Steam recovery heat exchange unit for aerated concrete industry

A technology of aerated concrete and heat exchange unit, which is applied to indirect heat exchangers, heat exchanger types, lighting and heating equipment, etc. Efficiency compensation, reduction of guiding energy consumption, and improvement of steam activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

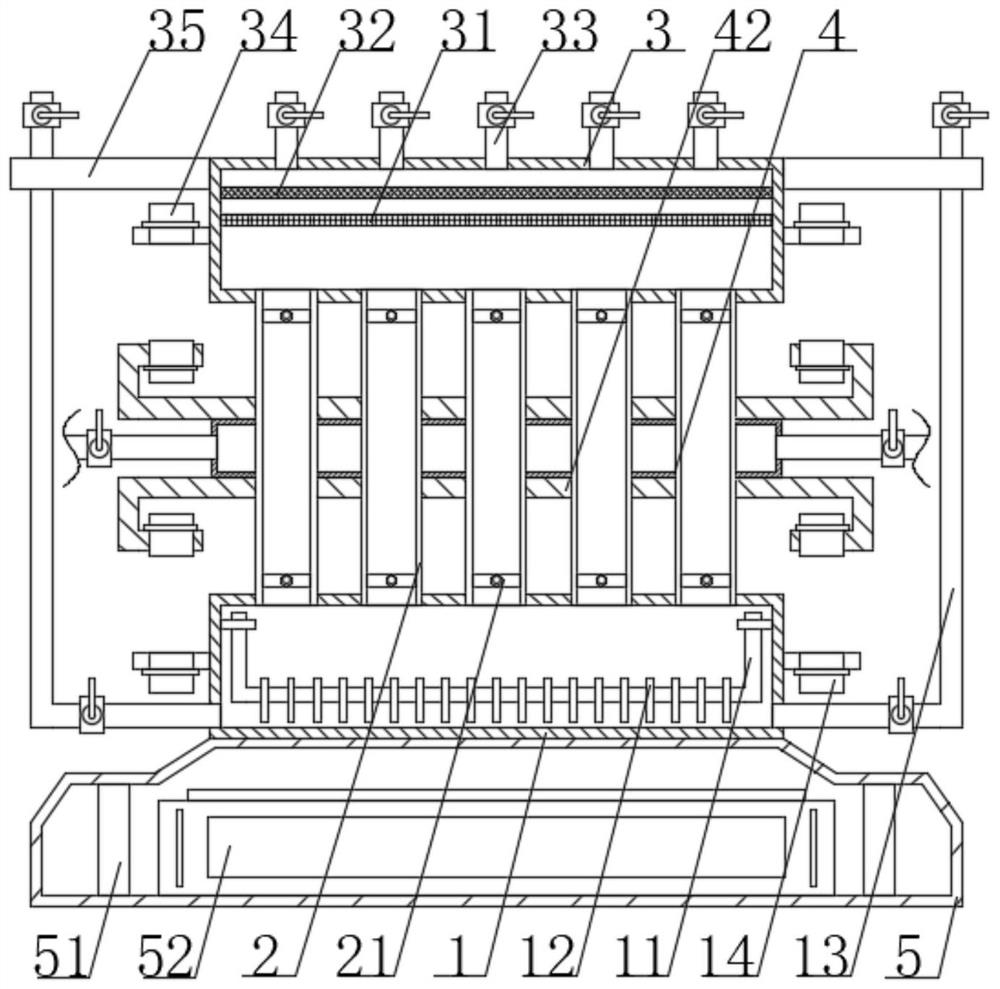

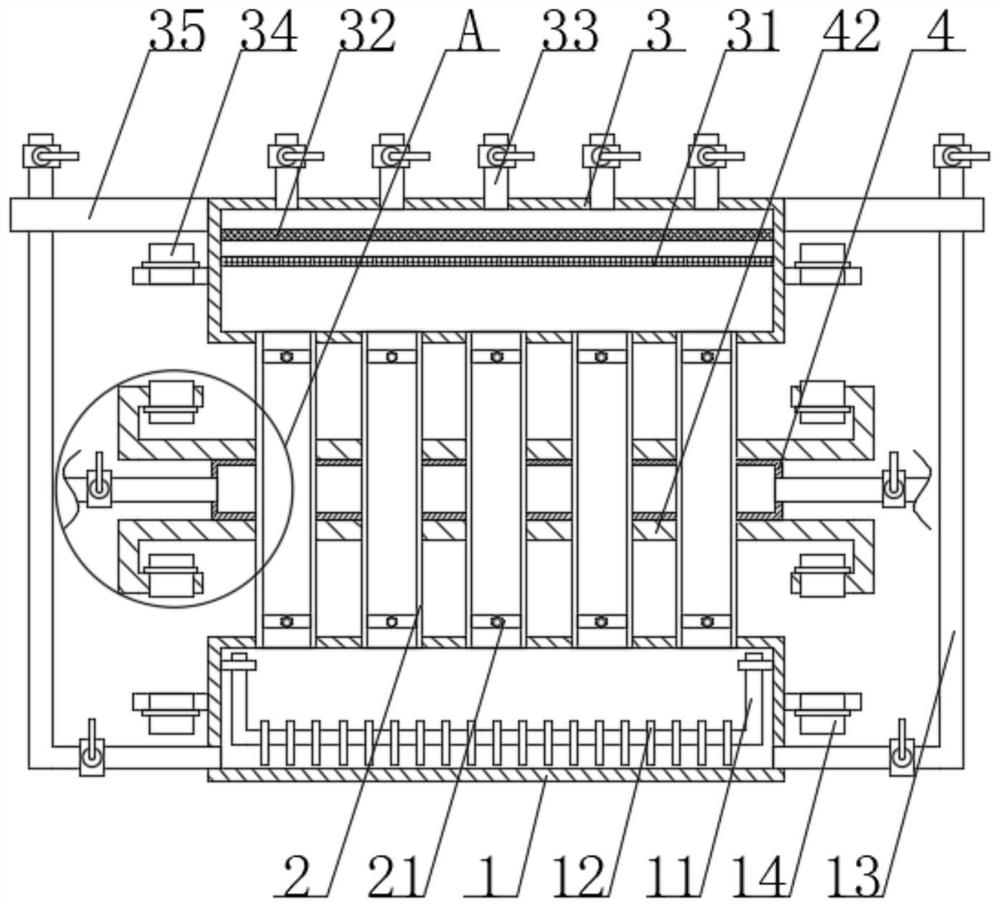

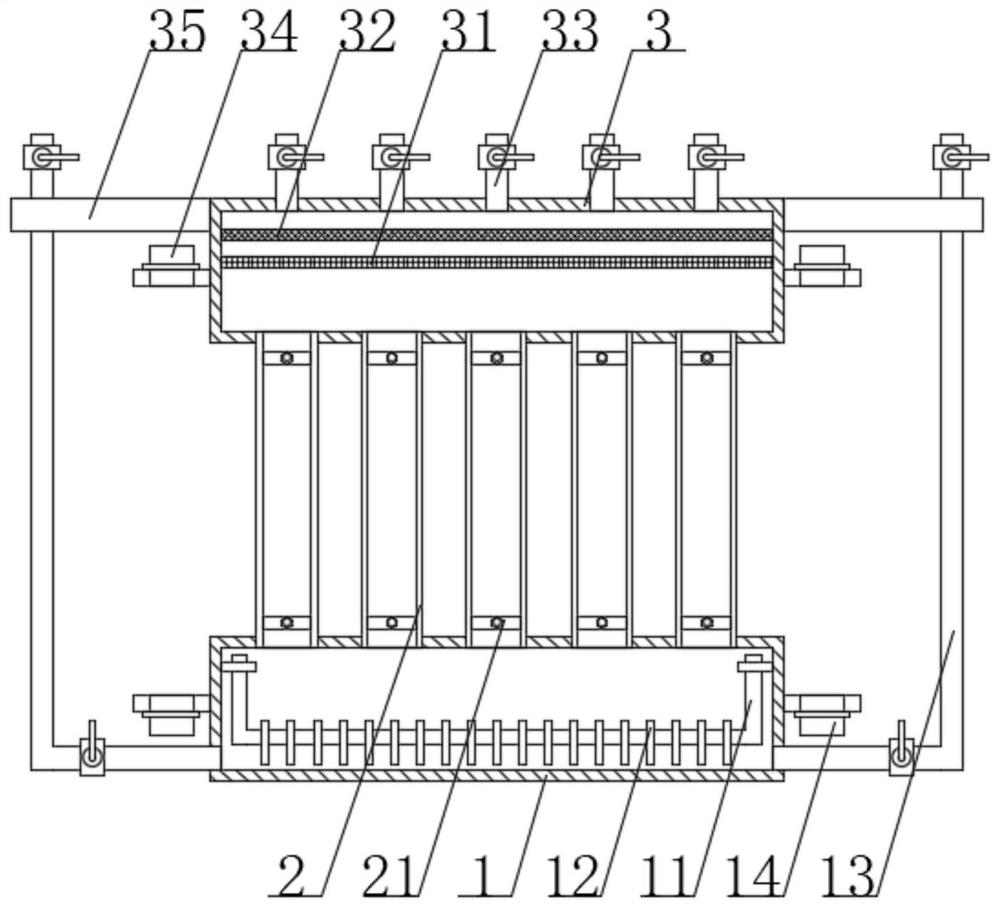

[0026] see Figure 1-6, the present invention provides a technical solution: a steam recovery heat exchange unit in the aerated concrete industry, including a storage box 1, a heat exchange tube 2 and a collection box 3, and the two sides of the inner wall of the storage box 1 close to the top are fixedly connected with heating The heater 11 has a U-shaped structure, and there are three heaters 11, and the distance between any two adjacent heaters 11 is the same, and the three heaters 11 can effectively The gas-liquid in the storage box 1 is heated to increase the activity of the gas-liquid molecules, so that the liquid is converted into a gas, and the activity of the gas is