Dual-fuel combustor with graded ignition, graded air distribution and flue gas recirculation, and boiler

A technology of flue gas recirculation and graded air distribution, applied in burners, lighting and heating equipment, etc., can solve the problems of unsatisfactory low-nitrogen combustion effect and poor operation safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

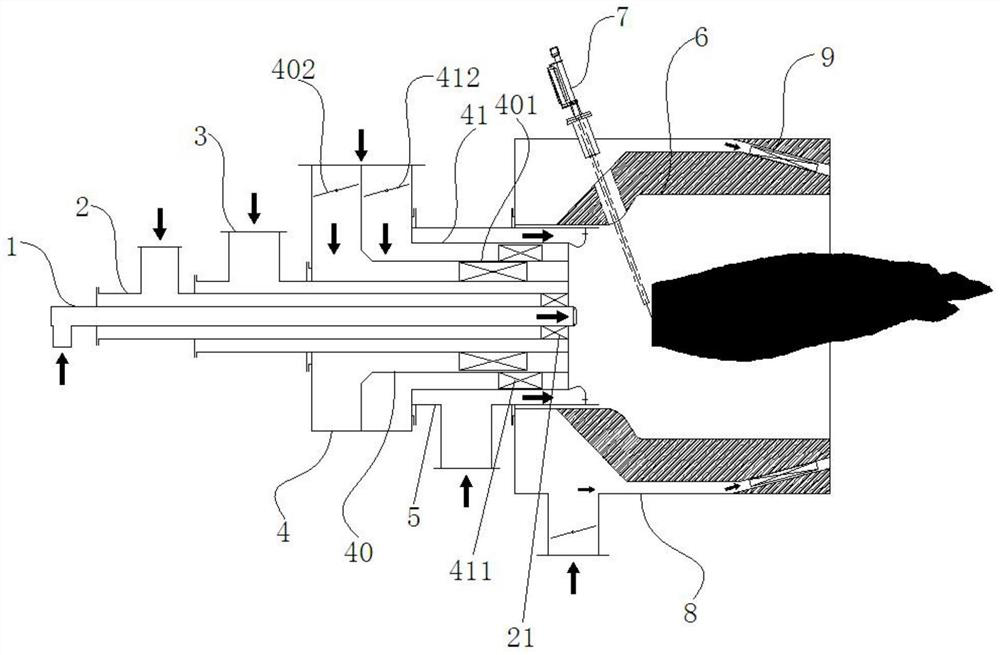

[0026] refer to figure 1 , the staged ignition and staged air distribution of this embodiment adopts a dual-fuel burner with flue gas recirculation, including an ignition gas pipe 1, a central air pipe 2, a primary air chamber 3, a secondary air chamber 4, a main combustion chamber 5, and a preheating chamber. Combustion chamber 6, ignition gun 7, circulating air chamber 8, the central air pipe 2 is set outside the ignition gas pipe 1, the primary air chamber 3 is set outside the central air pipe 2, the secondary air Chamber 4 is set outside the primary air chamber 3, the main combustion chamber 5 is set outside the secondary air chamber 4, the central air duct 2, primary air chamber 3, secondary air chamber 4 air outlets and ignition The gas pipe 1 and the gas outlet of the main combustion chamber 5 are located inside the pre-combustion chamber 6 , the ignition gun 7 is installed on the pre-combustion chamber 6 , and the circulating air chamber 8 is arranged outside the pre-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com