Marking quick positioning device with detection function

A positioning device and marking technology, which is applied in the direction of measuring devices, vehicle testing, mechanical parts testing, etc., can solve the problems of missing or not drilling through the glue injection hole, and prone to misjudgment, etc., to achieve fast clamping and structure Reasonable design and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

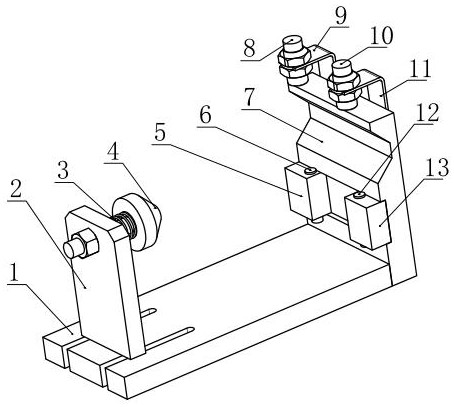

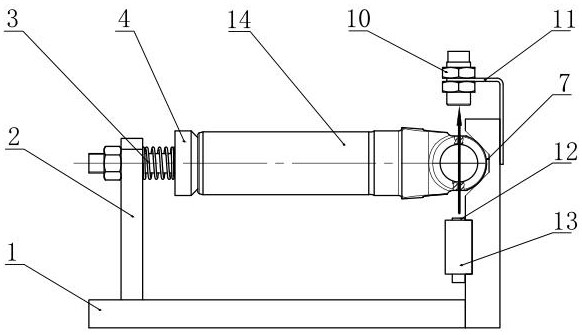

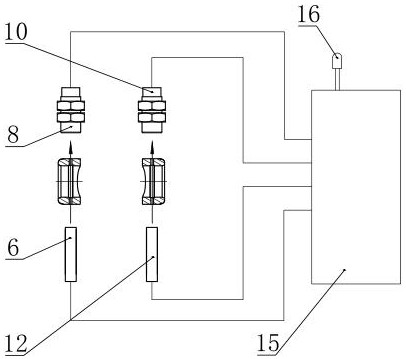

[0017] according to Figure 1~4 The specific structure of the present invention will be described in detail. This fast marking device with detection function includes a base 1 with a sliding fork 14 sandwiched between a positioning plate 7 and a tail sliding adjustment plate 2, a photoelectric sensing element assembled on the positioning plate 7 of the base 1 and a corresponding control circuit and The control cabinet 15 etc. parts of warning light 16. The positioning plate 7 of the base 1 is provided with a V-shaped groove, and the head of the sliding fork 14 drilled with a glue injection hole is inserted into the V-shaped groove of the positioning plate 7, and is clamped by the tail sliding adjustment plate 2 assembled on the base 1. Slide fork 14. The positioning center 4 is tensioned by the adjusting nut and the spring 3 on the tail sliding adjustment plate 2, and the positioning center 4 tensioned by the spring 3 moves axially under the action of an external force, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com