Welding power supplies and user interfaces for welding power supplies

An interface and electric power technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as inability to produce weld seams, insufficient arc action to produce weld seams, and difficulty in adjusting welding parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

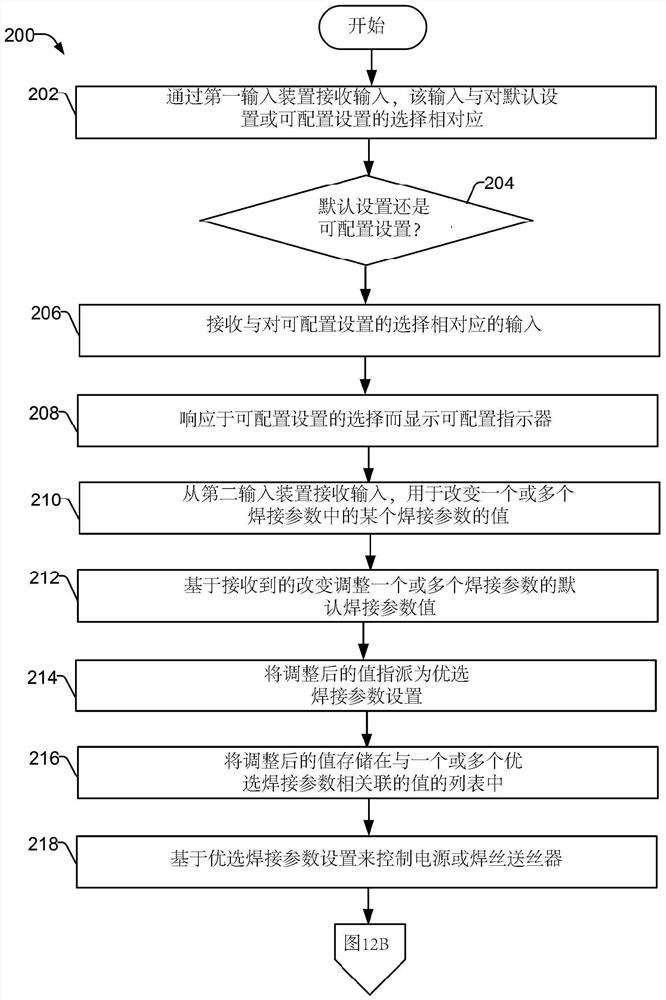

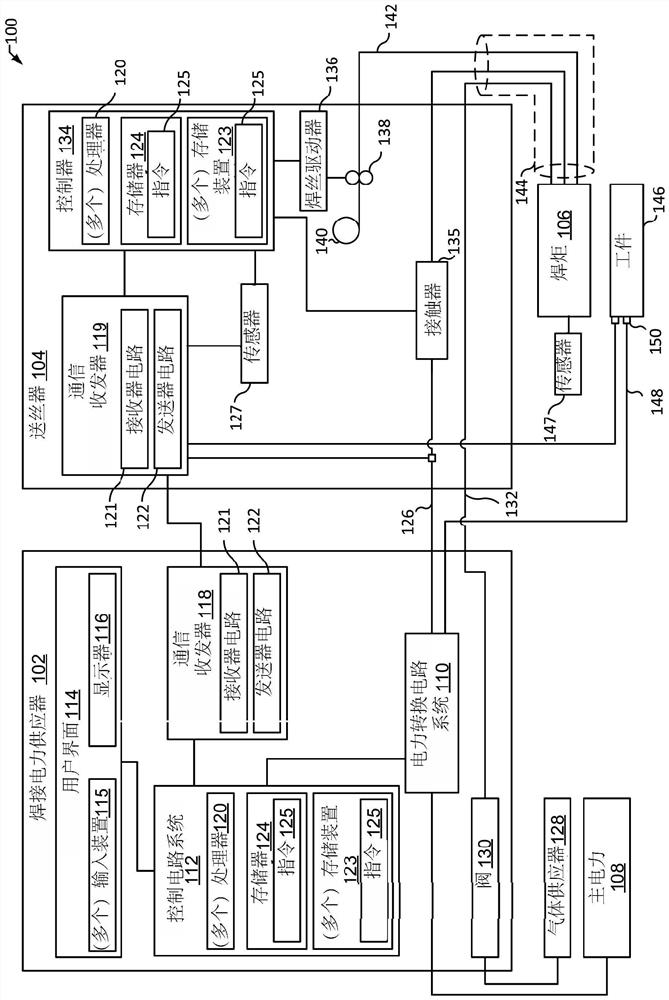

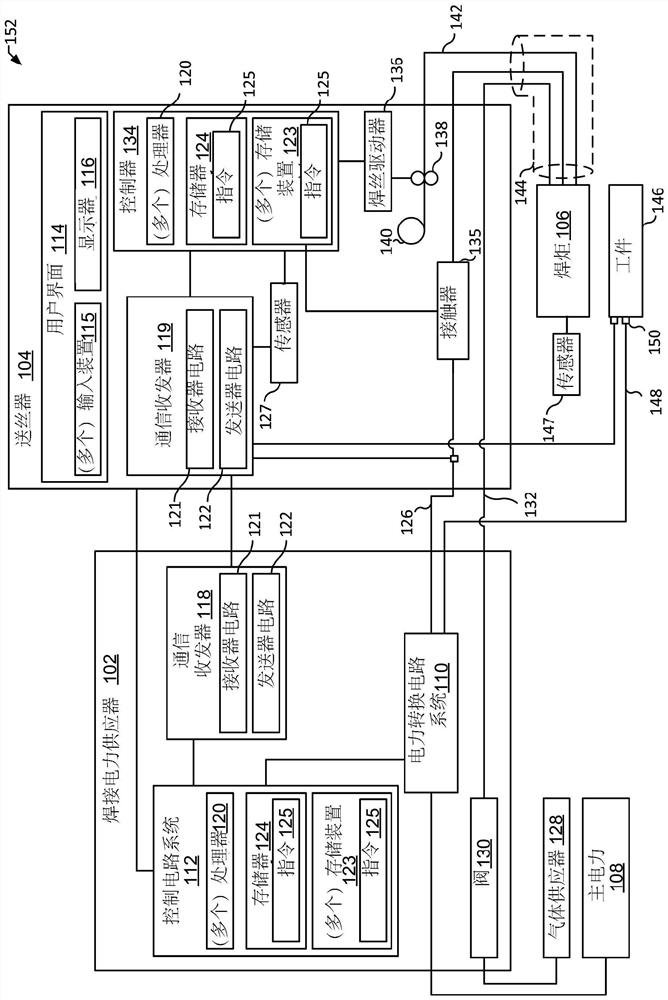

[0017] The disclosed example power supplies, user interfaces, and methods allow simple and intuitive setup of configurable and / or default settings for a welding power supply and / or wire feeder.

[0018] In some examples, the welding system includes a power supply for controlling the welding based on one or more welding parameters (e.g., voltage, current, power, wire feed speed, gas flow rate, pulse rate, workpiece thickness, workpiece material type, electrode type, welding process , travel speed, arc length or joint type, etc.) to deliver power to the torch. As disclosed herein, welding parameters may correspond to default and / or factory settings that represent empirically cited values for a particular welding process (e.g., based on material type, electrode diameter, welding process, and / or tools, etc.). Welding parameters can be configured for specific purposes. In other words, an interface (such as an auto-set button) may be provided to allow an operator to adjust one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com