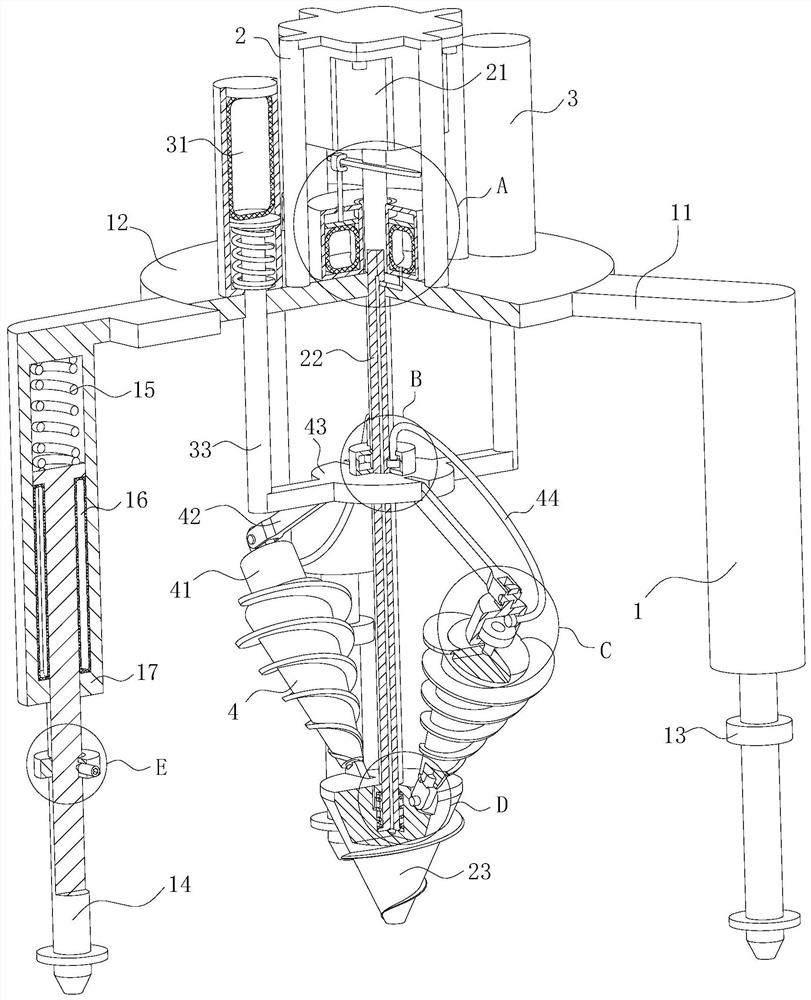

Nursery stock planter

A technology for planting machines and seedlings, applied in planting methods, soil clod crushers, agricultural machinery and implements, etc., can solve the problems of inability to adjust the size of planting pits and inconvenient control of the depth of planting pits, so as to improve seedling planting efficiency and improve Effect and efficiency, the effect of increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

