Heavy-load stacking machine

A stacker and lifting platform technology, applied in the field of logistics equipment, can solve the problems of damaged goods transportation time economic loss, poor stability, low safety performance, etc., to facilitate transportation and on-site installation, ensure accuracy, and ensure safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

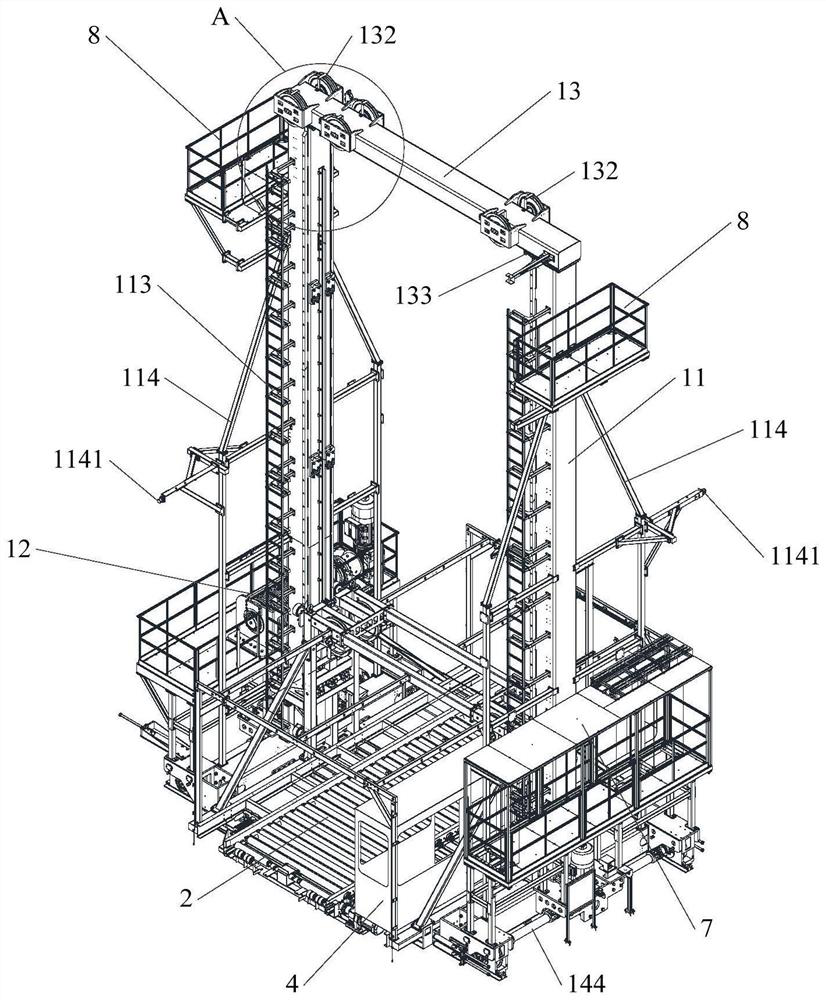

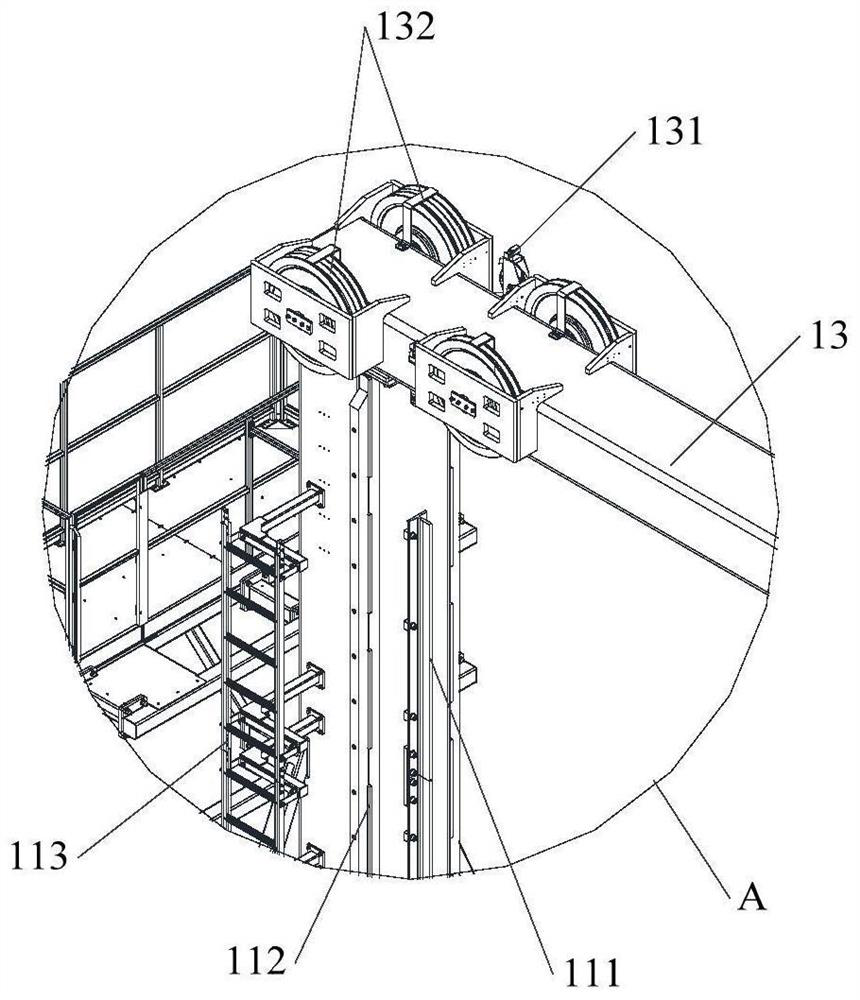

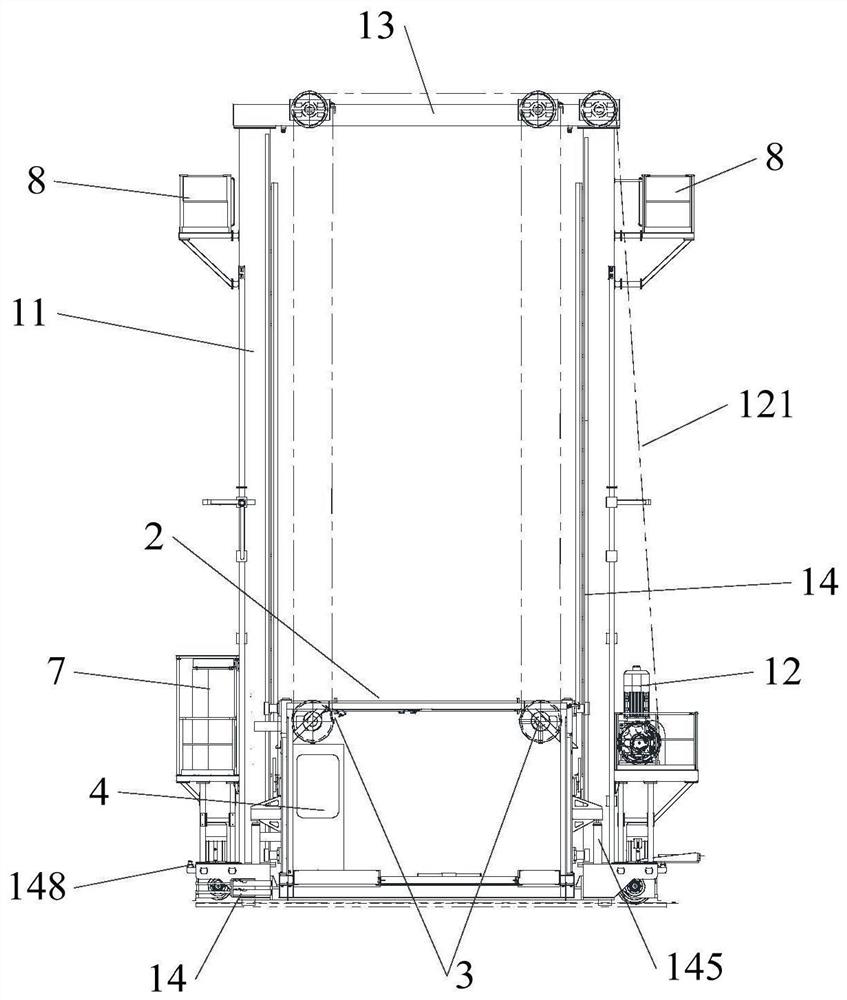

Embodiment 1

[0045] Such as Figure 1-5 As shown, the application provides a heavy-duty stacker, which includes a gantry and a lifting platform 2, and the gantry is formed by connecting a top beam 13, a bottom frame 14 and two columns 11, and the gantry is The main force-bearing member when transporting heavy-duty materials. A plurality of fixed pulleys 132 are arranged on the top beam 13, and an operation platform 7 and a driving device 12 are respectively arranged on both sides of the gantry frame. The driving device 12 is connected with the fixed pulleys 132 through the first wire rope 121, and the driving device 12 is used to drive the lifting platform. 2 for lifting. The operating table 7 is provided with a stacker control system, which can be used by staff for debugging and operating equipment. The bottom frame 14 is provided with two beams 141, and each beam 141 is fixedly connected with a travel motor 142, the output end of the travel motor 142 is connected with a transmission sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com