Early warning method and system for temperature of continuous annealing furnace

A technology for continuous annealing furnaces and annealing furnaces, applied in furnaces, heat treatment furnaces, furnace types, etc., can solve problems such as failure to meet high production requirements, failure to achieve early warning and reminders of deterioration trends, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

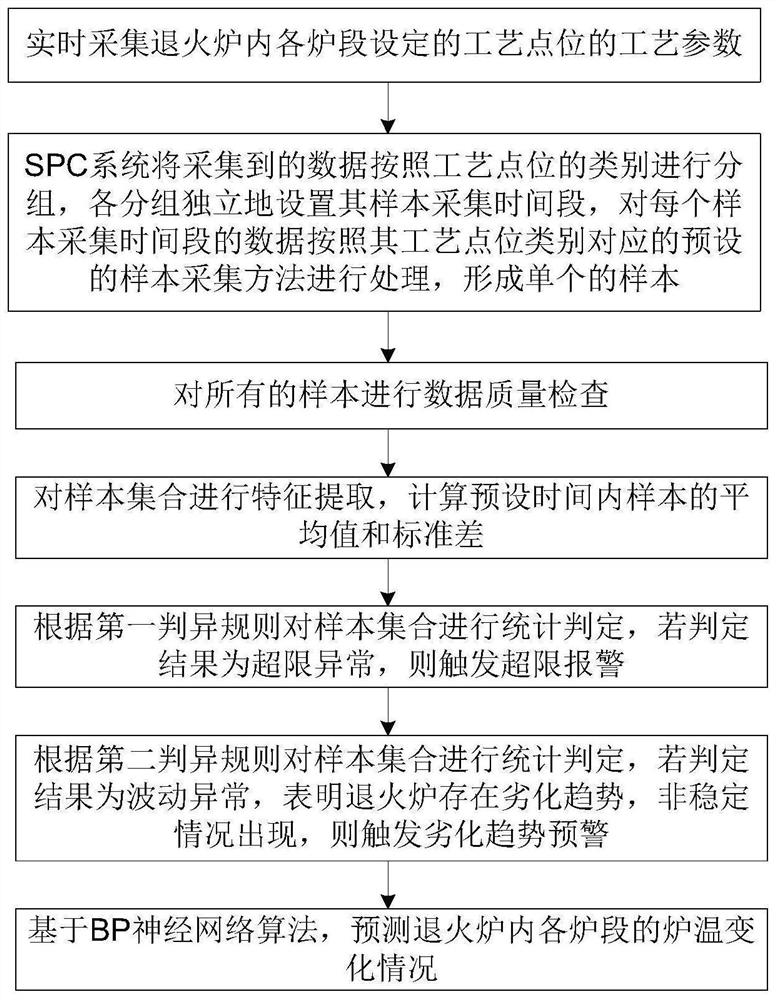

Method used

Image

Examples

Embodiment

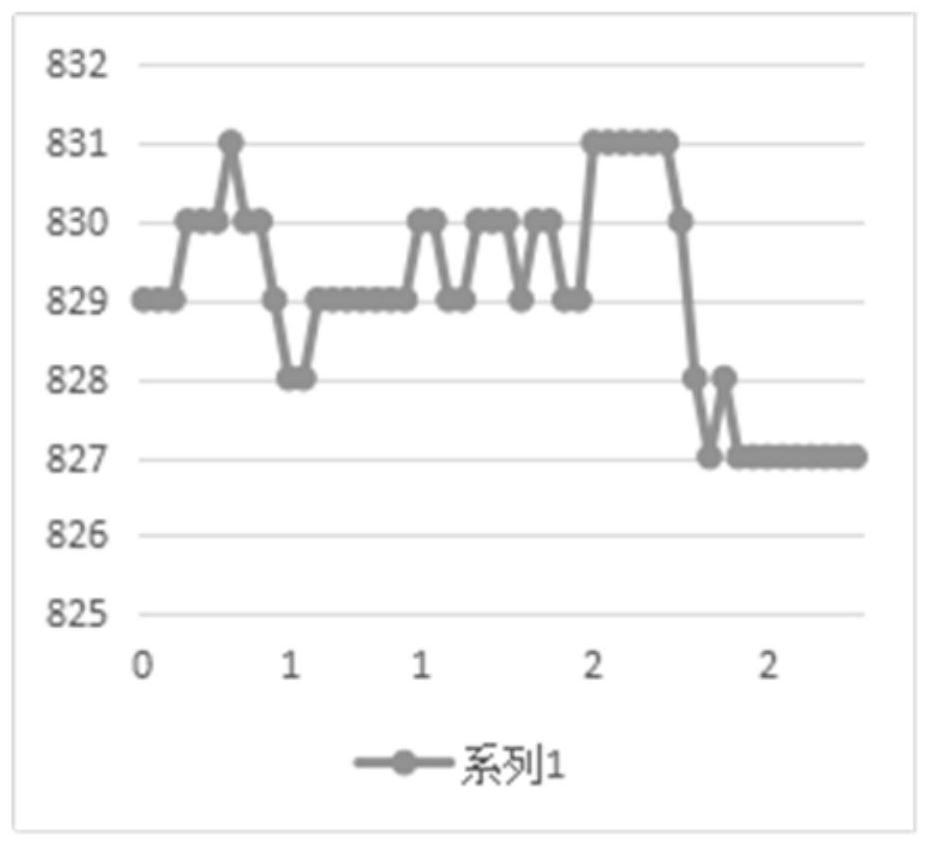

[0074] The essence of the early warning of furnace health is the early warning of the important indicators of each furnace section. Therefore, the important parameters and reasonable ranges of each furnace section must be confirmed first. The specific content is shown in Table 1. Furnace section health evaluation program.

[0075] Table 1 Health evaluation scheme of each furnace section

[0076]

[0077] The electrical control unit of the cold rolling annealing furnace has two parts, namely DCS and PLC. Confirm the data address of the required process point and automatically collect this part of the process point. See Table 2, this part of the process points can include oxygen content, hydrogen content, dew point of furnace atmosphere, furnace pressure, target plate temperature, roller tension, steel coil number, furnace temperature, steel coil specification, unit speed, plate Gentle exhaust.

[0078] Table 2 Important process points and their corresponding addresses

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com