Weak expansive soil roadbed construction process

A construction process and weak expansion technology, which is applied in the field of weak expansion soil subgrade construction technology to achieve the effect of reducing the possibility of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

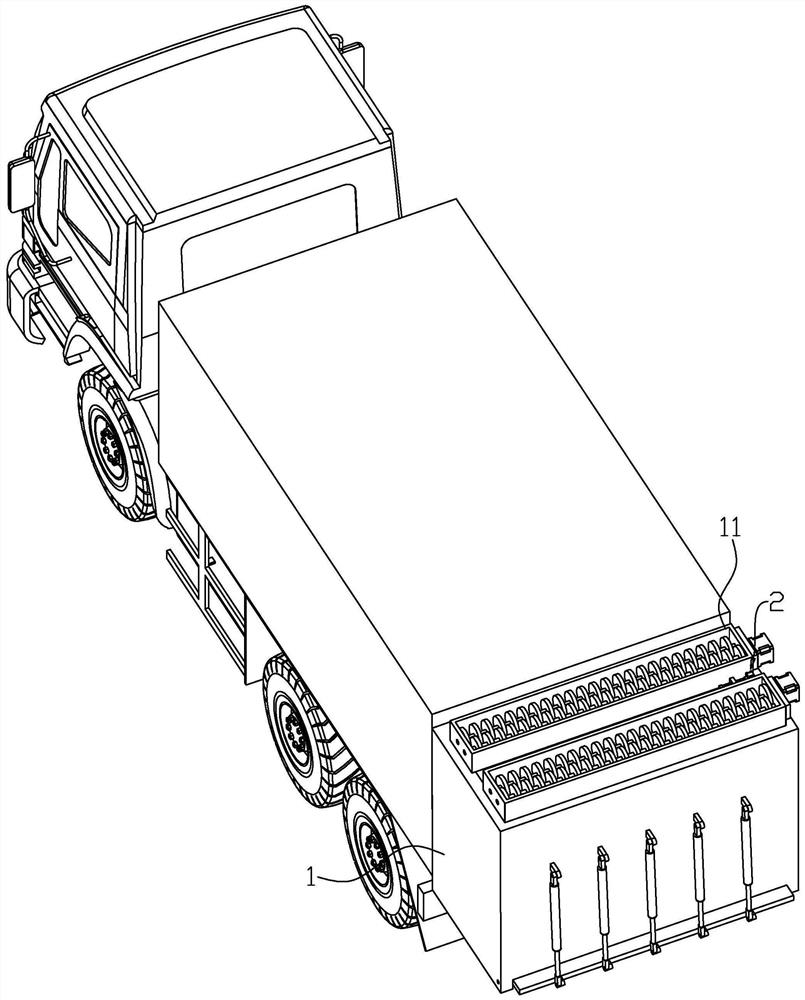

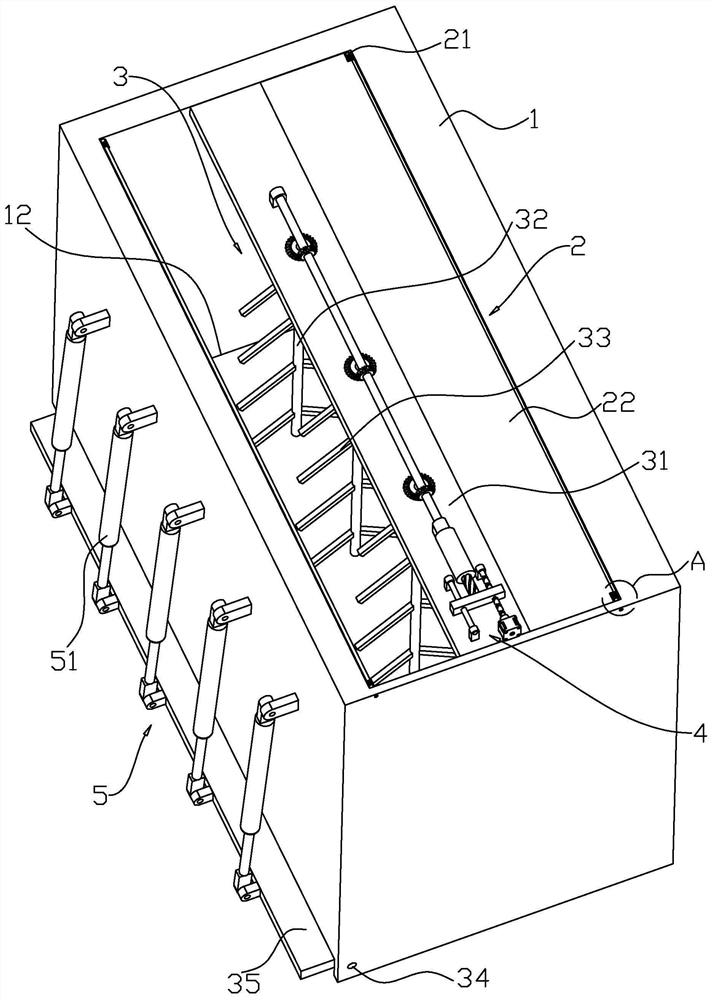

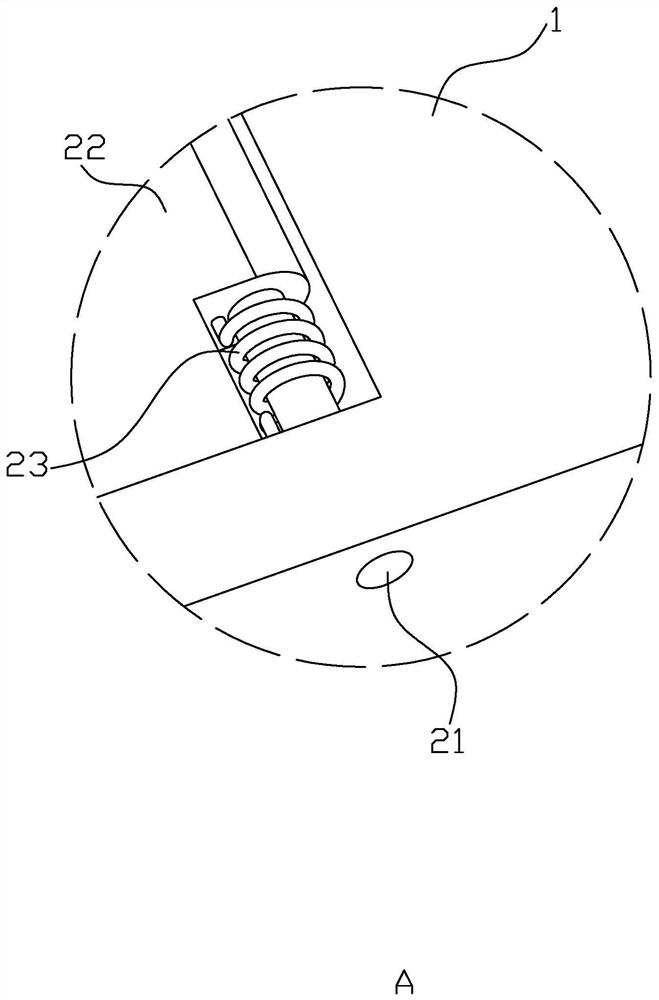

[0038] The following is attached Figure 1-5 The application is described in further detail.

[0039] The embodiment of the present application discloses a weak expansive soil embankment construction process, including the following steps: S1, processing the weak expansive soil layer: first draw two road lines, and then excavate the weak expansive soil between the two road lines with an excavator to the mixing bin 1, then add lime or cement into the mixing bin 1, then use the stirring device 3 to mix the weak expansive soil and lime evenly, and then discharge the mixture of weak expansive soil and lime to the two road lines , then level and roll the mixture of weak expansive soil and lime;

[0040] S2, paving and leveling plain soil on the upper surface of the weak expansive soil layer;

[0041] S3, draw a neat standard area grid on the lower bearing layer of step 2, and manually spread the cement evenly in each grid by the amount of cement per square meter;

[0042] S4, ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com