Pyrolysis water purification circulating device

A circulating device and water purification technology, applied in heating water/sewage treatment, grease/oily substance/float removal device, sedimentation treatment, etc. It can solve the problem of blocked pipes, intermediate parts of nozzles, increased product maintenance costs, and increased costs. and other problems, to achieve the effect of rapid separation, low use cost and reduced processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

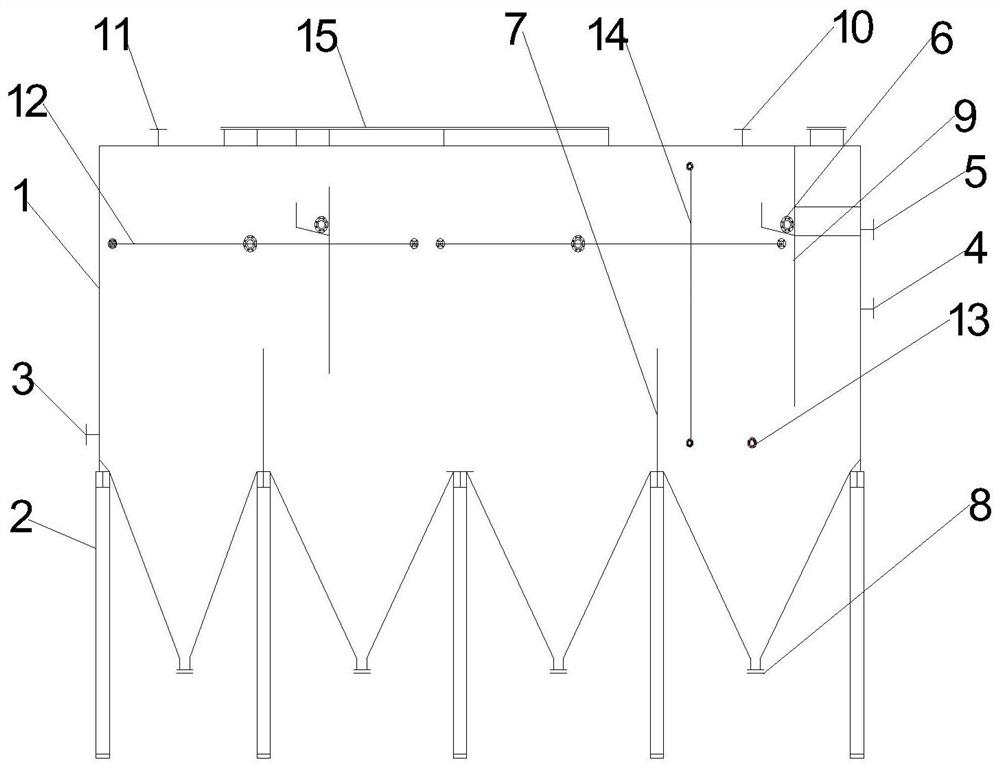

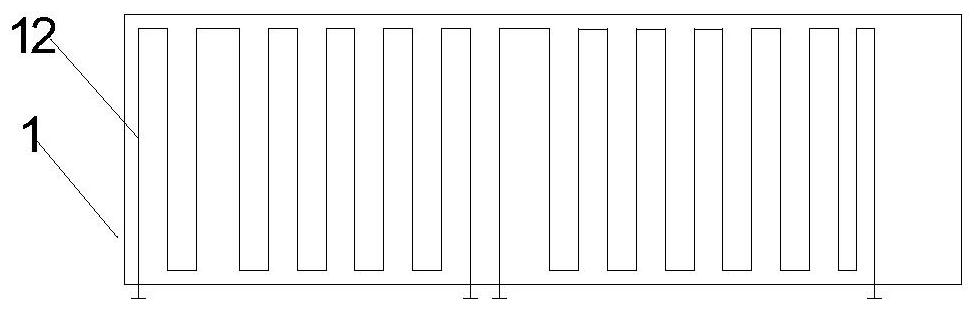

[0010] figure 1 According to the present invention, a specific embodiment of the structure of a pyrolyzed water purification cycle device is provided.

[0011] First, the pyrolysis water flows into the oil-water separation box 1 from the liquid inlet 3 through the pipeline. After physical precipitation, the isolation baffle blocks the residues whose specific gravity is greater than water during the flow process, and the residues settle with gravity and slide down on the V-shaped oil-water The cavities in which the separation box contains residues are discharged through connection with external pipelines through the residue collection port. Through the interaction of multiple isolation baffles a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com