Titanium-niobium-oxygen alloy with negative thermal expansion and preparation method thereof

A negative thermal expansion and alloy technology, which is applied in the field of negative thermal expansion titanium niobium oxygen alloy and its preparation, can solve the problems of low negative thermal expansion coefficient of titanium alloy, insufficient temperature range, narrow adjustable range, etc., and achieve stable shape memory effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] With high purity Ti, Nb and TiO 2 The powder is used as a raw material to prepare an alloy, and the weight of each component is: Ti: 65.900g; Nb: 34.100g; the weight percentage of each alloy element is: Nb: 34.1wt%; O: 0wt%, and the balance is Ti. The prepared raw materials are placed in a magnetically stirred vacuum non-consumable electric arc furnace for five times of repeated melting to obtain an ingot with uniform composition. The ingot was hot-forged into a bar at 1000°C with a deformation of 75%. After solution treatment at 900°C for 40 minutes, put it into water for quenching and cooling. Turning removes the scale on the surface of the bar, and then carries out cold rolling deformation with a deformation amount of 93% at room temperature.

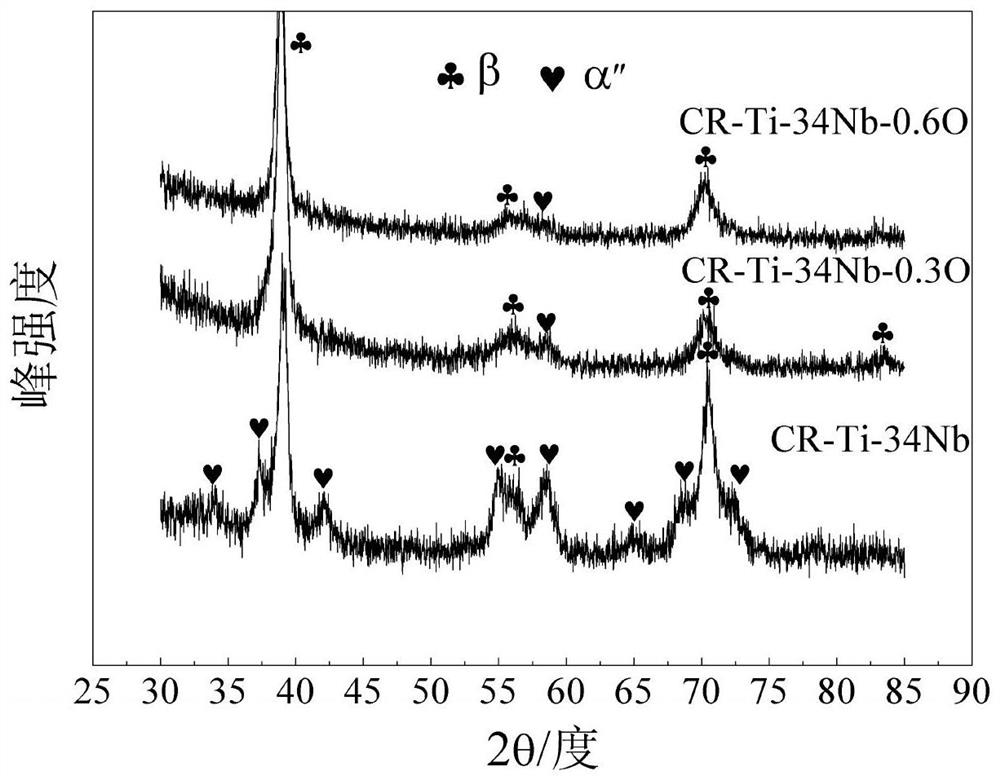

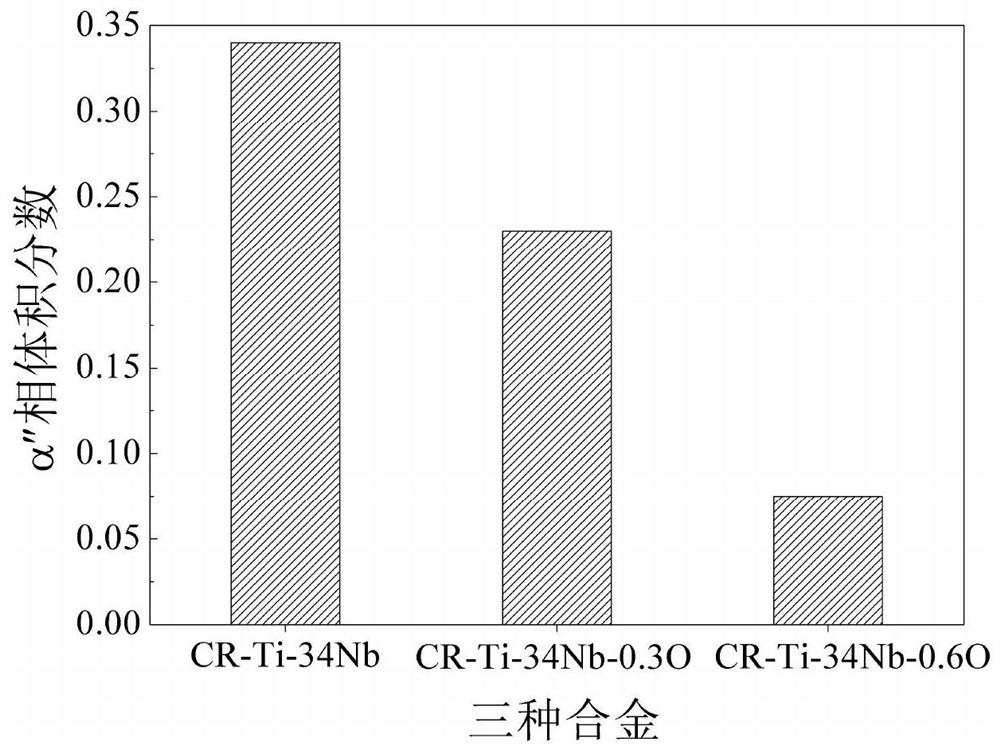

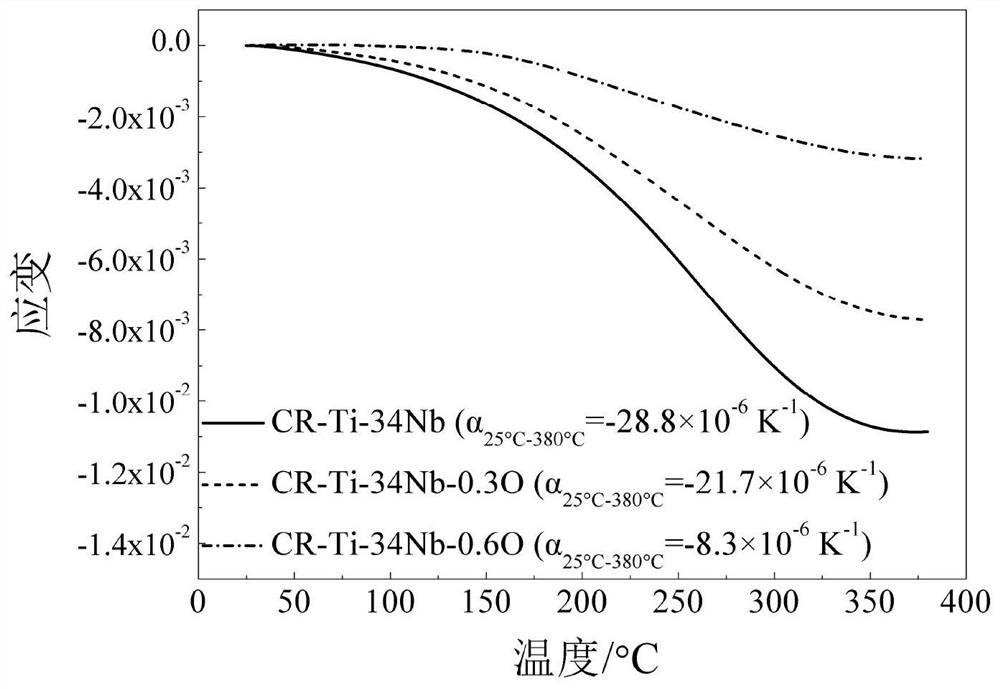

[0028] After the above treatment, the obtained alloy is subjected to XRD analysis, and the spectrum is as follows figure 1 As shown, according to the figure, it can be seen that the phase composition is β matrix + a small a...

Embodiment 2

[0031] With high purity Ti, Nb and TiO 2 Powder is used as raw material to prepare alloy, and the weight of each component is: Ti: 65.150g; Nb: 34.100g; TiO 2 : 0.750g; the weight percent of each alloy element is: Nb: 34.1wt%; O: 0.3wt%, and the balance is Ti. The prepared raw materials are