Bulletproof armor comprising metal lattice structure

A technology of metal lattice and armor, which is applied in the direction of armor, protective equipment, armor plate structure, etc., can solve the problems of poor defense effect and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

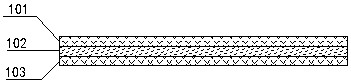

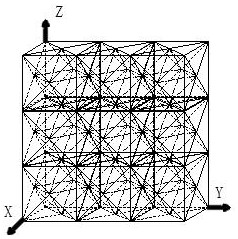

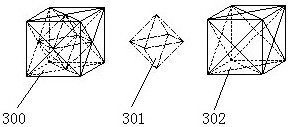

[0026] A type of ballistic armor that includes a metallic lattice structure, such as figure 1 As shown, it includes an upper layer 101, a middle layer 102 and a lower layer 103. The middle layer 102 is a ceramic composite material layer, and the upper layer 101 and the lower layer 103 are metal and polymer composite material layers. The metal and polymer composite material layer is a polymer material. A composite material layer formed by covering a single-layer or multi-layer metal lattice structure. like figure 2 As shown, the metal lattice structure is a flat and regular continuous structure formed by extending and arranging a plurality of cells 300 along the x, y, and z axis directions, as shown in image 3 As shown, the cell 300 of the metal lattice structure is composed of an outer skeleton 302 and an inner skeleton 301. The outer skeleton 302 is a regular hexahedral hollow structure formed by connecting a plurality of ribs, and each surface of the regular hexahedral ho...

Embodiment 2

[0036] The method for preparing the metal and polymer composite layer materials involved in the upper and lower layers of the bulletproof armor may include:

[0037] 1) Using 3D printing, the metal raw material is made into a metal lattice structure, in which the metal lattice structure is a flat and regular continuous structure formed by extending and arranging multiple cells along the x, y, and z axes. The cells of the metal lattice structure are composed of an outer skeleton and an inner skeleton. The outer skeleton is a regular hexahedral hollow structure connected by multiple ribs, and the diagonal lines of each surface in the regular hexahedral hollow structure are also connected with Ribs, the inner skeleton is a regular octahedral hollow structure formed by connecting the intersection points of the diagonal lines of the outer skeleton as corner points by a plurality of ribs, the intersection points of the diagonal lines on each surface of the outer skeleton and the corr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com