Tire with Reuleaux triangle inner cavity, and processing method of tire

A triangular, inner cavity technology, applied to tire parts, tires, non-pneumatic tires, etc., can solve the problem of not being able to effectively balance strength and comfort, achieve good strength and stability, uniform force, and reduce energy loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

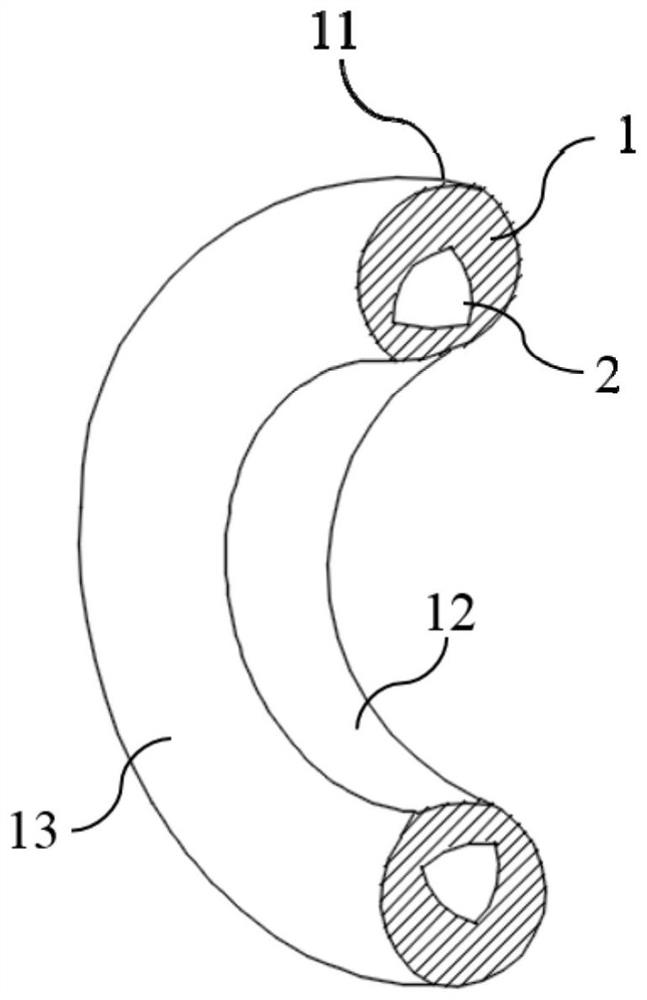

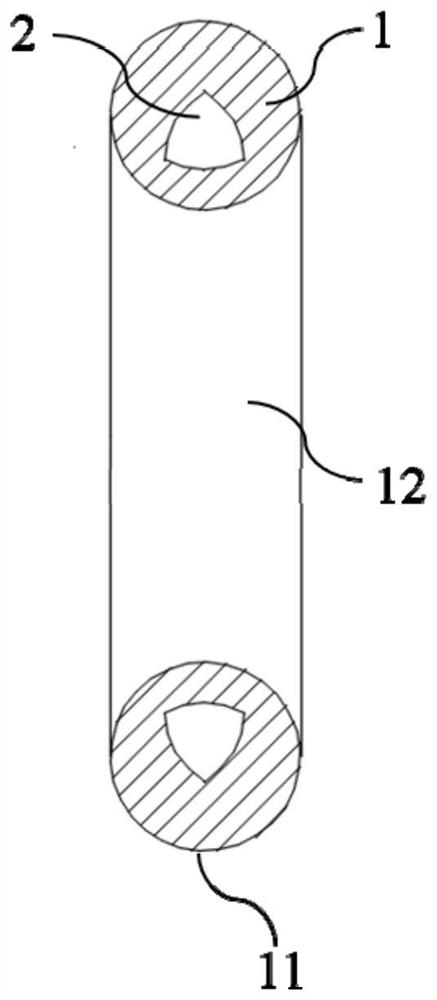

[0065] A kind of inner chamber of the present embodiment is the tire of the shape of Lelo triangle, such as Figure 1~2 As shown, it includes a tire green strip 1 extruded by a screw extruder. The tire green strip 1 includes a crown 11, a tire belly 12 and a sidewall part 13, and the sidewall part 13 is wrapped around the periphery of the rim. The core of the tire billet 1 is provided with an inner cavity support portion along its circumference, and the inner cavity support portion is a closed Lello triangular inner cavity 2 in a longitudinal section shape. Since the Lello triangle has both triangular stability and roundness The whole shape is uniformly stressed, and its strength and stability are good; combined with the material formula of the tire, the size of a single Lello triangular inner cavity 2 accounts for 30% to 60% of the cross-sectional size of the tire, so as to ensure the load and stability of the tire. Comfort requirements, if the load and comfort are met, the h...

Embodiment 2

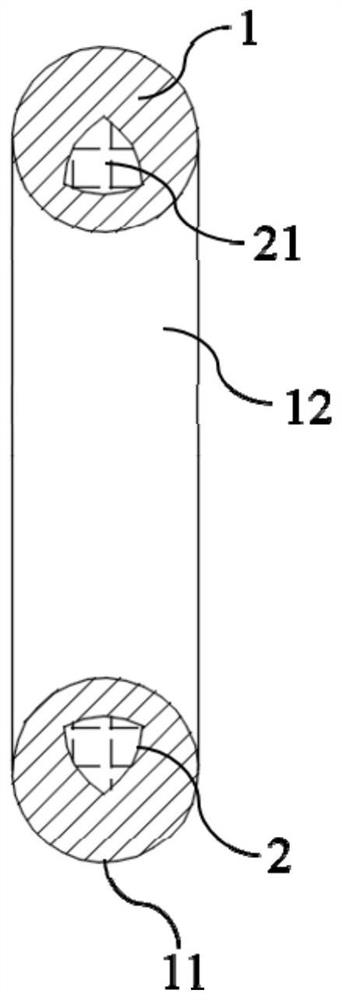

[0068] A kind of inner chamber of the present embodiment is the tire of the shape of Lai Luo triangle, and basic structure is the same as embodiment 1, difference and improvement are: as image 3As shown, the elastic medium 21 is filled in the inner cavity 2 of the Laylo triangle, and the elastic medium 21 is a gas medium or a solid medium, and the gaseous state is mainly an inert gas such as nitrogen, and the solid one is a non-metallic elastic medium, mainly composed of non-metallic elastic medium. Metal elastic members such as plastics or foaming and other lightweight cushioning materials, etc., so that the tire has good support strength during riding, and can also have riding comfort, and can reduce the weight of the tire and reduce the riding process. energy loss.

Embodiment 3

[0070] A kind of inner chamber of the present embodiment is the tire of the triangular shape of Lai Luo, and basic structure is the same as embodiment 2, difference and improvement are: as Figure 14 As shown, an elastic member 4 is placed in the Rilo triangular inner cavity 2 along its circumference, and the outside of the elastic member 4 is in contact with the inner wall of the Rilo triangular inner cavity 2 and is partially embedded in the tire on the periphery of the inner cavity. In the embryonic strip 1, thereby preventing the elastic member 4 from sliding in the inner cavity 2 of the Leroy triangle, thereby affecting the force uniformity of the tire. When the tire is under stress, the elastic member 4 plays a supporting role in the interior of the Lello triangular cavity 2. Due to the nature of the elastic member 4 itself, it can also reduce the stress concentration caused by the pressure of the tire and ensure the comfort of riding. performance, and can save energy co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com