Process equipment used for large-size bowl-shaped structural part preforming

A technology for process equipment and structural parts is applied in the field of process equipment for pre-forming large-sized bowl-shaped structural parts, which can solve problems such as edge wrinkling, reduce wall thickness difference, reduce spinning deformation, and increase anti-instability effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

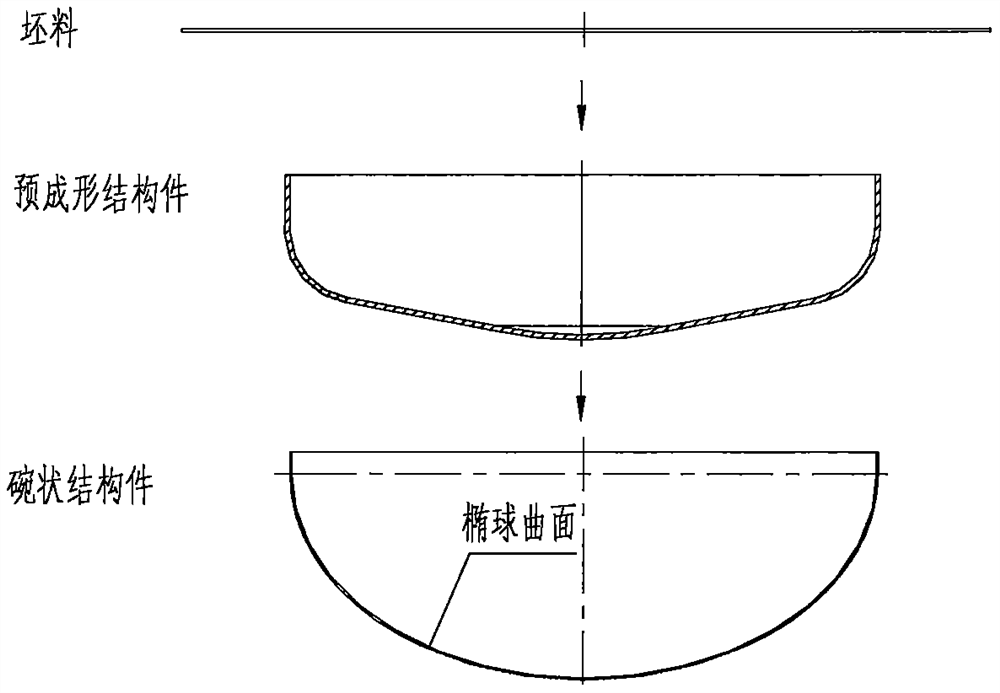

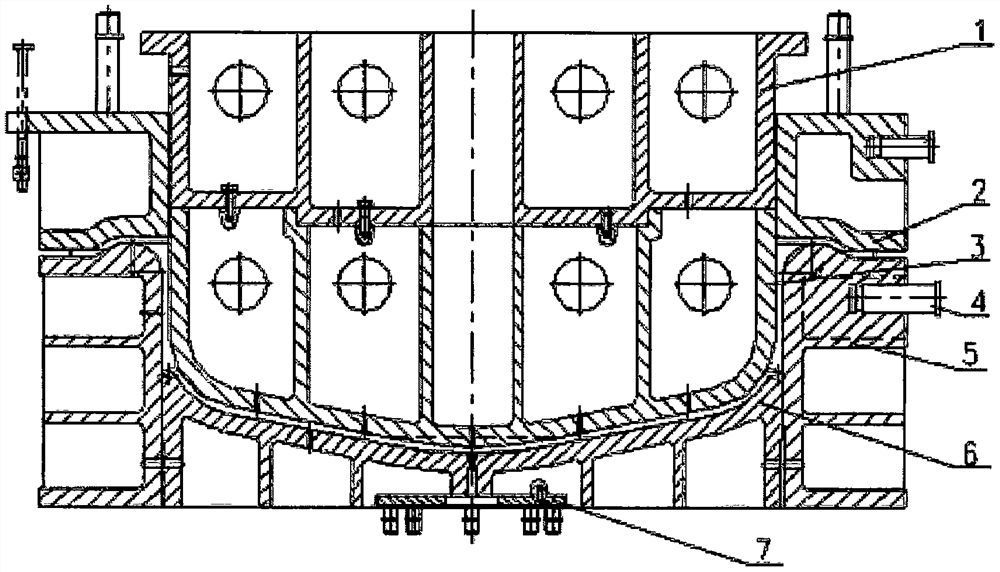

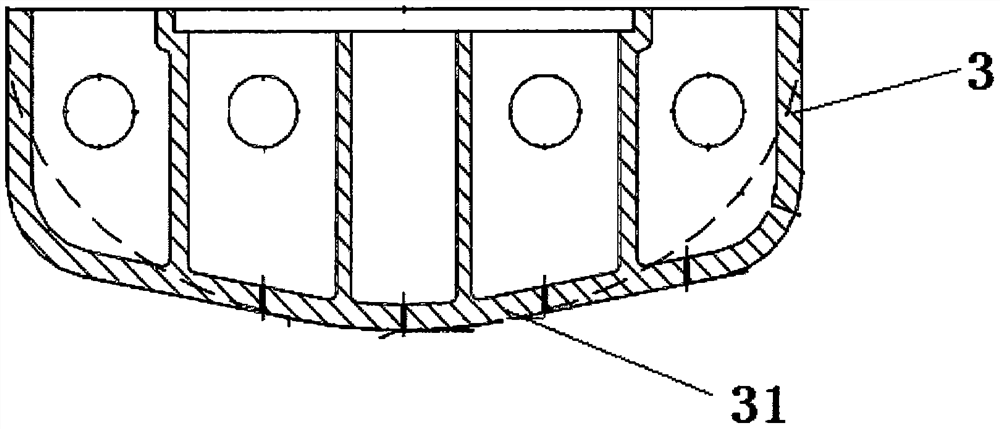

[0035] In order to realize the pre-forming of large-sized bowl-shaped structural parts and ensure that the forming accuracy and quality meet the requirements, the present invention optimizes the parameters of the forming surface of the punch and specially designs the structural parameters of the forming tool. The specific implementation methods are as follows:

[0036] In order to ensure the stability of spinning and the forming accuracy of the final part, the design of the preformed surface is optimized through calculation and repeated demonstrations, and the characteristic parameters of the forming surface of the punch are obtained as follows: image 3 As shown; the process provides a circular plate with a blank size of 3200mm in diameter. During the forming process, the blank must all enter the forming area, and ensure the forming of a straight line section with a length of the outer cylindrical section ≥ 200mm and a partial ellipsoid at the bottom;

[0037] The bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com