Electroplating module

A technology of modules and components, applied in the direction of electrolysis components, electrolysis process, etc., can solve the problems of serious driving energy consumption, complicated maintenance, and large stress on the entire growth line, and achieve high production efficiency, simple screening, and small footprint small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

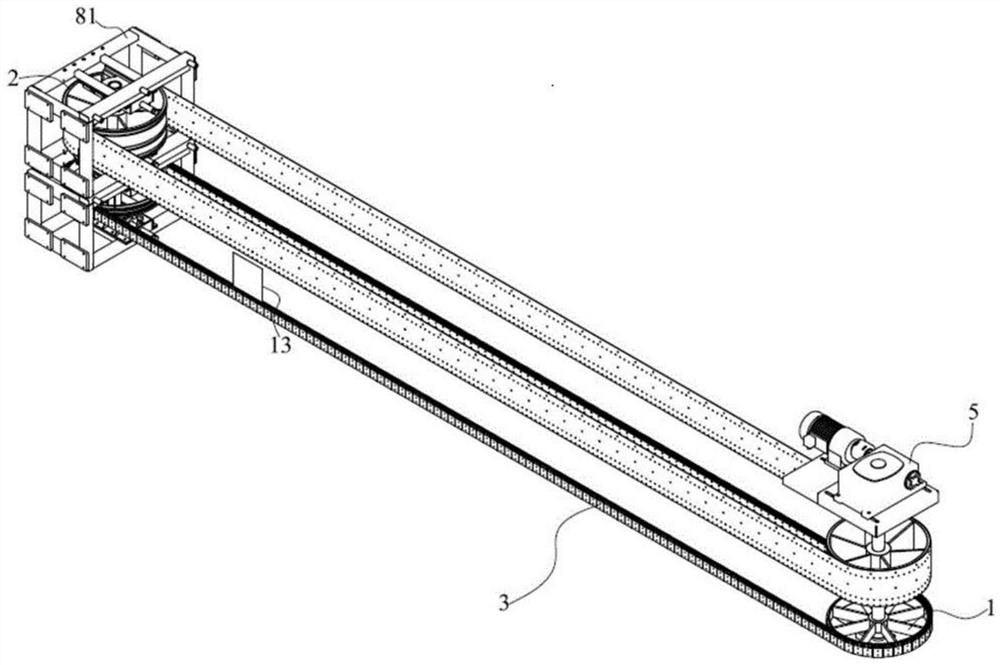

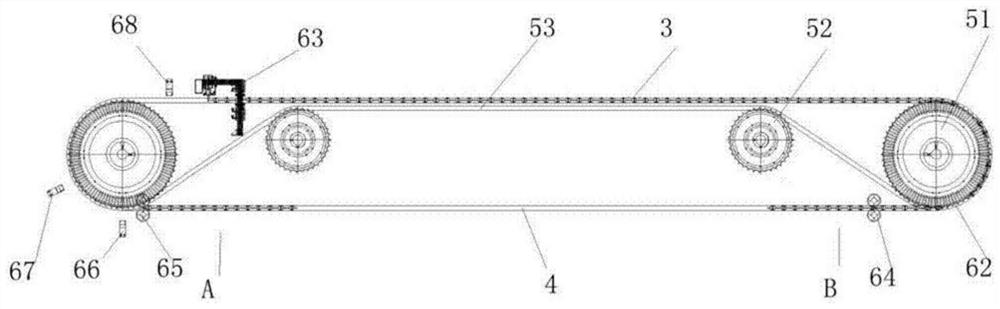

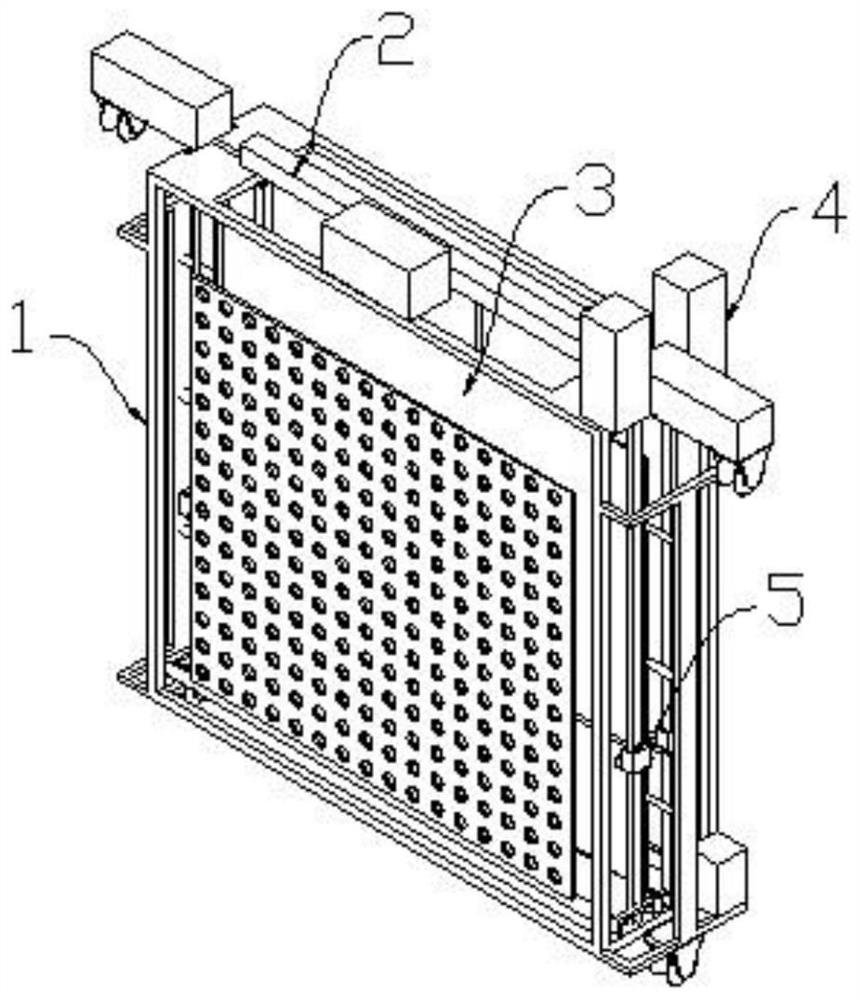

[0029] see figure 1 , figure 2 , image 3 , Figure 8 and Figure 9 As shown, the electroplating module realized by the present invention includes: a module frame 1, which is used to install various mechanical parts; a clamping device 2, which is arranged on the module frame 1, The substrate 3 is clamped; the linear movement assembly 4, more than one pair, is arranged on the module frame 1; the jet flow device 5, which is installed on the linear movement assembly 4, moves along with the linear movement assembly 4 Move, jet stream on the substrate 3 .

[0030] In view of the fact that the vertical continuous electroplating equipment currently on the market adopts a large-scale production line, and even the production line is set to more than 40 meters, the entire production line of more than 40 meters needs to clamp the substrate 3, and the entire production line bears too much. In the actual production process Among them, the installation period is long, the installation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com