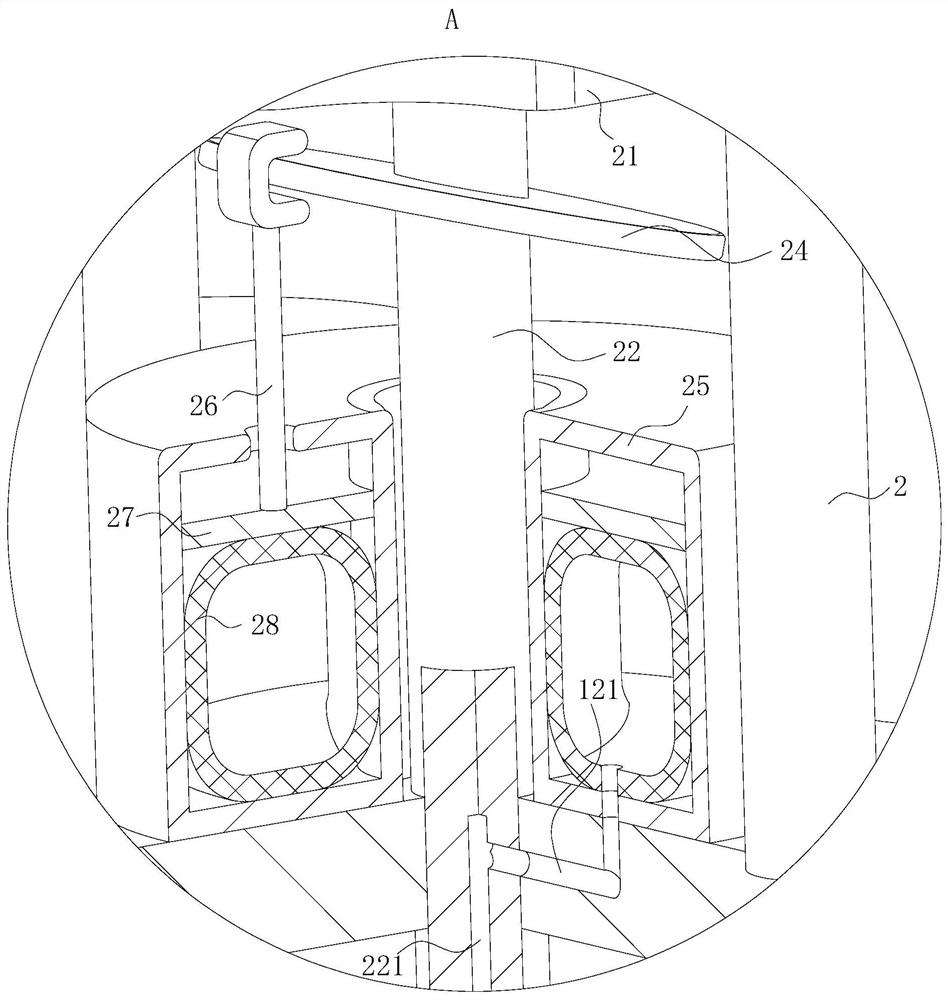

Embodiment approach

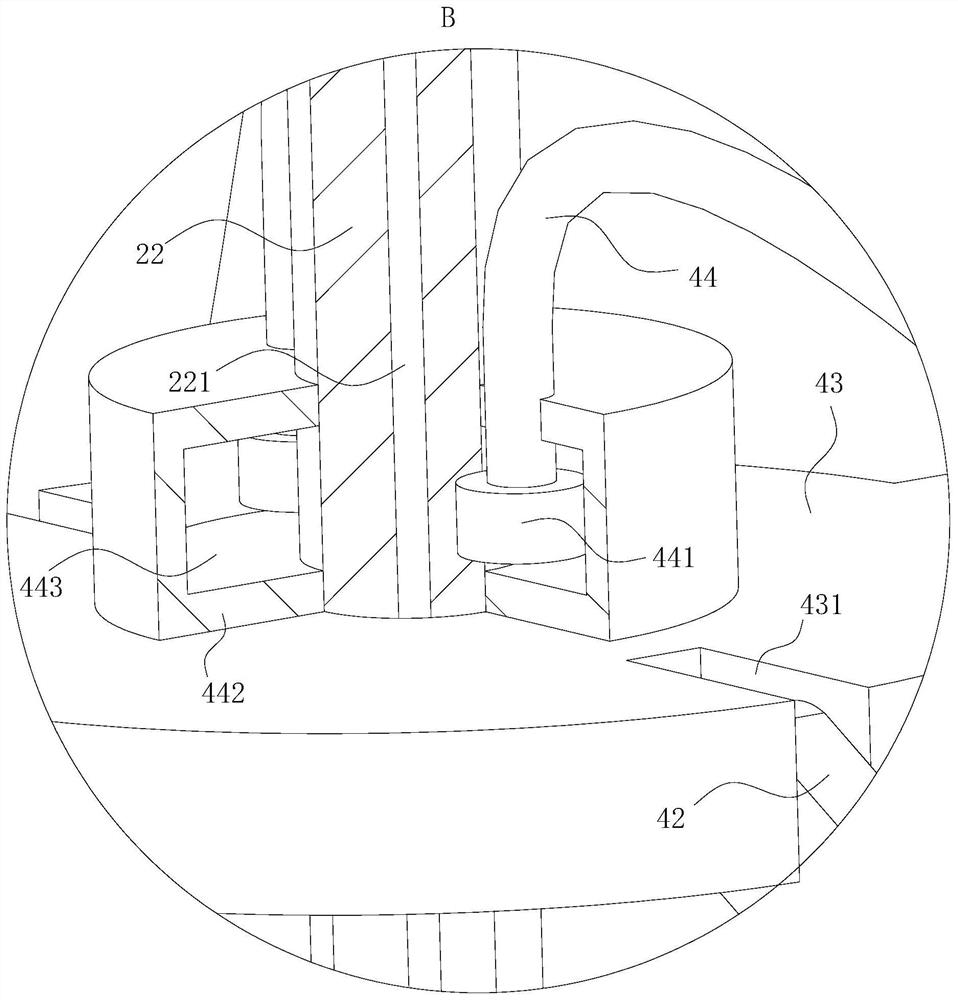

[0031] As an embodiment of the present invention, a fixed block 442 is slidably installed on the rotating shaft 22; the fixed block 442 is located between the mounting plate 12 and the fixed plate 43; a cavity 1 443 is opened inside the fixed block 442; The rotating shaft 22 runs through the first cavity 443; the fixed block 442 is fixed with a flexible shaft 44; the end of the flexible shaft 44 on the fixed block 442 extends into the first cavity 443; the flexible shaft 44 A friction wheel 1 441 is fixedly mounted on the end of the cavity 1 443; the center line of the friction wheel 1 441 is parallel to the center line of the rotating shaft 22, and the friction wheel 1 441 can be in close contact with the surface of the rotating shaft 22 to transmit power The inside of the connection block 41 is provided with a cavity two; the connection block 41 is equipped with an installation shaft 412; the installation shaft 412 can rotate relative to the connection block 41; one end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com