Inorganic composite fiber blanket and preparation method thereof

An inorganic composite and fiber blanket technology, applied in the direction of chemical instruments and methods, layered products, ceramic layered products, etc., can solve the problems of fiber cotton block gaps, module integrity deterioration, etc., to achieve good integrity and good mutual Effects and conditions that are easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention also provides a preparation method of the inorganic composite fiber blanket described in the technical solution, comprising the following steps:

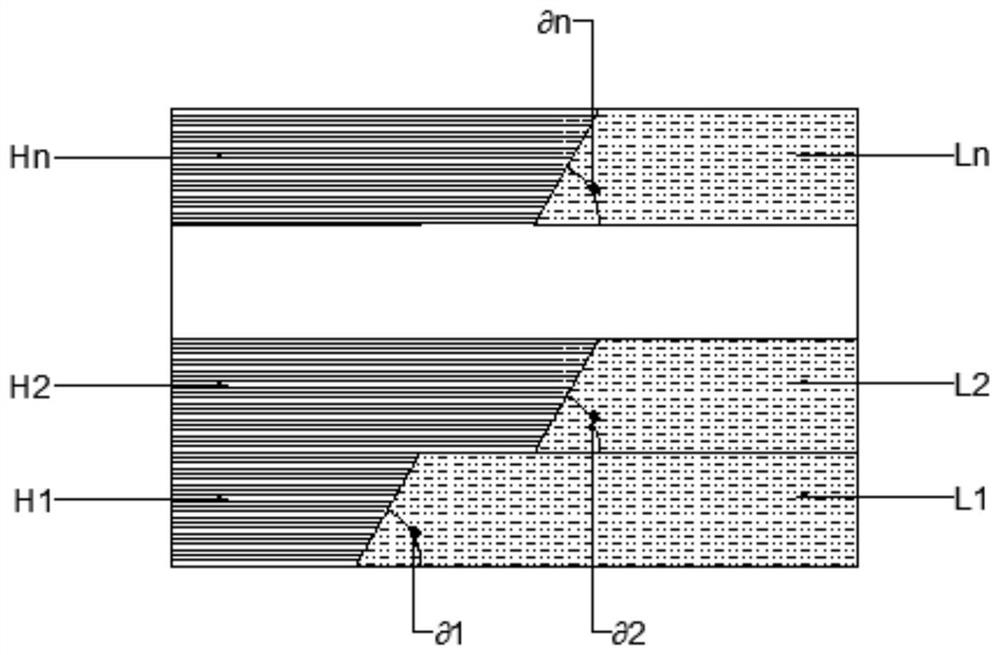

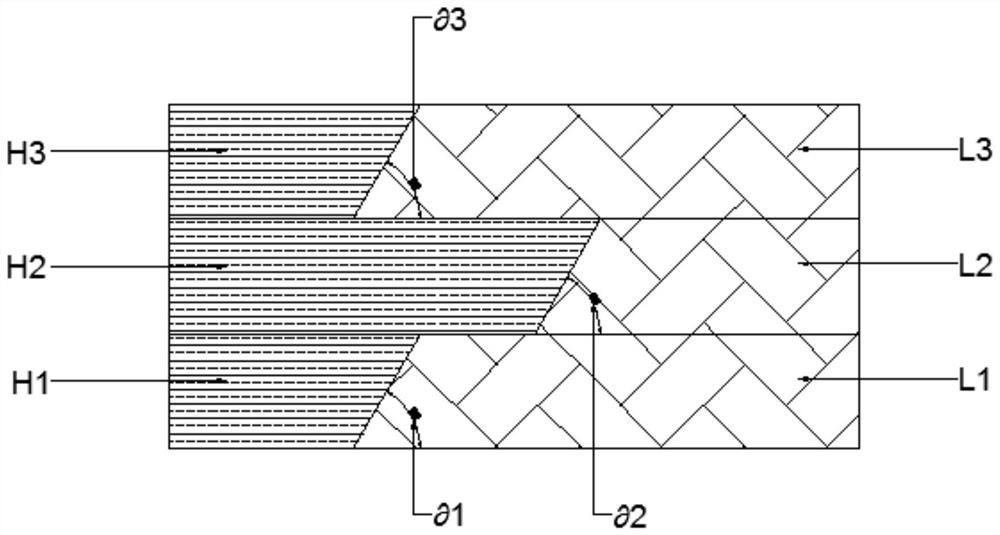

[0042] a) horizontally splicing the fiber cotton blanks on the high temperature side and the fiber cotton blanks on the back temperature side layer by layer to form multiple layers of cotton blanks;

[0043] b) Composite the multi-layer cotton base layers obtained in step a) to obtain an inorganic composite fiber blanket.

