Puncture force measuring device and measuring method based on laser speckle interference principle

A laser speckle and measurement device technology, which is applied in the direction of measurement devices, puncture needles, and measurement forces, can solve the problems of inability to accurately obtain the force close to the puncture tip, large interference factors of tip puncture force, and low precision, so as to reduce The effects of information loss, low measurement environment requirements, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

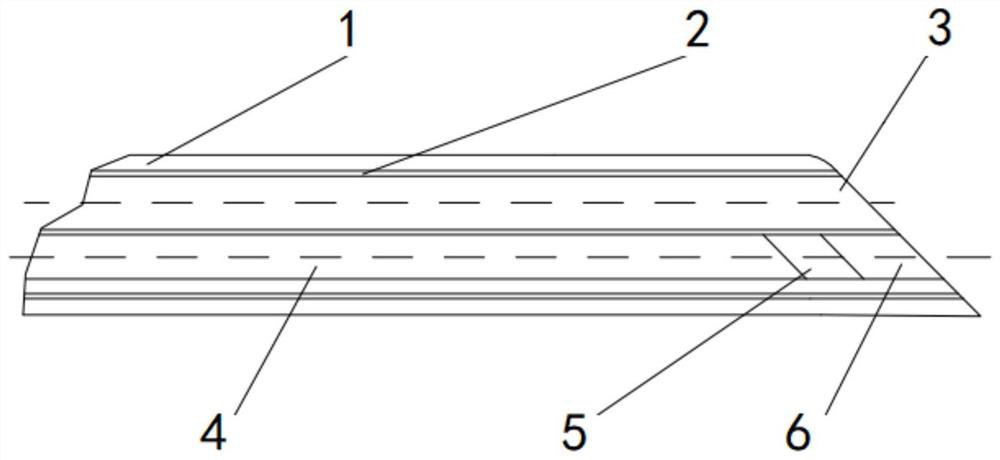

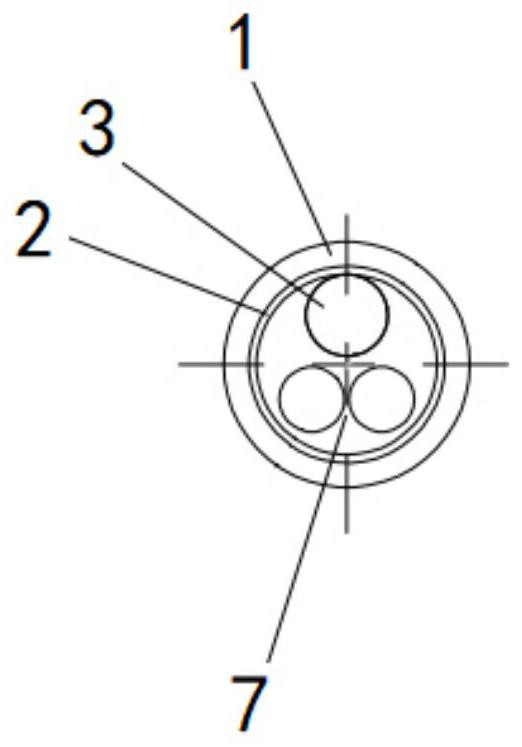

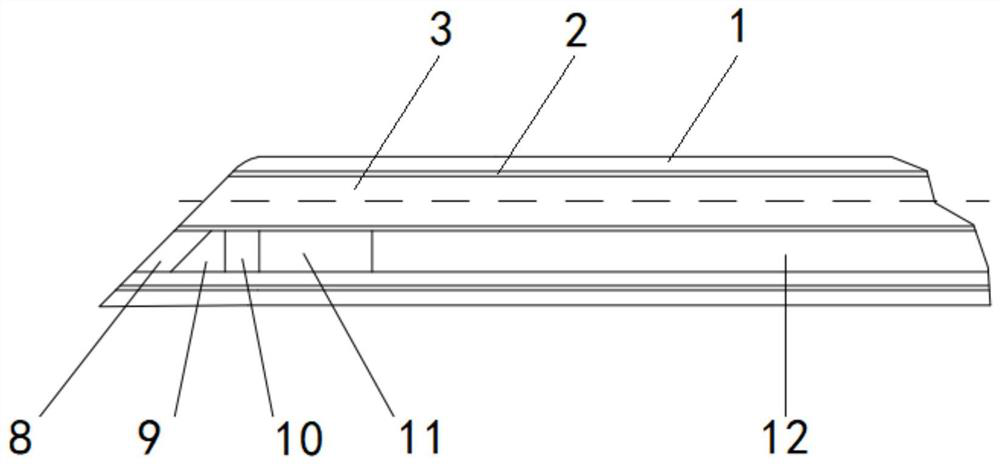

[0048] as attached Figure 1 to Figure 3 As shown, a puncture force measurement device based on the principle of laser speckle interference includes a housing, a needle insertion unit, a laser irradiation unit and a camera unit.

[0049] (1) Housing

[0050] The outer shell includes an outer protective sheath 1 and an inner soft sleeve 2 , and the inner soft sheath 2 is arranged inside the outer protective sheath 1 . The outer protective sheath 1 is provided with a needle outlet duct 3, a lighting duct and a camera duct, the needle outlet duct 3, the lighting duct and the camera duct are arranged side by side in the longitudinal direction, and arranged in a triangular shape in the transverse direction. The needle pipeline 3 is located at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com