placed in a magnetically stirred vacuum non-consumable electric arc furnace for five times of repeated melting to obtain an ingot with uniform composition. The ingot was hot forged into a bar at 900°C with a deformation of 80%. After solid solution treatment at 850°C for 60 minutes, put it into water for quenching and cooling. Turning removes the scale on the surface of the bar, and then carries out cold rolling deformation with a deformation amount of 95% at room temperature.

[0032] After the above treatment, the obtained alloy is subjected to XRD analysis, and the spectrum is as followsfigure 1 As shown, according to the figure, it can be seen that the phase composition is β matrix +...

Embodiment 3

[0034] With high purity Ti, Nb and TiO 2 Powder is used as raw material to prepare alloy, and the weight of each component is: Ti: 64.500g; Nb: 34.000g; TiO 2 : 1.500g; the weight percent of each alloy element is: Nb: 34.0wt%; O: 0.6wt%, and the balance is Ti. The prepared raw materials are placed in a magnetically stirred vacuum non-consumable electric arc furnace for five times of repeated melting to obtain an ingot with uniform composition. The ingot was hot forged into a bar at 950°C with a deformation of 70%. After solution treatment at 950°C for 30 minutes, put it into water for quenching and cooling. Turning removes the scale on the surface of the bar, and then carries out cold rolling deformation with a deformation amount of 92% at room temperature.

[0035] After the above treatment, the obtained alloy is subjected to XRD analysis, and the spectrum is as follows figure 1 As shown, according to the figure, it can be seen that the phase composition is β matrix + a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average expansion coefficient | aaaaa | aaaaa |

| Average expansion coefficient | aaaaa | aaaaa |

| Average expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com