Variable empennage with built-in rotating flexible assembly and design method

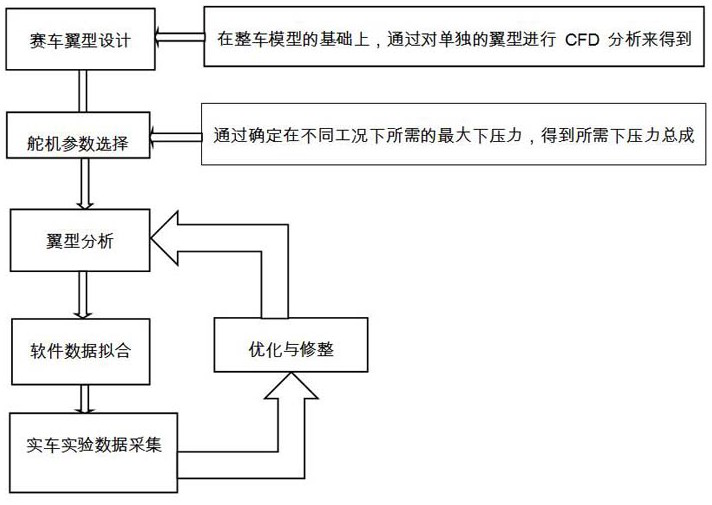

A rotary, tail-wing technology, applied in the field of aerodynamics, can solve problems such as stalling of racing cars and increased frictional resistance, and achieve the effects of being less prone to failure, improving reliability, and improving aerodynamic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

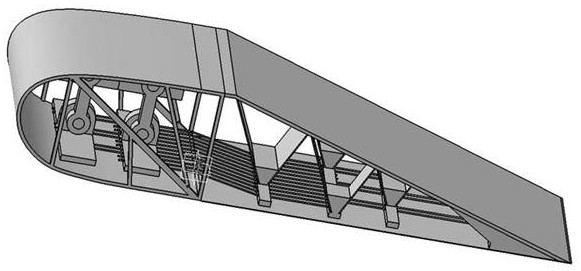

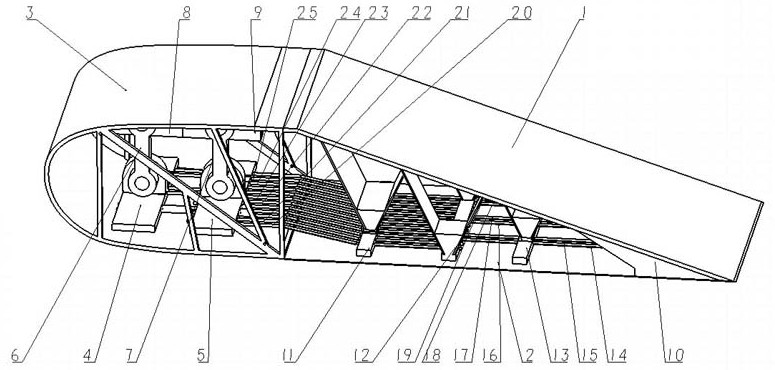

[0022] A variable tail with a built-in rotating flexible assembly, including an upper surface 1, a lower surface 2, a wing frame 3, a left traction plate 4, a right traction plate 5, a left connecting rod 6, a right connecting rod 7, and a left steering gear 8 , right steering gear 9, wing tail connection block 10, left traction block 11, middle traction block 12, right traction block 13, long iron wire one 14, long iron wire two 15, long iron wire three 16, long iron wire four 17, long iron wire five 18, long iron wire six 19, short iron wire one 20, short iron wire two 21, short iron wire three 22, short iron wire four 23, short iron wire five 24, short iron wire six 25, wherein flexible upper surface 1 and lower surface 2 are respectively fixed on the wing On the frame 3 and the wing tail connection block 10, the left steering gear 8 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com