Electronic thermostat control system

A control system and thermostat technology, applied in the control of coolant flow, machine/engine, engine cooling, etc., can solve the problem that the electronic thermostat has no detection and feedback, and the electronic thermostat has no feedback mechanism for temperature and stroke. , Unfavorable ECU stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Examples such as Figure 8 As shown, an electronic thermostat includes an output drive shaft 1, a heating wax bag 2 is installed on the output drive shaft 1, a heating resistance wire 3 is installed in the heating wax bag 2, a magnet 4 is installed on the output drive shaft 1, and the magnet 4, a magnetic field strength detection chip 5 is installed on one side.

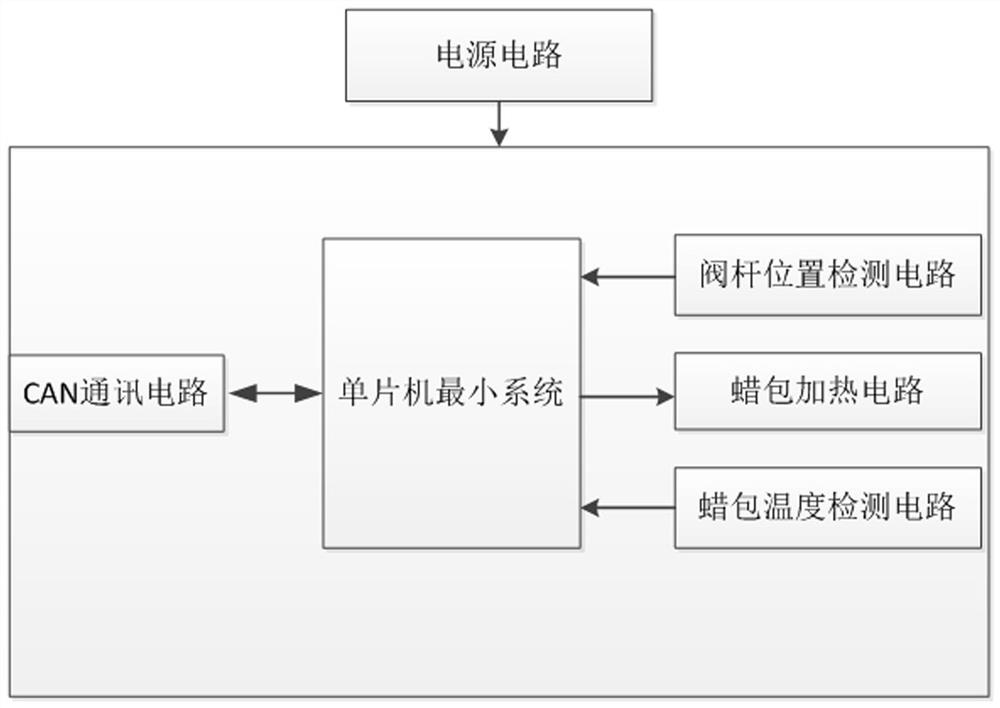

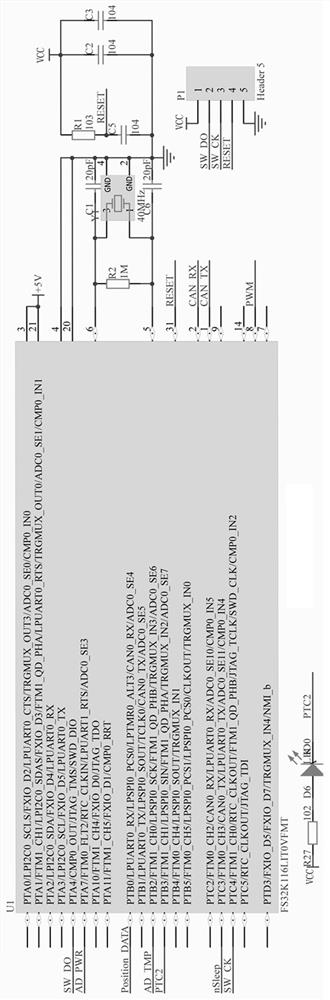

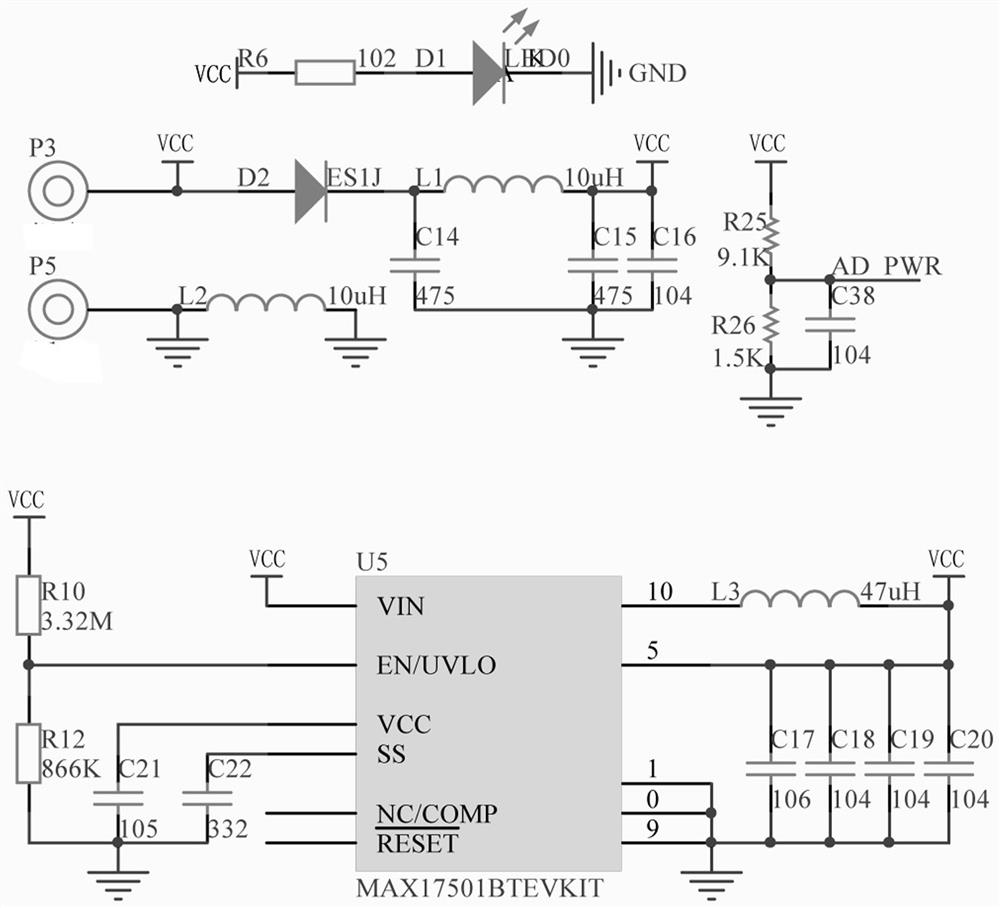

[0026] Such as figure 1 As shown, a control system of an electronic thermostat includes a minimum system of a single chip microcomputer, a CAN communication circuit, a power supply circuit, a valve stem position detection circuit, a wax bag temperature detection circuit and a wax bag heating circuit, a CAN communication circuit, and a valve stem position detection circuit The wax bag temperature detection circuit and the wax bag heating circuit are connected to the minimum system of the single chip microcomputer, the power supply circuit is connected to the minimum system of the single chip microcomputer, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com