Drilling equipment used in wood processing

A technology of processing and drilling equipment, applied to wood processing equipment, drilling machines supported by operators, manufacturing tools, etc., can solve the problems of drill stuck, damage the hole wall, increase costs, etc., and achieve good anti-seize effect , Prevent the generation of impact force and improve the impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples or drawings are used to illustrate the present invention, but not to limit the scope of the present invention.

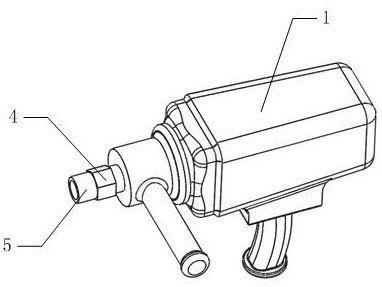

[0037] The rotating shaft of the impact drill body 2 of the present invention can output pure rotary motion, and can also output rotary and impact motion, and the frequency of rotation and impact motion has a certain ratio.

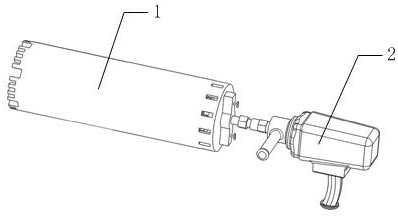

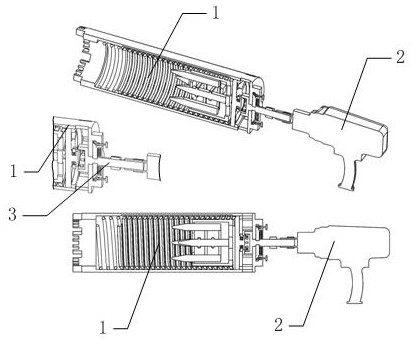

[0038] Such as figure 1 ,2 As shown, it includes a drill cylinder module 1 and a hammer drill body 2, wherein the drill cylinder module 1 is detachably mounted on the output shaft 5 of the hammer drill body 2; it is characterized in that: the drill cylinder module 1 includes a connecting shaft 3, a drill Tube 12, clamping block 13, connecting slide block 11, impact block 15, screw driving structure 16, wherein such as Figure 4 As shown, the connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com