Double-flap-valve discharging structure for cyclone of spray dryer

A technology of spray dryer and flap valve, which is applied in the direction of lifting valve, valve detail, conveyor, etc., can solve the problems of fan stuck, unable to close tightly, butterfly valve blocked, etc., and achieves easy operation, high degree of automation, Good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

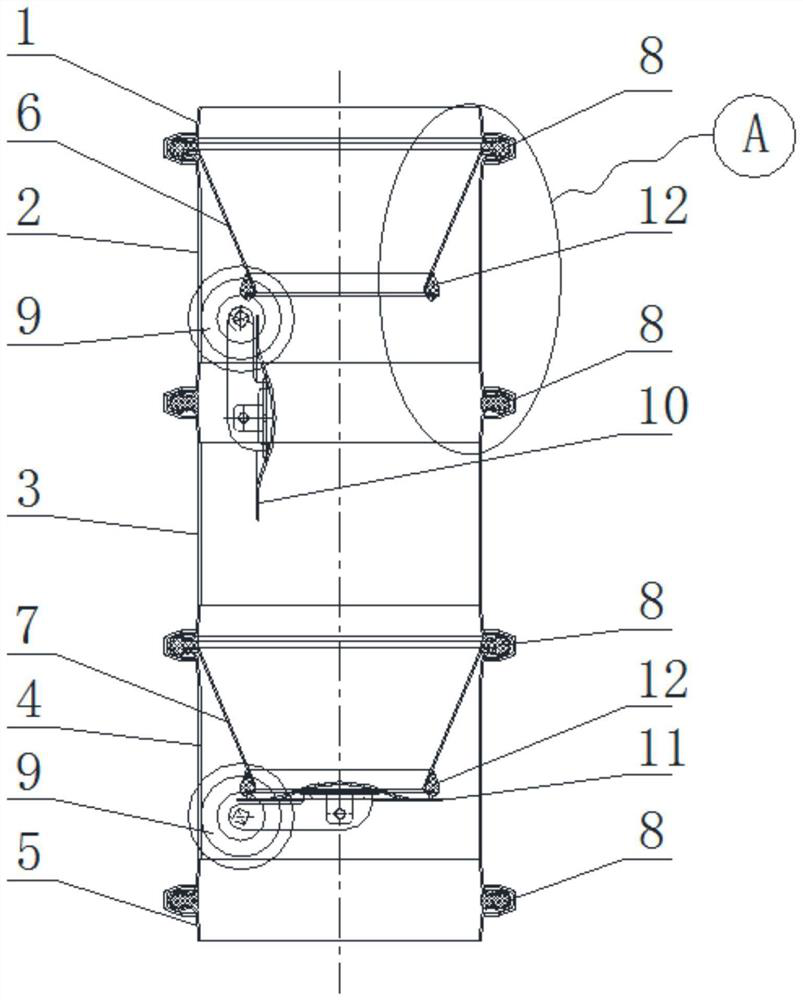

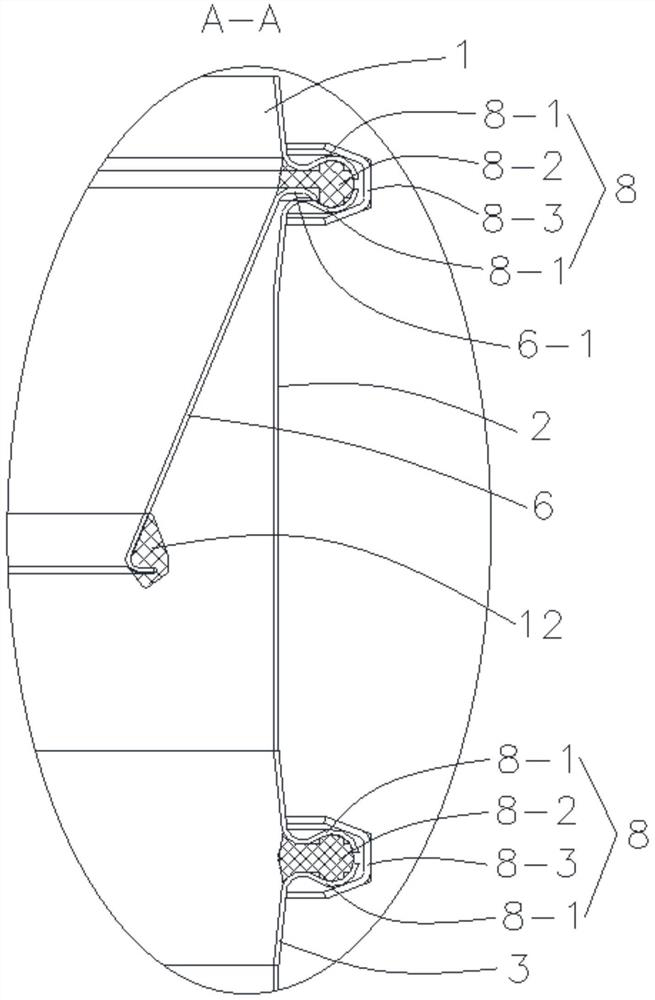

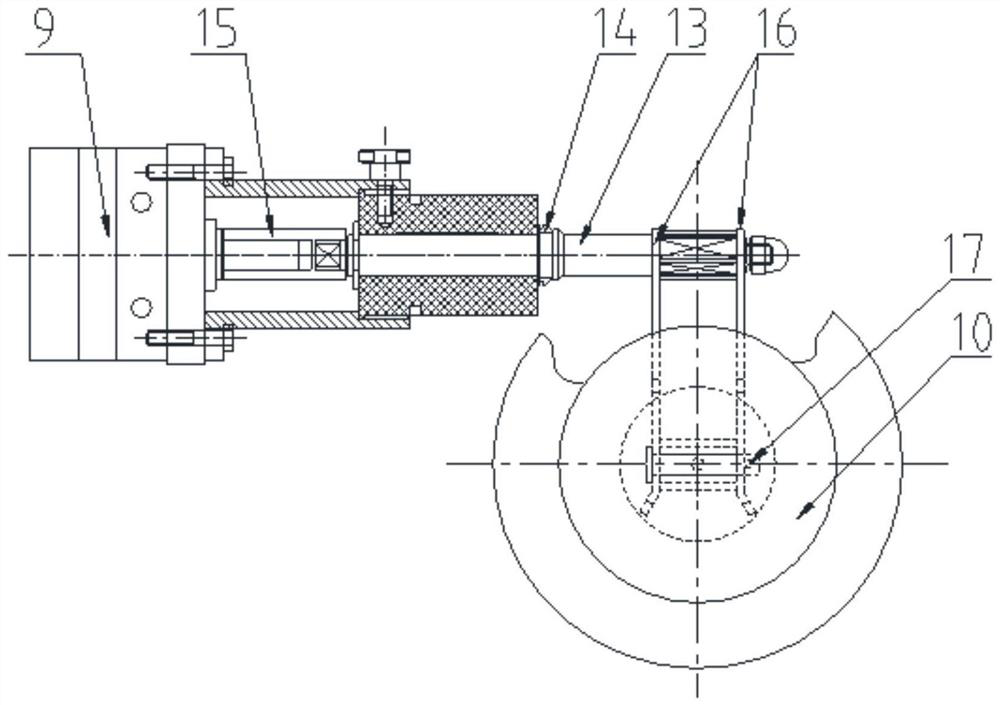

[0019] Such as Figure 1~3 As shown, a double flap valve discharge structure for the spray dryer cyclone, including the upper end 1, the first cylinder 2, the second cylinder 3, the third cylinder 4 and the The lower end 5, between the upper end 1 and the first cylinder 2, between the first cylinder 2 and the second cylinder 3, between the second cylinder 3 and the third cylinder 4, and the third cylinder Both the body 4 and the lower end 5 are fixedly connected by a sealing connector 8, an upper cone bucket 6 is arranged inside the first cylinder body 2, a lower cone bucket 7 is arranged inside the third cylinder body 4, and the upper end The head 1, the upper cone 6, the first cylinder 2, the second cylinder 3, the lower cone 7, the third cylinder 4 and the lower end 5 are connected in sequence, and the upper cone 6 and the lower cone 7 The direction of the material is consistent, and its big end is set upward, which is convenient for material collection and improves the ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com