Sliding hanging basket for repairing and cleaning stay cable sleeve of cable-stayed bridge

A technology of cable-stayed cables and cable-stayed bridges, which is applied in the field of cable-stayed bridge cable-stayed casing repairs and cleaning sliding baskets, which can solve the problems of low work efficiency, high mechanical cost investment, omissions, etc., and achieve high work efficiency and mechanical The effect of low cost input and improved practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

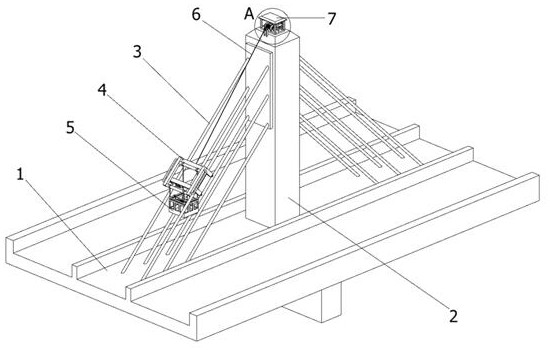

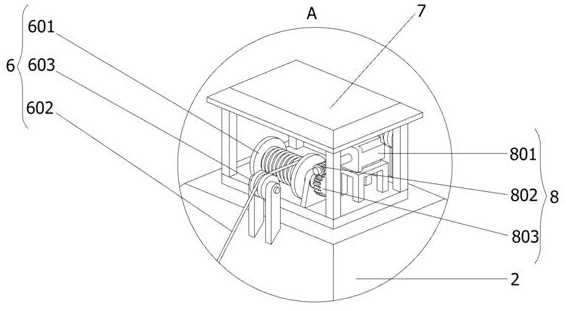

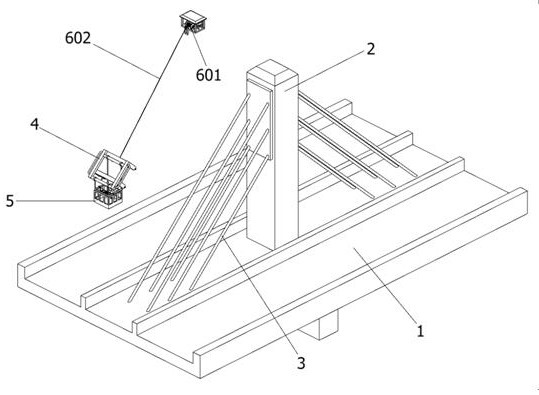

[0031]As attachedfigure 1 AttachedFigure 7Shown:

[0032]The present invention provides a sliding gondola used for repairing and cleaning cable-stayed bridge cable casing. It includes a main beam 1, a main tower 2 is provided in the middle of the upper end surface of the main beam 1, and the front and rear ends of the main tower 2 are connected to each other. Six stay cables 3 are connected symmetrically between the upper end faces of the main beam 1; each stay cable 3 is sleeved with a casing; the two stay cables 3 on the front side are slidably connected with a sliding mechanism 4, The sliding mechanism 4 includes a zigzag bracket 401, a walking pulley 402, and a limit plate 403. The bottom of the sliding mechanism 4 is symmetrically provided with four zigzag brackets 401, and the inside of each zigzag bracket 401 is rotatably connected with one through a rotating shaft. For the walking pulley 402, a limit plate 403 is rotatably connected to the bottom end surface of one side of each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com