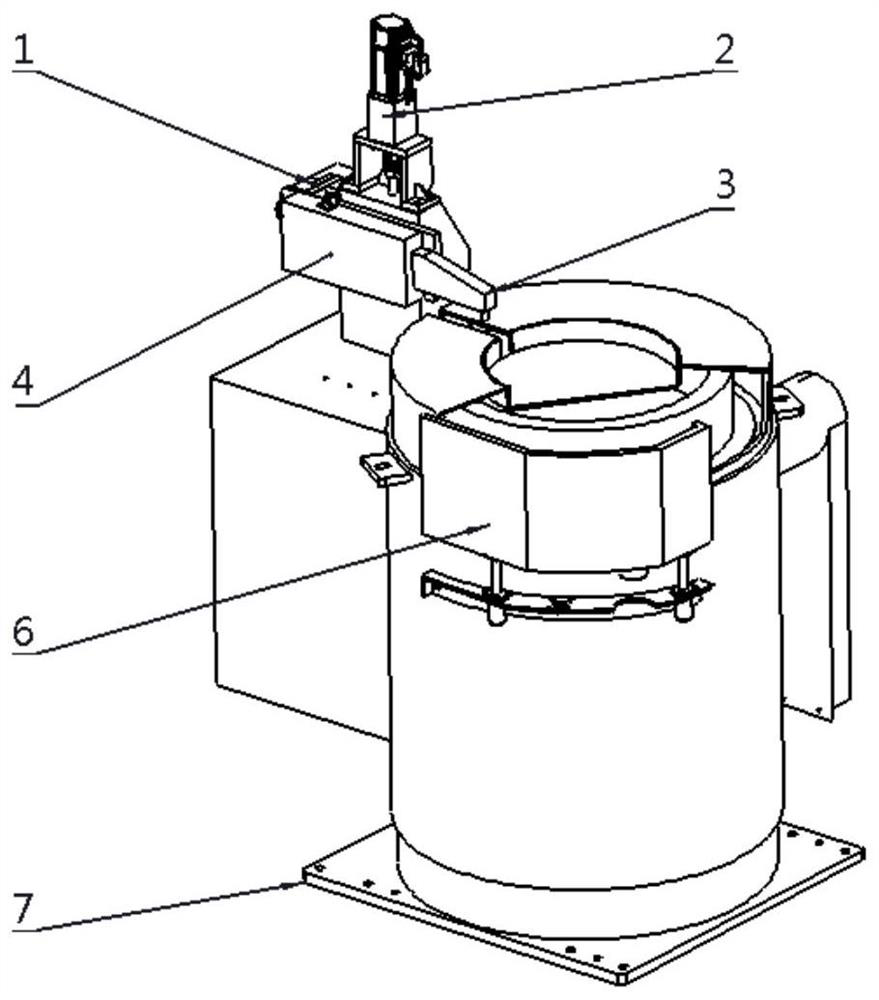

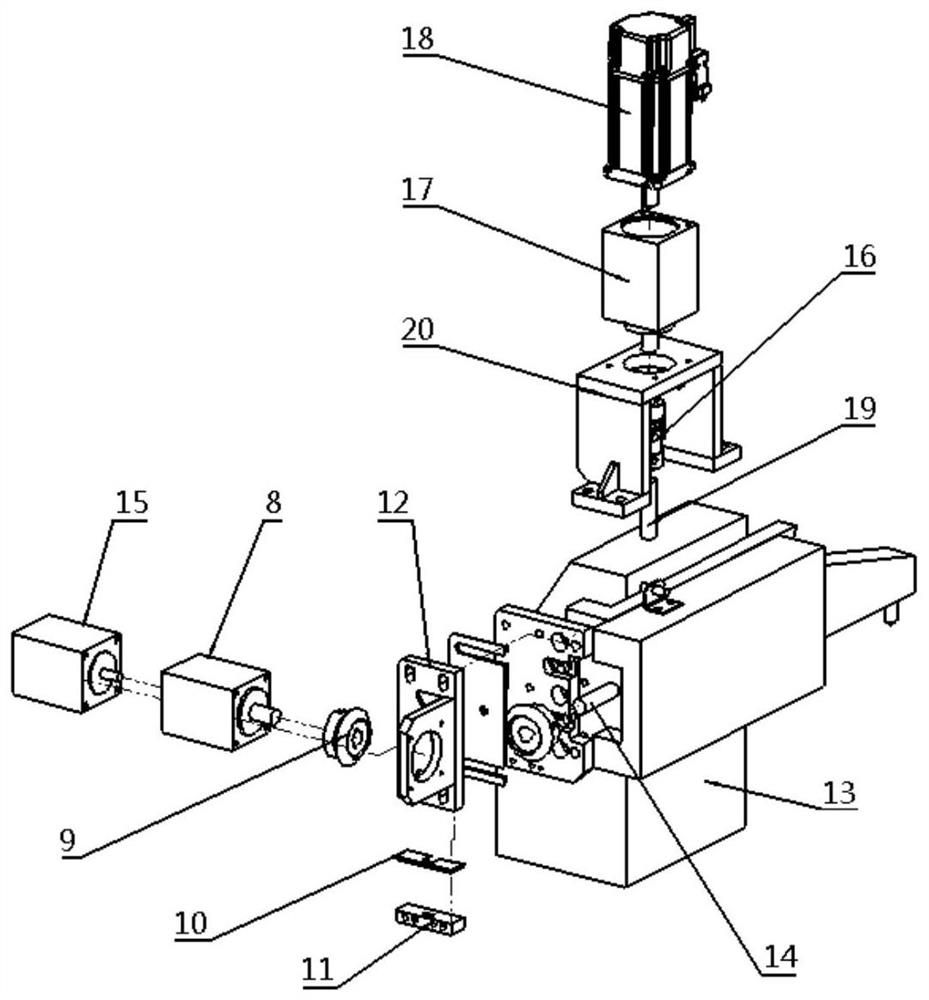

[0022] like figure 1 and image 3 As shown, the automatic sharpening and sharpening grinding wheel grinding device of the present invention includes a guard (not shown in the figure), and the guard is installed on the base. The lower part of the shield is provided with threaded holes for easy installation with other equipment. Shields are used to protect the internal structure from abrasive debris or liquids. A lateral adjustment mechanism 1, a longitudinal adjustment mechanism 2 and a diamond grinding head 3 are installed inside the shield. One side of the shield is provided with an opening, and the diamond grinding head 3 can protrude from the opening.

[0023] The horizontal adjustment mechanism 1 includes a horizontal linear transmission mechanism, which is installed on the sliding bracket 4, and a slide block is movably instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com