A device and method for degrading ammonium perchlorate wastewater by hydrothermal combined biological method

An ammonium perchlorate, combined biological technology, applied in the methods of using microorganisms, biochemical equipment and methods, microorganisms, etc., to achieve the effect of reducing operating costs and reducing environmental pollution loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

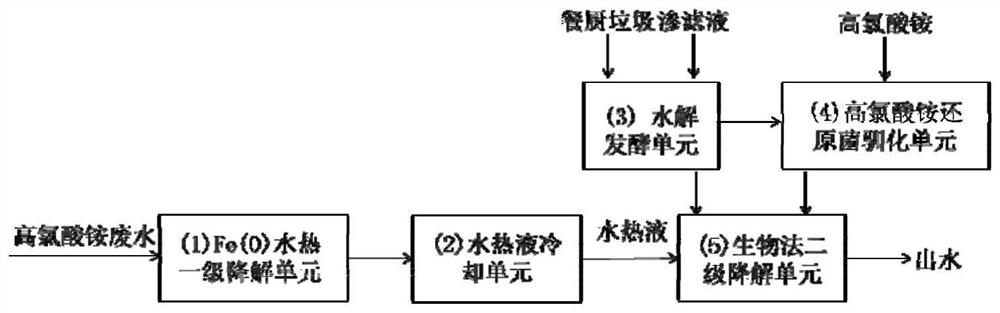

[0057] A method of hydrothermal combined biological method for degrading ammonium perchlorate wastewater according to the embodiment of the present invention comprises the following steps:

[0058] Step 1, mixing Fe(0) and ammonium perchlorate waste water, adjusting the pH of the reaction system to acidic conditions, carrying out the first-order reduction degradation of ammonium perchlorate, and obtaining the ammonium perchlorate hydrothermal solution after the first-order degradation;

[0059] Step 2, cooling the ammonium perchlorate hydrothermal solution after the primary degradation obtained in step 1, to obtain the cooled ammonium perchlorate hydrothermal solution;

[0060] In step 3, the cooled ammonium perchlorate hydrothermal solution obtained in step 2 is subjected to secondary degradation by the biological method, and discharged after the treatment reaches the standard; wherein, the supernatant of the stage of hydrolysis and fermentation of food waste and landfill leac...

Embodiment 2

[0064] The difference between the embodiment of the present invention and embodiment 1 is that in step 1, ammonium perchlorate wastewater is subjected to primary reduction degradation under high temperature and pressure conditions; wherein, the high temperature value is 200°C, and the pressure value is 1.554Mpa ; In step 2, the cooling temperature is 37°C during cooling; the successfully domesticated ammonium perchlorate reducing bacteria are inoculated into the secondary degradation unit of the biological method, and the inoculum amount is equal to 5% of the substrate.

Embodiment 3

[0066] The difference between the embodiment of the present invention and embodiment 1 is that in step 1, ammonium perchlorate wastewater is subjected to primary reduction degradation under high temperature and pressure conditions; wherein, the high temperature value is 210°C, and the pressure value is 1.906Mpa; In step 2, the cooling temperature is 36° C.; the ammonium perchlorate-reducing bacteria that have been successfully acclimatized are inoculated into the secondary degradation unit of the biological method, and the inoculum amount is equal to 5% of the substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com