Automatic pressure-disengaging machine for aluminum electrolysis anode scrap carbon block and carbon block pressure-disengaging method

A technology of anode anode pressing and off-line, which is applied in the field of equipment for automatic detachment of anode anode carbon blocks, which can solve the problems of high labor intensity, complex equipment structure, and high manufacturing cost, and achieve low construction and maintenance costs and simple methods High efficiency and good pressure release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

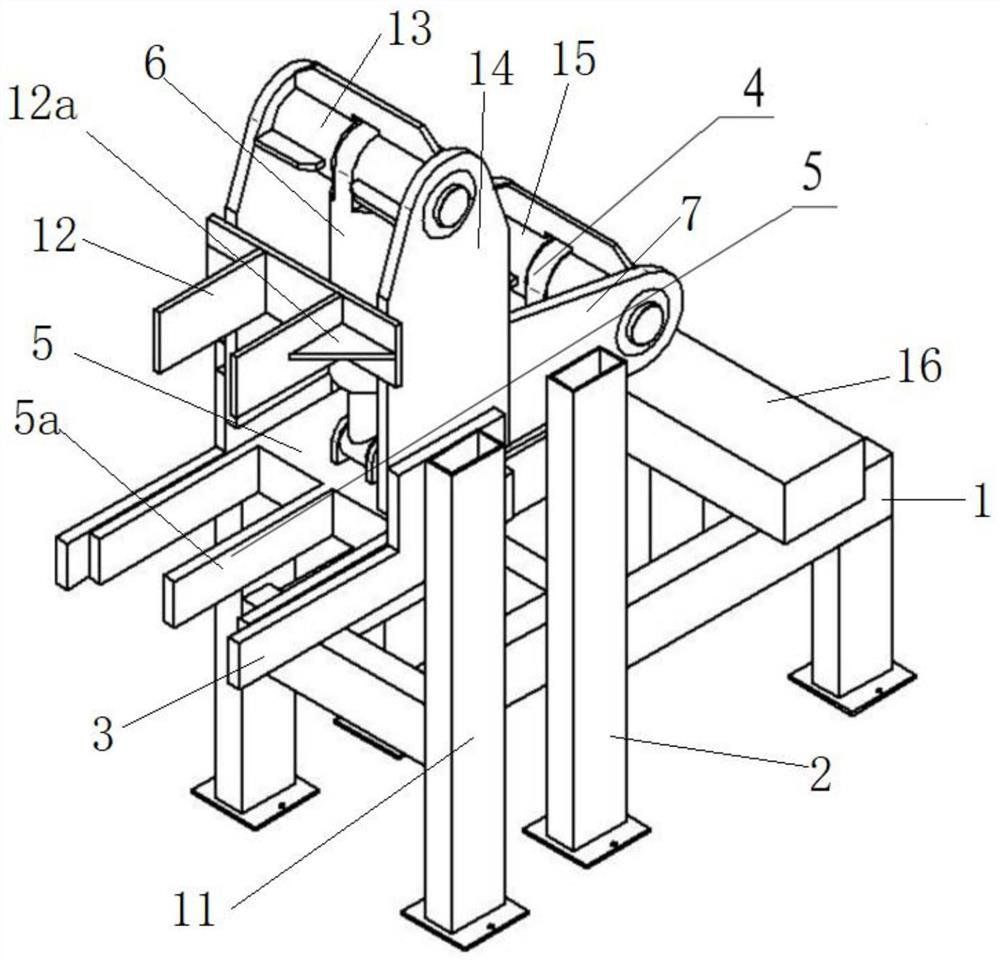

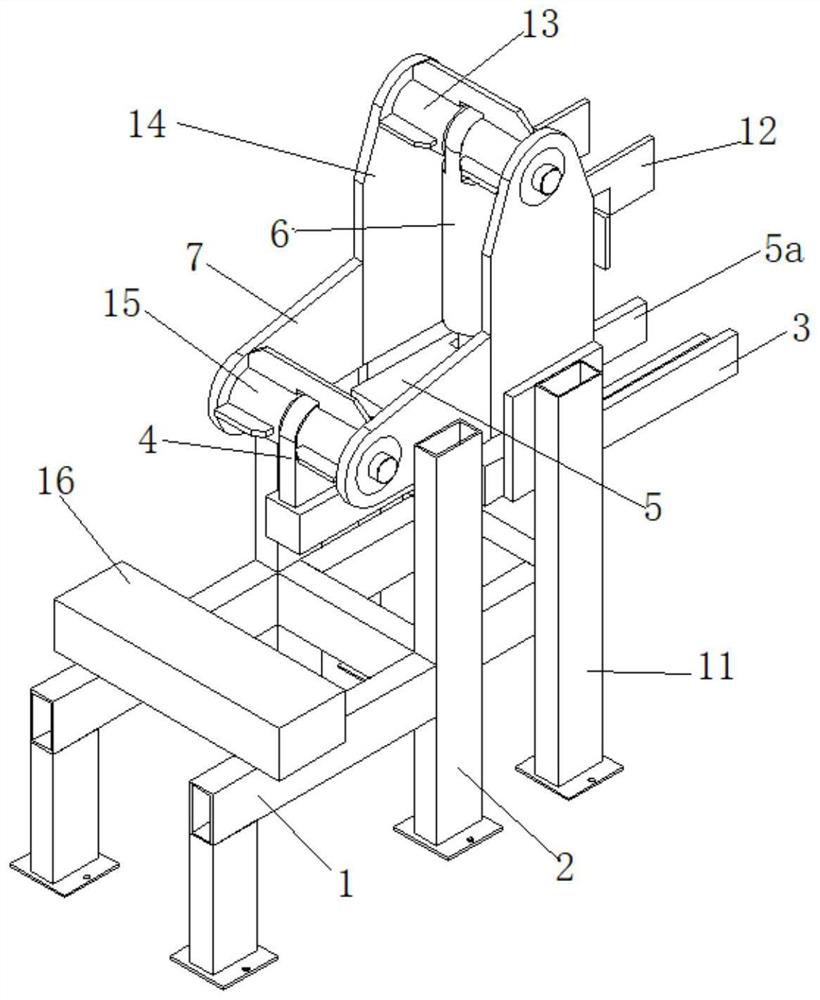

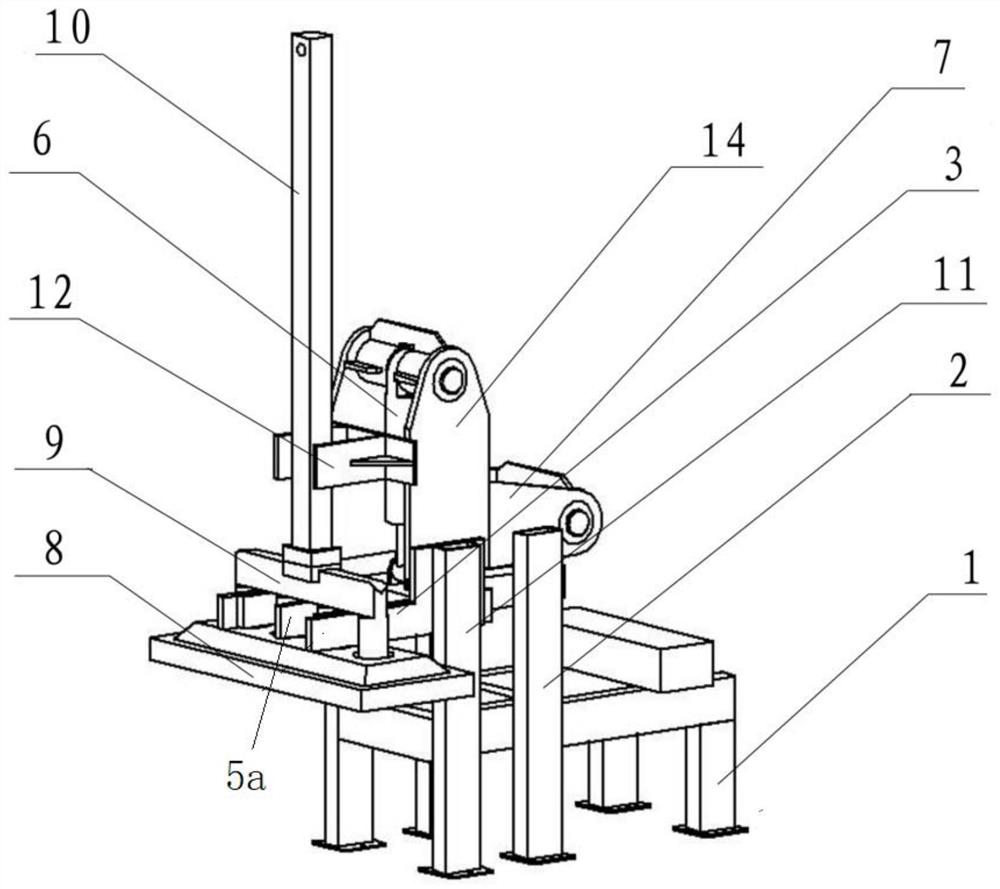

[0016] Such as figure 1 , figure 2 The shown aluminum electrolytic anode anode automatic crushing machine includes a frame 1 welded with steel, a front column 11 symmetrically arranged on both sides of the front end of the frame, a rear column 2 symmetrically arranged on both sides of the middle of the frame, and symmetrically installed on both sides of the frame. Two steel claw hangers protruding forward from the inner side of the front column 3, a press-off knife that can move back and forth and up and down between the two steel claw hangers, 5, symmetrically installed on the inside of the two steel claw hangers Two press-off oil cylinder support plates 14 extending upward, the press-off oil cylinder 6 installed between the two press-off oil cylinder support plates, the guide rod fixing device 12 welded to the front ends of the two press-off oil cylinder support plates, symmetrically installed on the rear Two pressure-off knife positioning oil cylinder support plates 7 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com