[0044] In the present invention, firstly, the fiber cotton blanks on the high temperature side and the fiber blank blanks on the back temperature side are spliced in the horizontal direction layer by layer to form multiple layers of cotton blanks. In the present invention, the fiber blanks on the high temperature side and the fiber blanks on the back temperature side are the same as those in the above technical solution, and will not be repeated here.

[0045] In a preferred embodi...

Embodiment 1

[0059] A method for preparing an inorganic fiber composite blanket for an inorganic fiber composite module used in a high-temperature kiln at 1280°C. The overall thickness of the module is 300mm, and the bulk density is 180kg / m 3 . The fibers on the high temperature side are alumina fibers, and the fibers on the back temperature side are zirconium-containing ceramic fibers.

[0060] (1) Determination of the specifications and dimensions of the composite cotton base layer:

[0061] According to the service temperature of the inorganic composite fiber module prepared according to the requirements, the thickness of the inorganic fiber blanket to be prepared is determined to be 25mm, and the surface density is 2.4kg / m 3 According to the specifications of the above-mentioned inorganic composite fiber blanket, the optimal number of composite layers is 3, and the width of the inorganic fiber blank at the high temperature side: H1 = 80mm, H2 = 130mm, H3 = 80mm; according to the size ...

Embodiment 2

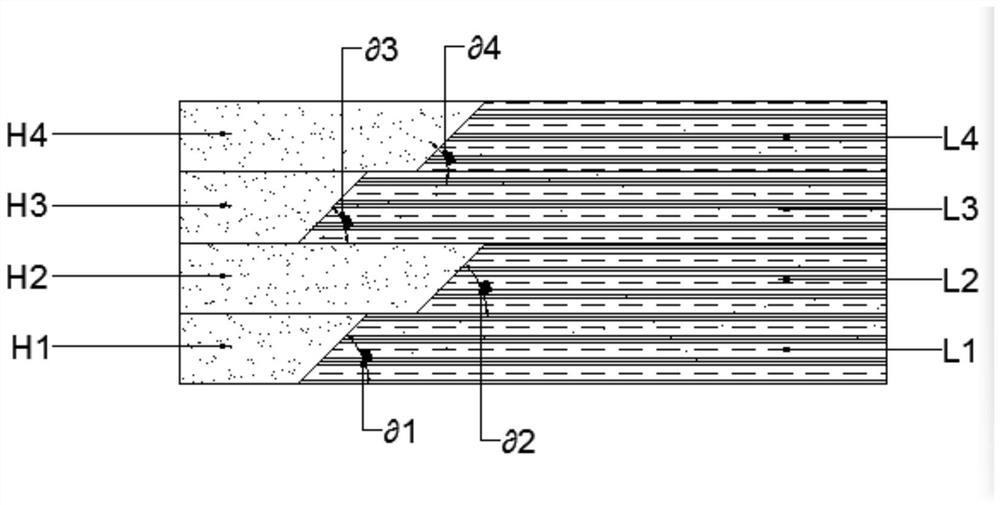

[0076] A method for preparing an inorganic fiber composite blanket for an inorganic fiber composite module that meets the requirements of a high-temperature kiln at 1210°C. The overall thickness of the module is 300mm, and the bulk density is 200kg / m 3 . Zirconium-containing ceramic fibers are used for the fibers on the high-temperature side, and high-alumina ceramic fibers are used for the fibers on the back-temperature side.

[0077] (1) Determination of the specifications and dimensions of the composite cotton base layer:

[0078]According to the service temperature of the inorganic composite fiber module prepared according to the requirements, the thickness of the inorganic fiber blanket to be prepared is determined to be 25mm, and the surface density is 3.2kg / m 2 According to the specifications of the above-mentioned inorganic composite fiber blanket, the optimal number of composite layers is determined to be 4, and the width of the inorganic fiber blank at the high temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com