further improved. The middle parts on both sides of the outer periphery of the storage box 1 are connected to the bottom by bolts and the method. The blue is fixedly connected with a delivery pipe 13, the delivery pipe 13 is in an L-shaped structure, the lower surface of the delivery pipe 13 and the lower ...

Embodiment 2

[0028] see Figure 1-6 , the present invention provides a technical solution: a steam recovery heat exchange unit in the aerated concrete industry, including a storage box 1, a heat exchange tube 2 and a collection box 3, and the two sides of the inner wall of the storage box 1 close to the top are fixedly connected with heating The heater 11 has a U-shaped structure, and there are three heaters 11, and the distance between any two adjacent heaters 11 is the same, and the three heaters 11 can effectively The gas-liquid in the storage box 1 is heated to increase the activity of the gas-liquid molecules, so that the liquid is converted into a gas, and the activity of the gas is further improved. The middle parts on both sides of the outer periphery of the storage box 1 are connected to the bottom by bolts and the method. The blue is fixedly connected with a delivery pipe 13, the delivery pipe 13 is in an L-shaped structure, the lower surface of the delivery pipe 13 and the lower...

Embodiment 3

[0030] see Figure 1-6, the present invention provides a technical solution: a steam recovery heat exchange unit in the aerated concrete industry, including a storage box 1, a heat exchange tube 2 and a collection box 3, and the two sides of the inner wall of the storage box 1 close to the top are fixedly connected with heating The heater 11 has a U-shaped structure, and there are three heaters 11, and the distance between any two adjacent heaters 11 is the same, and the three heaters 11 can effectively The gas-liquid in the storage box 1 is heated to increase the activity of the gas-liquid molecules, so that the liquid is converted into a gas, and the activity of the gas is further improved. The middle parts on both sides of the outer periphery of the storage box 1 are connected to the bottom by bolts and the method. The blue is fixedly connected with a delivery pipe 13, the delivery pipe 13 is in an L-shaped structure, the lower surface of the delivery pipe 13 and the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com