Slitting and tape breaking device for die cutting of self-adhesive labels

A strip-cutting and strip-breaking technology, which is applied in the directions of winding strips, transporting and packaging, and sending objects, can solve the problems of low processing efficiency, inconvenient adjustment, and single function, so as to improve work efficiency and multi-functionality , the effect of improving practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

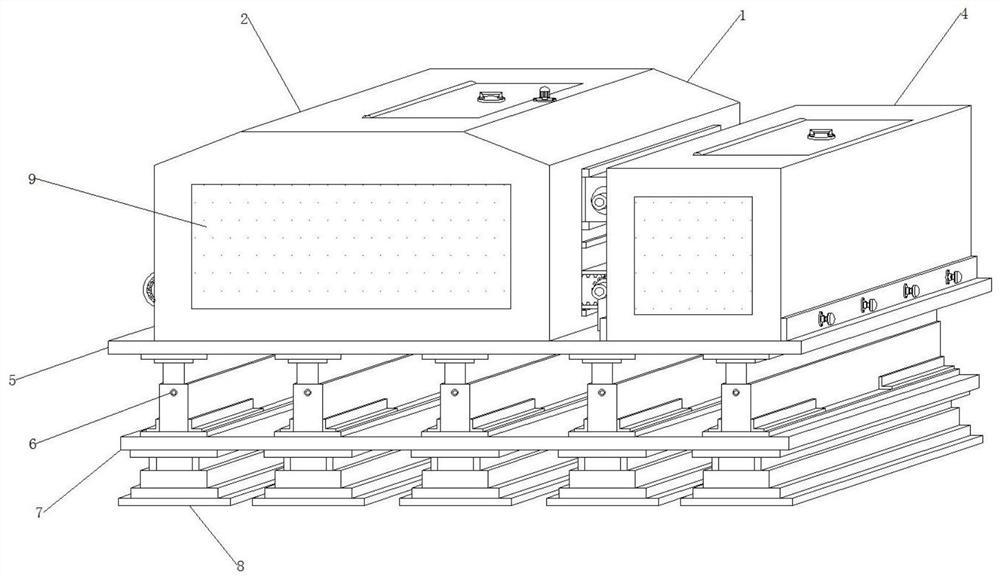

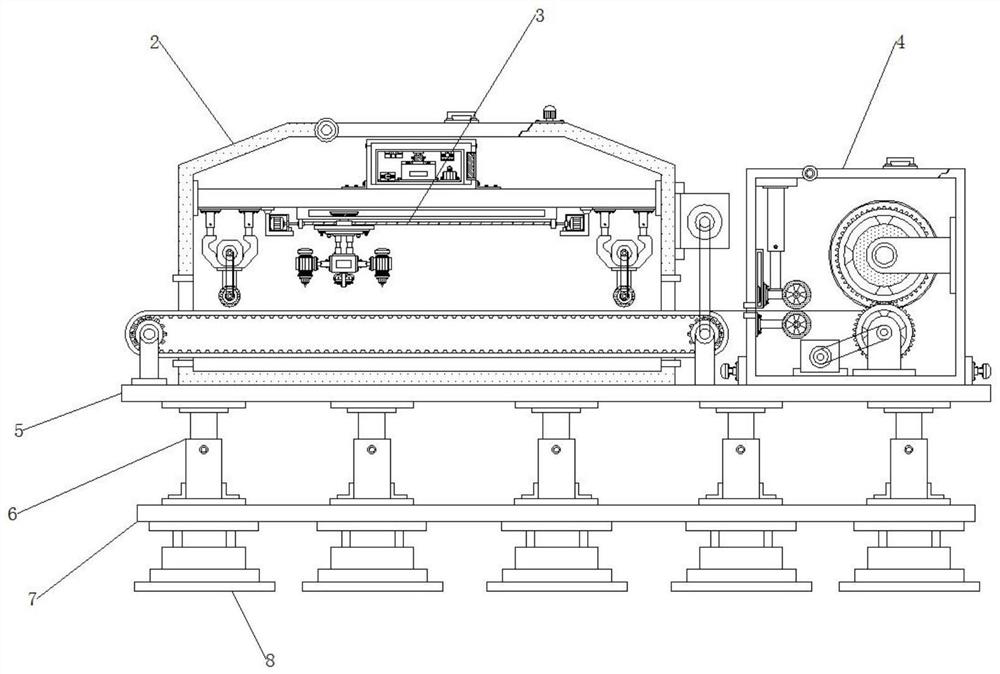

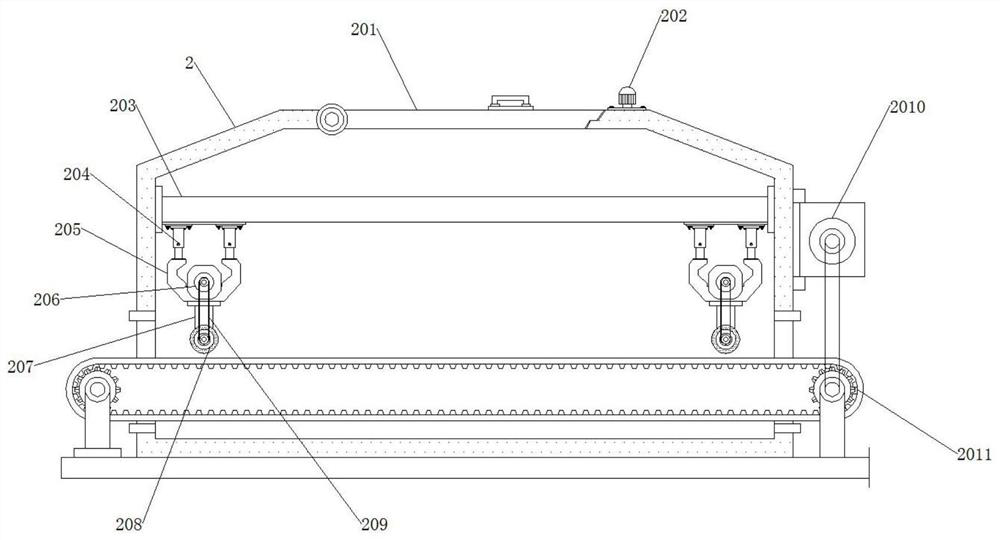

[0032] Embodiment one, with reference to Figure 1-5 , the present invention provides a technical solution: a stripping and breaking device for self-adhesive label die-cutting, including a stripping and breaking device main body 1, a striping mechanism 2, a stripping mechanism 3 and a collection mechanism 4, the stripping One side of the main body 1 of the strip breaking device is embedded with a slitting mechanism 2, the other side of the main body 1 of the strip breaking device 1 is embedded and connected with a collection mechanism 4, and the bottom end of the main body 1 of the strip breaking device 1 is embedded and connected with a mounting plate 5 The bottom end of the mounting plate 5 is embedded with a hydraulic expansion plate 6, the bottom end of the hydraulic expansion plate 6 is embedded with a fixed base 7, and the bottom end of the fixed base 7 is embedded with a non-slip pad 8;

[0033] The inner middle part of the slitting mechanism 2 is embedded with a broken...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com