Reinforced composite material fold channel sandwich structure as well as preparation method and application thereof

A composite material, sandwich structure technology, applied in the superstructure, chemical instruments and methods, transportation and packaging, etc., can solve the problems of mechanical properties to be improved, the preparation process of the sandwich structure is complicated, etc., to improve the scope and potential of engineering applications , improve the anti-instability ability, improve the effect of carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

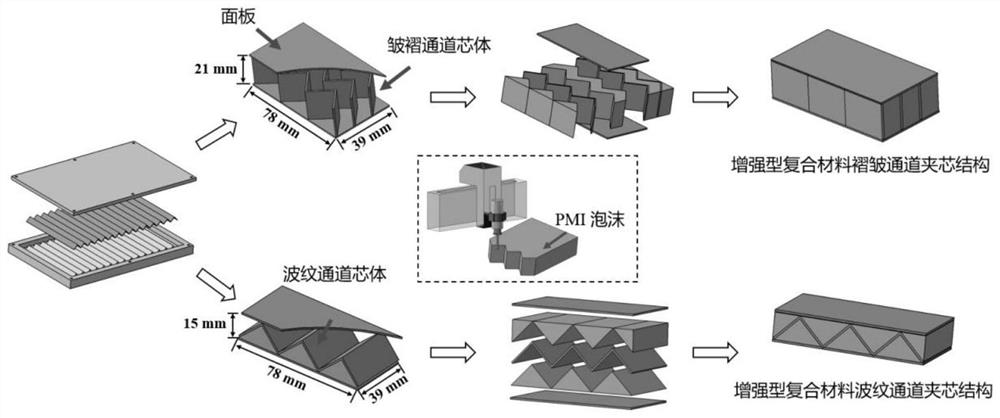

[0037] The present invention also provides a method for preparing the reinforced composite wrinkled channel sandwich structure described in the above technical solution, comprising the following steps:

[0038] arranging several corrugated plates in parallel at intervals in the horizontal direction, the corrugations of the corrugated plates are perpendicular to the horizontal plane, and filling foam in the gaps between the corrugated plates to obtain a foam-coupled corrugated core;

[0039] The foam coupling pleated core is bonded between the upper panel and the lower panel, and after curing, a reinforced composite material pleated channel sandwich structure is obtained.

[0040] In the present invention, several corrugated boards are arranged in parallel at intervals in the horizontal direction, and the folds of the corrugated boards are perpendicular to the horizontal plane, and foam is filled in the gaps between the corrugated boards to obtain a foam-coupled corrugated core....

Embodiment 1

[0047] The flowchart of preparing reinforced composite wrinkled channel sandwich structure in this example is as follows figure 1 shown.

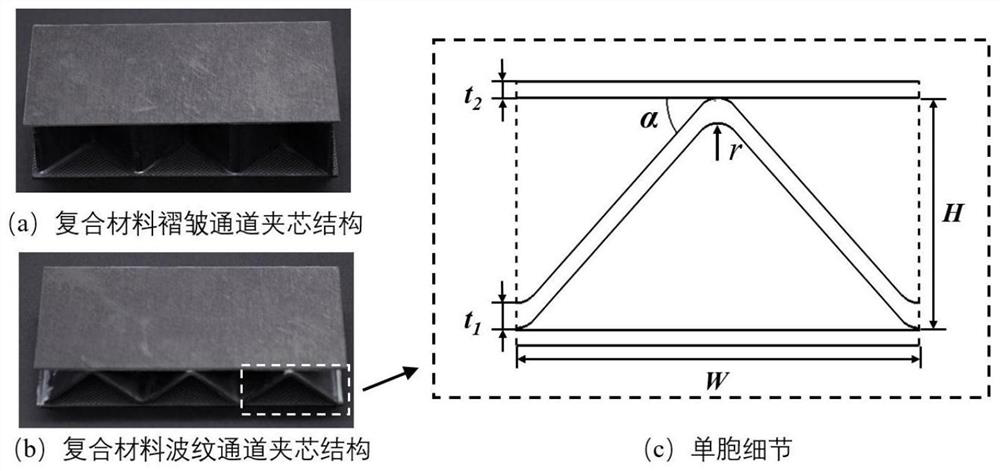

[0048] Arrange three corrugated plates in parallel and evenly spaced on the lower panel, and the corrugation of each corrugated plate is perpendicular to the lower panel to form a corrugated channel core; foam is filled into the voids of the corrugated channel core, the upper surface covers the upper panel, and The components are bonded by epoxy resin to obtain a reinforced composite corrugated channel sandwich structure.

[0049] The preparation method of the corrugated plate is: prepreg the carbon fiber resin matrix composite material according to [45 / 0 / -45 / 90] s Layers were laid in a manner, and kept at 150° C. for 30 minutes to obtain a corrugated board; the wall thickness of the corrugated board was 1 mm. The corrugated plate was cut into a preset size by a CNC machine tool, with a length of 78 mm and a height of 21 mm.

[0050] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com